National Aviation Day: Looking Back at How Boeing Integrated the 787’s Avionics Systems

(Photo courtesy of Boeing)

In 1939, Franklin D. Roosevelt issued a presidential proclamation designating August 19 as National Aviation Day to commemorate the Wright Brothers’ first flight completed in 1903. As the aviation industry celebrates the day with a wide array of historical facts and figures, we’re re-publishing an article from the Avionics International magazine’s digital/print archives first published in June 2005 analyzing how Boeing constructed the Boeing 787’s avionics systems architecture.

The article was written by former editor-in-chief David Jensen, and he explains how the avionics network came together for the 787 Dreamliner, which first entered passenger-carrying commercial service in 2011. Our coverage from six years prior has been re-published in its original form below, with updated images of 787’s avionics.

Happy National Aviation Day!

B787 Cockpit: Boeing’s Bold Move

By David Jensen | November 1, 2005

It is the most integrated, most supplier-based cockpit, using the largest display system and the most open architecture of any commercial aircraft developed by Boeing. The B787 flight deck also represents a major realignment in the way the airframe manufacturer manages avionics development and production.

EVERETT, Wash., Aug. 31, 2005 — “Boeing worked with airlines and pilots around the world to develop a flight deck that complements the unique improvements featured in the passenger cabin of the all-new 787 Dreamliner. All display formats in the 787 flight deck are the same as in the 777, including the flight management computer pages the overhead (systems controls) layout is identical the autoflight mode control panel layout also is identical. Key features of the Dreamliner flight deck include larger displays, dual head-up displays and dual electronic flight bags.” – Boeing Commercial Airplanes

To save weight and space, Boeing has called for fewer wires and greater integration of subsystems. (The company plans to make the B787’s avionics suite 2,000 pounds [907 kg] lighter than earlier-generation systems.) And to save acquisition costs and exploit economies of scale, it chose to standardize the avionics package. No longer will Boeing’s airline customers receive an unequipped airplane and then select the avionics systems piecemeal. Rather they will receive a comprehensive package that incorporates new standard systems, such as dual head-up displays (HUDs) and dual electronic flight bags (EFBs), plus an architecture that will readily accommodate the addition of new functions and upgrades.

Rockwell Collins is probably the biggest beneficiary of Boeing’s new philosophy and development of the B787. Although it played a major role in equipping the B737 Classic, B757 and B767, Collins’ largest enterprise with Boeing, in terms of line replaceable units (LRUs) and in engineering, is unquestionably the B787 program, according the Greg Irmen, Collins’ senior director of Boeing programs. The electronic systems supplier and integrator stands to gain up to $3.5 billion over the life of the B787 program.

A Systems Integrator

Collins also is a B787 systems integrator. It, rather than Boeing, will be gathering large sections of the flight deck subsystems to produce system packages–work that will take place in a specially built lab in Cedar Rapids, Iowa. The packages then will be delivered to Seattle in modules for installation in B787 airframes. Collins’ work represents a major part of Boeing’s new philosophy of having first-tier suppliers carry out most of the B787’s integration work.

“A lot of equipment below the flight deck used to be sent to Boeing in hundreds of pieces for assembly,” says Irmen, referring in this case to the pilot controls. “Now we will provide just a few modules.” The B787’s pilot controls will consist of just four modules: the control stand assembly, pitch control assembly, lateral control assembly, and yaw control/brake assembly.

In addition to being a systems integrator and pilot control supplier, Rockwell Collins will provide the B787’s displays and crew alerting system, communications radios, and the surveillance system. Smiths Aerospace will supply the B787’s Common Core System (CCS) that provides the processing, network and input/output (I/O) resources to many aircraft functions. And Honeywell will provide the B787’s navigational package, terrain awareness warning system (TAWS), flight management system (FMS) and fly-by-wire system.

Like the B777—Somewhat

Although the B787 cockpit represents a major shift in development and design, it also is meant to provide commonality with the B777 flight deck, to facilitate transition training. (Boeing’s goal is for B777 pilots to train no more than five days for B787 transition.) This commonality posed unique challenges for Collins. “One of the biggest challenges was the check lists; we wanted to make sure the check lists in the two aircraft are extremely common,” says Irmen.

“The other area that’s a challenge is the pilot controls,” he adds. “We’re working to make the feedback from the 787 controls feel the same as in the 777. In other words, we’re working to duplicate the force feel curves for each axis: pitch, yaw and roll.” Rockwell Collins Electroprecision in Irvine, Calif., is developing the B787 pilot controls.

A major distinction between the two aircraft cockpits is the display size. The B787 boasts five 15.1-inch diagonal, liquid crystal displays (LCDs)–twice as large as the B777’s screens. The B787 will be the first commercial aircraft to be equipped with these large displays, although they may be installed in a government/military aircraft prior to the the Dreamliner’s scheduled entry into operation in 2008. “We’re working on another program on the government side,” says Irmen, adding that he could provide no further details of potential display system orders.

The B787 has two primary displays and two navigational displays for the two pilot positions and a display in the center console, also referred to as the “aisle stand.” All displays are in landscape format. The center display “is where the pilot and copilot do their flight management activity and route planning,” says Irmen. “There is a keyboard and cursor control [a scratch pad] on either side of the display, and each pilot can enter data independently.”

The large, 12-by-9.1-inch displays provide the obvious benefit of better pilot viewing, but Collins also selected the size to protect against obsolescence. “The displays are commercial glass [provided by Japan’s Sharp Corp.]; they’re the same LCD as you use with your laptop, only enhanced,” says Irmen. “We think laptops with screens that size will be around for a long time.” For aviation use, those screens will be ruggedized.

The large displays can present more information. One new feature that Collins plans for the B787 panel displays is the presentation of airport surface maps. These graphical displays will be able to show ownship position on the runways and taxiways. “As we progress and improve the technology, we could also use the onboard radar and transponder to show the surface traffic and obstacles on the surface map and perhaps provide runway guidance,” Irmen adds.

Surface maps could, of course, also appear on the B787’s two electronic flight bags. However, the extent to which the EFBs interface with onboard systems–most notably the FMS–is still under discussion, says Irmen.

As in the B777 and the newest version B737, the EFB hardware for the B787 will supplied by Astronautics Corp. of America and the software, by Jeppesen, now part of Boeing.

Offering the B787 pilots further situational awareness are the two head-up displays, furnished by Rockwell Collins Flight Dynamics, in Portland, Ore. In addition to primary flight display (PFD) symbology—attitude, altitude, airspeed, etc.—the B787 HUDs also will present windshear warnings and escape guidance, as well as “some takeoff cues” for guidance when visibility is limited, according to Irmen.

EVERETT, Wash., June 20, 2008 – Boeing [NYSE: BA] has completed Power On for the first 787 Dreamliner. The test sequence lasted for just over a week and proved the functionality and installation of the airplane’s electric systems.

Running tests in the flight deck are (from left) James Townsend, aviation manufacturing technician inspector; Allen Smith, test technician; Jon Stephenson, production test manufacturing engineer; and Riger Vazquez Jr., production test team leader.

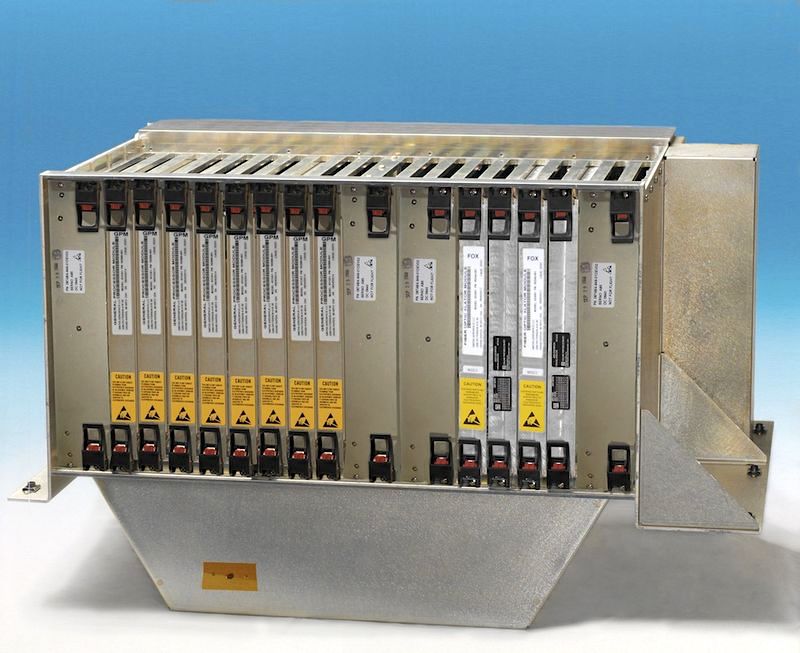

The CCS

The B787’s nerve center is its common core system, which Smiths Aerospace refers to as an “open architecture platform,” with the ability to adopt new applications not unlike a desktop computer. Hosted functions–for example, flight management–utilize the processing, network and input/output resources provided by the CCS in a similar manner that desktop computer applications use the processor, operating system and peripherals.

The CCS consists of three major elements: processing resources to execute hosted function applications software; the common data network (CDN) that provides reliable communications between processing, I/O and function-specific equipment; and remote data concentrators that provide gateways to analog, discrete, controller area network (CAN) bus , and legacy ARINC 429-based equipment. For specialized functionality—for example, graphics generation—hosted functions can implement special modules that interface to the CCS, based on an open standard network interface.

Smiths distinguishes the CCS’ distributed open architecture from the federated systems of past. Instead of each LRU’s having its own processing, infrastructure, I/O and internal bus, the CCS has common processing with “robust” partitioning, a common infrastructure and distributed system bus.

Robust partitioning means not just separating the software, according to Gerry Vossler, Smiths’ vice president of advanced marketing and technology. “The system is proven to maintain partitions robustly over the processing, the network and, to some extent, the I/O,” he explains.

The open architecture facilitates the addition of new applications. It accommodates upgrades and allows Boeing freedom in selecting the best providers of subsystems, says Vossler. To develop a new system for the B787, the vendor need only know the specifications for the power and the AFDX network interfaces, which apply the ARINC 653 standard.

“With ARINC 653 you know how to communicate [with the CCS]. Every supplier [for the B787] does it the same way; there’s no ambiguity,” Vossler maintains.

Recognizing that in many cases some processing has to reside in the individual LRU, Boeing nevertheless has set a goal to have as much onboard processing as possible performed by the CCS. In fact the CCS hosts even the flight management system function.

The CSS performs most of the processing for the B787’s display system, as well. “There is a very tight integration between our displays and the CCS,” says Collins’ Irmen. “The majority of the display applications are run on the general processing modules of the CCS. The display information is then sent over to our graphics generation module [GGM], housed in the CCS cabinets. It’s sent using ARINC 661 [standard for flight deck display interface] over Ethernet, where it is formatted for display and sent to the displays over a pixel bus. Other systems, such as the CISS [configurable integrated surveillance system], also generate display information and send it to the GGMs over ARINC 661 for display.”

Some systems on the B787 do retain their own processing, however. And the challenge, Vossler, observes, is determining how the processing is divided between the LRU and CCS. For example, in the anti-skid braking system, rapid processing is required but only during a brief interval of the flight. “So you would have all of the fast processing done locally in the LRU,” he says.

The B787’s CCS processing resources are comparable to the core processor that Smiths developed for the C-130 AMP (Avionics Modernization Program). Both use the ARINC 653 standard, and both employ the same real-time operating system, Wind River Systems’ Platform Safety Critical for ARINC 653 (PSC). But while the C-130 system incorporates about seven applications, the CCS can accommodate up to 100 applications. Vossler attributes the difference to the CCS’ increased processing power and networking bandwidth plus the fact that some C-130 functions may require more processing resources. He adds that the B787’s CCS will initially amalgamate about 70 applications for 20 to 25 suppliers.

The 787’s common core system (CCS) (Photo courtesy of GE Aviation)

A key element of CCS is the common data network (CDN), a deterministic Ethernet avionics duplex switched (AFDX) network, using ARINC 664 protocols and standards. Collins provides Smiths the CDN’s elements: the network switches and end systems. The CDN connects the processors, the remote data concentrators and specialized LRUs, using fiber or copper connections.

To support the distributed nature of CCS, network switches are located in the common computing resources (CCR) cabinets and are mounted throughout the aircraft.

RDCs—Reducing Wires

The CCS also incorporates remote data concentrators (RDCs), which are distributed throughout the aircraft and serve as digital gateways for the B787’s various functions. They are gateways for analog, discrete, ARINC 429 and CAN bus data off and on to the CDN.

Among other benefits, the RDCs reduce the amount of wiring in the B787. Instead of each function being linked (often by long wires) directly to the CCS, a group of functions is connected by short wires to the local RDC, which, in turn, is linked to the CCS via AFDX cable. The use of RDCs is similar to the use of USB-based devices on a personal computer, but now they are distributed. The RDC distributes the I/O interface, removing it from the electronics rack, says Vossler.

The B787’s forward electronics bay houses the CCS in two common computing resource cabinets. The dual cabinets don’t represent the system’s redundancy, however. Vossler explains that the redundancy on board the aircraft is based on the overall architecture, combining a set of high-integrity processing resources, a high-integrity network, and distributed remote I/O devices (RDCs). “The CCS provides the resources to the meet the function’s integrity requirement,” he adds.

As a key component of the Smiths common core system, Rockwell Collins is providing the common data network, which joins the B787’s less critical systems. Indeed, it has a firewall that isolates the less critical applications, such as cabin systems, from the highly critical flight deck systems. Essentially an onboard server, the common core network has room for five file server modules, each with processing power equivalent to a PowerPC, says Collins’ Irmen. The module can host various applications:

- One module hosts the aircraft’s health management data load system; it allows the secure transfer of maintenance data to a ground-based laptop or data loader, or over a data link.

- One module is available to host the Connexion by Boeing broadband data link service.

- One module hosts Boeing Commercial Aviation Services (CAS) software, used to provide, for example, in-flight entertainment system or other marketing data.

- The remaining two modules are open to the airline’s use at its discretion.

Com/Nav/Surveillance

Collins will supply Boeing’s new aircraft its CISS 2100 configurable integrated surveillance system, which combines the processing for the weather radar, Mode S transponders, TAWS, and traffic alert collision avoidance system (TCAS) in a single cabinet in the electronics bay. Honeywell supplies the TAWS, and Collins provides its PMR-2100 MultiScan weather radar and transponders. The CISS processor gathers radar data over a fiber optic line and then processes the weather information along with the TAWS and TCAS data for presentation on one of the cockpit displays. The pilots can select various options in the radar and TCAS independently.

The Collins communications package includes the VHF 2100 radio, which is VHF digital link, Mode 2 (VDL-2)-capable and can be upgraded to accommodate VDL-3, according to Irmen. He adds that the company is investigating an upgrade to VDL-4, as well. Rounding out the B787 com package is the HFS-900C HF radio and the SAT-2100 satellite communications radio, offering three voice channels and the capability of adding Inmarsat’s data service.

In addition to the flight management function, Honeywell will supply the following navigation equipment for the B787:

- Inertial reference system (IRS),

- Air data system,

- Two DME radios,

- Two radar altimeters,

- Emergency locator transmitter, and

- Two integrated nav receivers (INRs), each containing an ILS (localizer and glideslope), marker beacons, VOR, GPS and GPS landing system (GLS). The INRs provide capability for Category IIIB ILS and Cat I GLS approaches.

Honeywell also provides the B787’s two attitude heading reference systems (AHRS), capable of attitude and heading in the remote case that the aircraft has a dual IRS failure.

Boeing 787 Customers

The folks at Boeing have been working diligently to both develop and market the new twin-aisle aircraft, the B787. In late April it unveiled the aircraft’s final exterior design. Major assembly of the first aircraft is to begin next year, and first flight is scheduled for 2007, followed by initial deliveries in 2008.

Since it announced its launch customer, All Nippon Airways, in April 2004 Boeing has accumulated firm orders and commitments for 273 aircraft from 23 airlines in four continents: Africa, Asia, Europe and North America. The first North American operator of the B787 will be Northwest Airlines, which ordered 18 aircraft. The following are the B787 customers plus their combined commitments and firm orders:

- Air India 20

- Air New Zealand 2

- All Nippon Airways 50

- Blue Panorama 4

- Continental Airlines 10

- Ethiopian Airlines 10

- First Choice Airways 6

- Garuda Indonesia Airlines 19

- Icelandair 2

- Japan Airlines 30

- Korean Air 10

- LOT Polish Airlines 7

- Northwest Airlines 18

- Primaris Airlines 20

- Royal Air Maroc 4

- Vietnam Airlines 4

In addition, Boeing has booked a firm order for six aircraft from an unidentified customer and has commitments for 36 aircraft and firm orders for 24 aircraft from a group of six Chinese airlines. In total, Boeing had, in September, commitments for 99 B787s and firm orders for 174 B787s.

The post National Aviation Day: Looking Back at How Boeing Integrated the 787’s Avionics Systems appeared first on Aviation Today.

—————

Boost Internet Speed–

Free Business Hosting–

Free Email Account–

Dropcatch–

Free Secure Email–

Secure Email–

Cheap VOIP Calls–

Free Hosting–

Boost Inflight Wifi–

Premium Domains–

Free Domains