ORLANDO, Fla. — Over 30 companies presented at the New Product Introductions session at the AEA (Aircraft Electronics Association) Convention in Orlando this week.

Daniels Manufacturing Corporation

Shane Leary, Business Development Manager at Daniels Manufacturing Corporation, showcased their LaceLok Cable Lacing Fasteners product. DMC manufactures application tooling for the aircraft and aerospace industries. The LaceLok product is designed to replace cable ties and hand-tied lacing tape to offer secondary support of wire harnesses. Leary noted that it prevents inconsistent installations, increases safety, and offers more consistency.

Mid-Continent Instruments and Avionics

Ryan Reid, Account Manager, STC and Distribution/Chief Pilot at Mid-Continent Instruments and Avionics, presented the new FLEX Digital Standby Package, including an attitude indicator, counter drum encoding altimeter, and airspeed indicator.

The company also has new TB14 and TB28-12V lithium-ion batteries. According to Brett Williams, Vice President of Engineering, these are lightweight and long-lasting. Williams mentioned that their AML STC is “right around the corner.”

The TB28-12V advanced lithium-ion battery (Photo: True Blue Power)

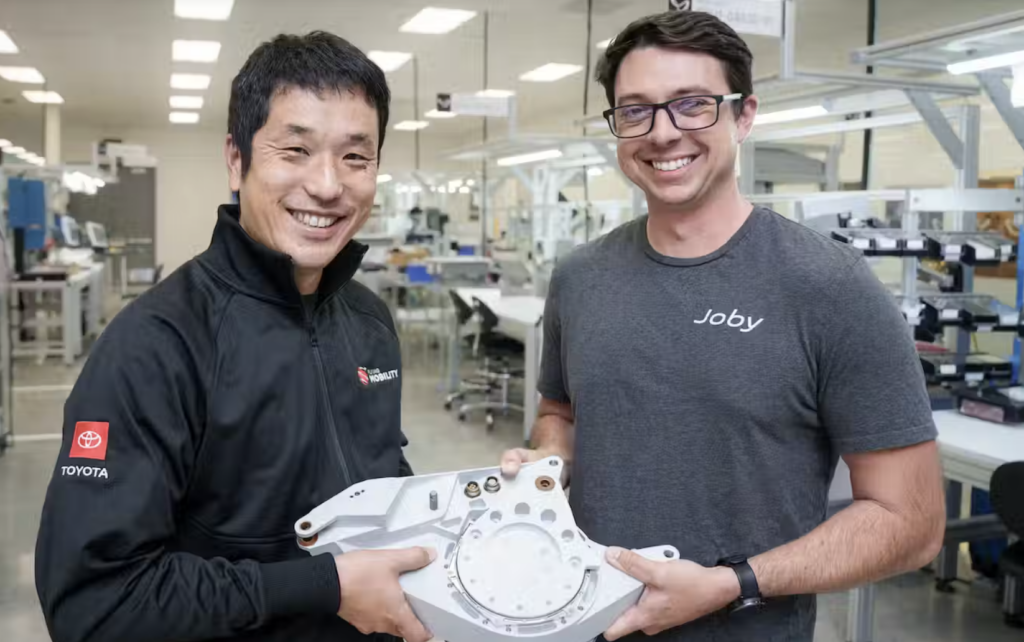

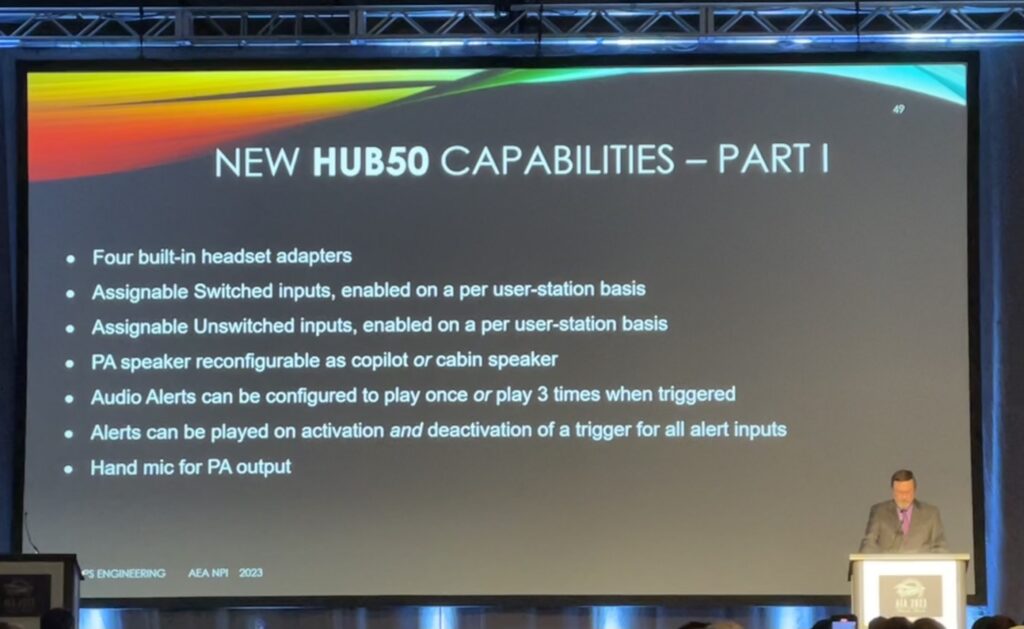

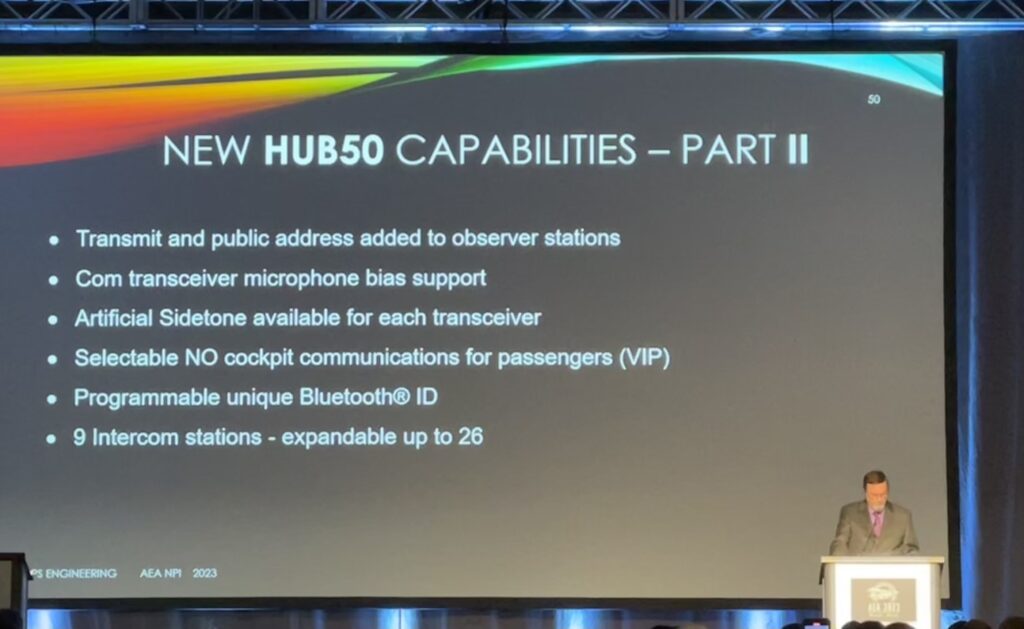

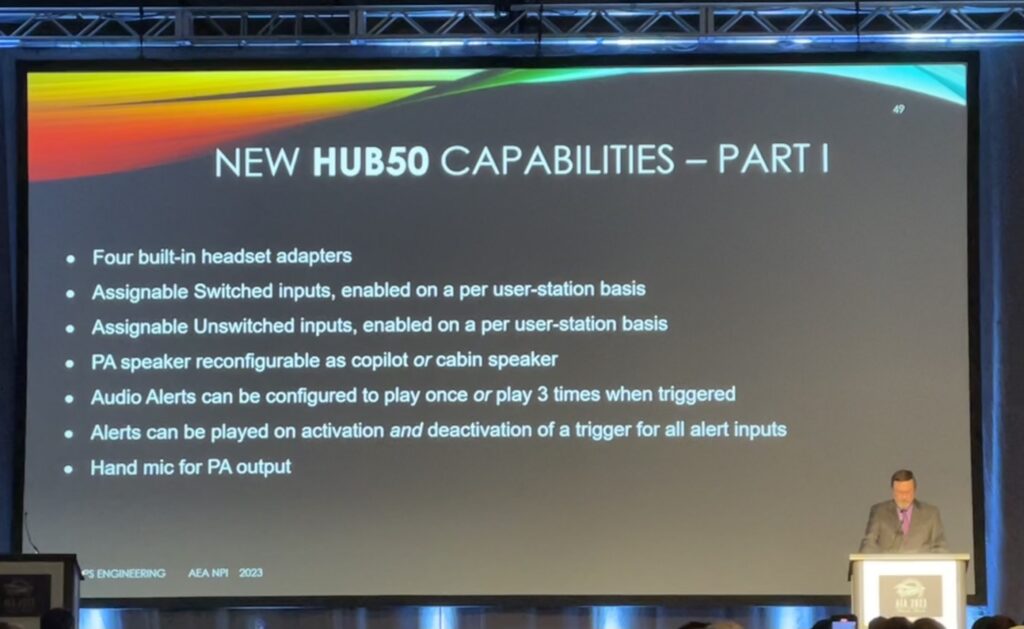

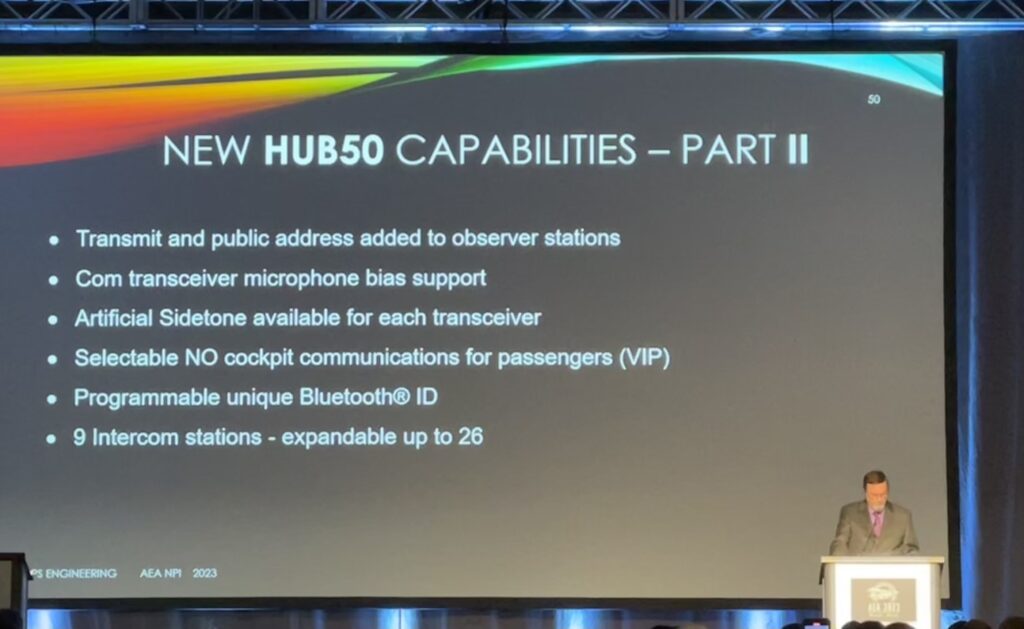

PS Engineering

Gary Picou, VP of Engineering at PS Engineering Inc., discussed the new HUB50 audio management system, which was first revealed at Heli-Expo. The HUB50 offers configurations of more than 250 different parameters and does not rely on adapters or memory modules, according to Picou. There are also some system improvements made to the PAC45, including expandable intercom stations to 20 seats; day/night mode lighting adjustments; and a new user configuration DIP switch for PAC45/PAC45D series.

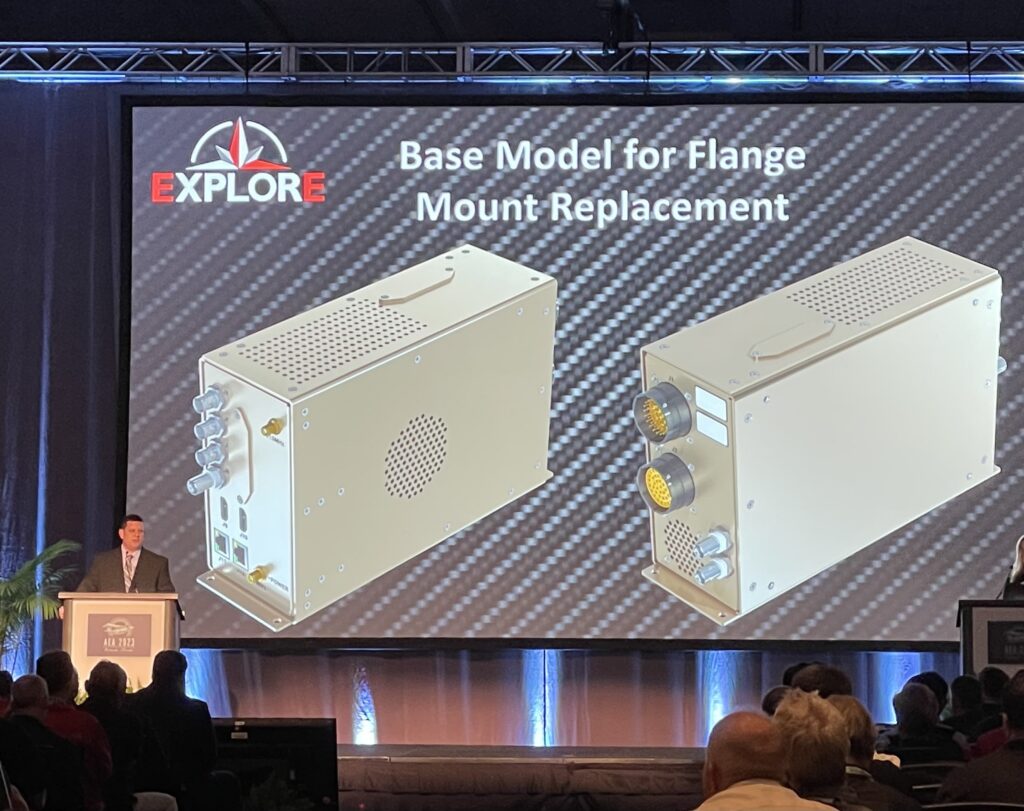

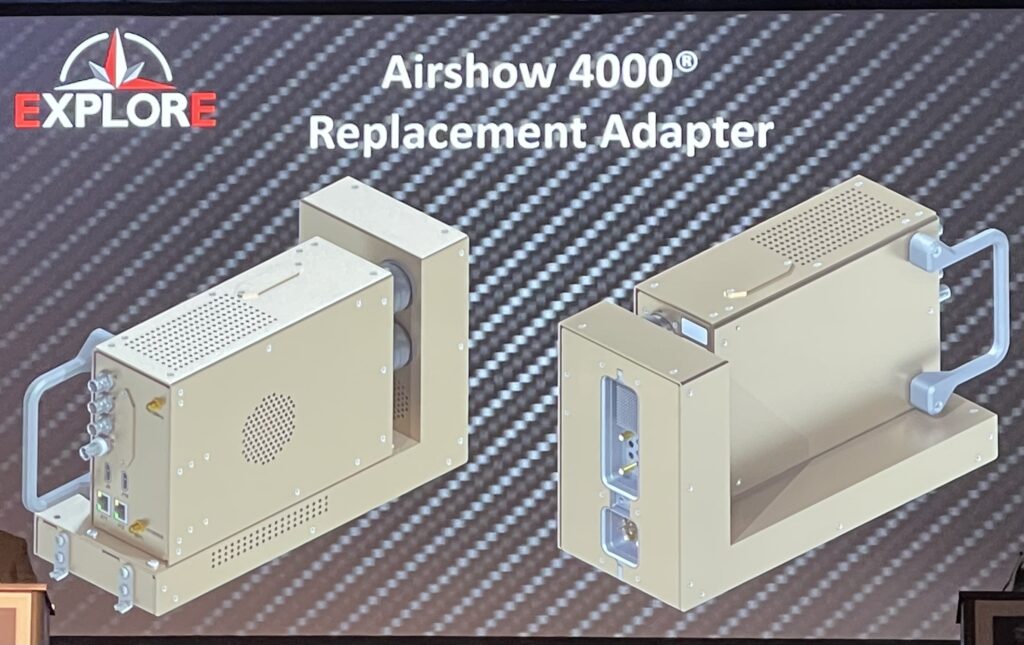

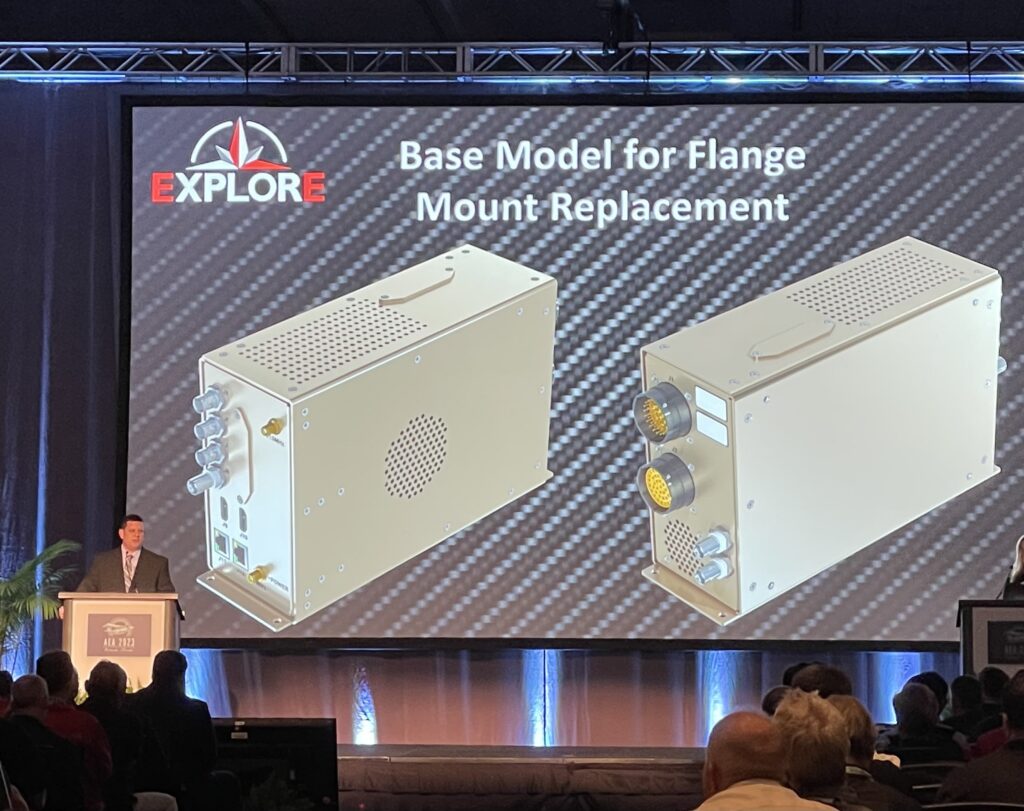

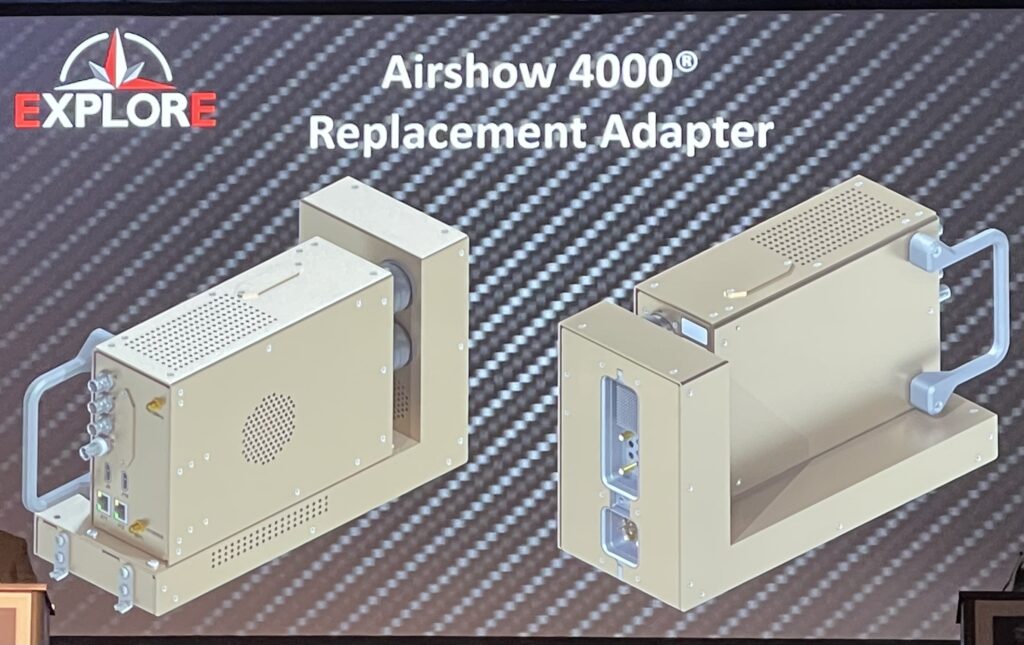

Cabin Management Solutions

David Feuerhak, Vice President of Sales at CMS, introduced EXPLORE, a next-generation 3D interactive moving map. He noted that it allows for custom configuration of flight information pages.

EXPLORE offers both Ethernet and optional Wi-FI for PED (personal entertainment device) interface. In the third quarter of 2023, CMS will also offer an optional flight deck controller.

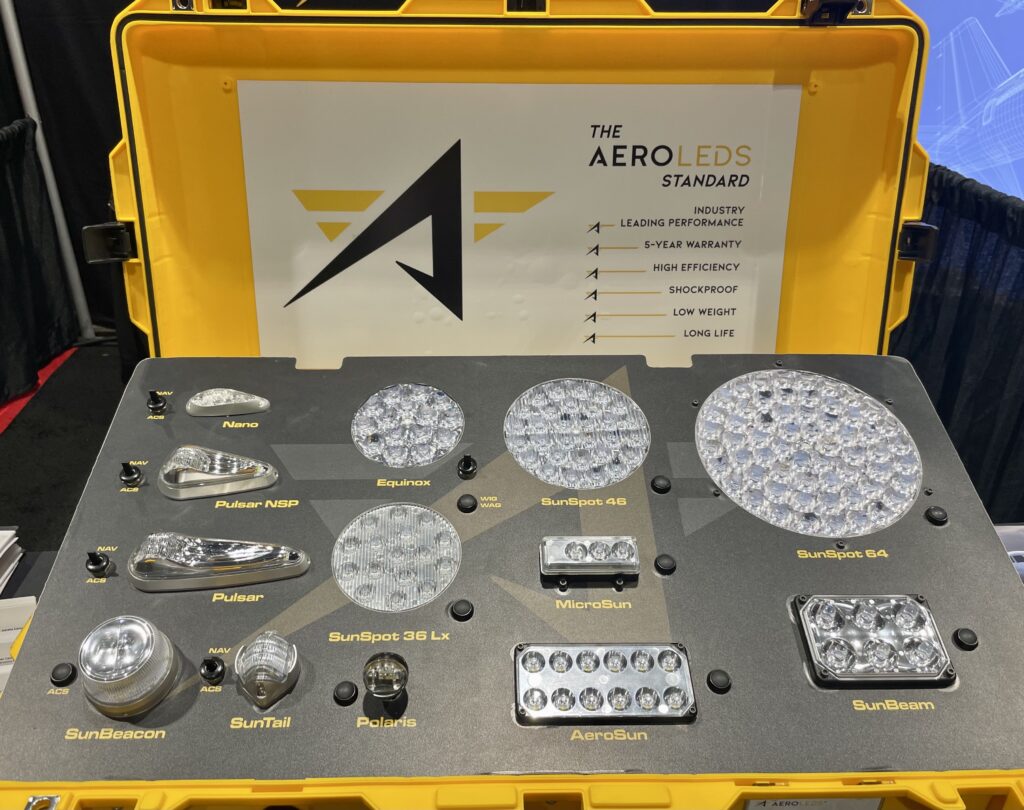

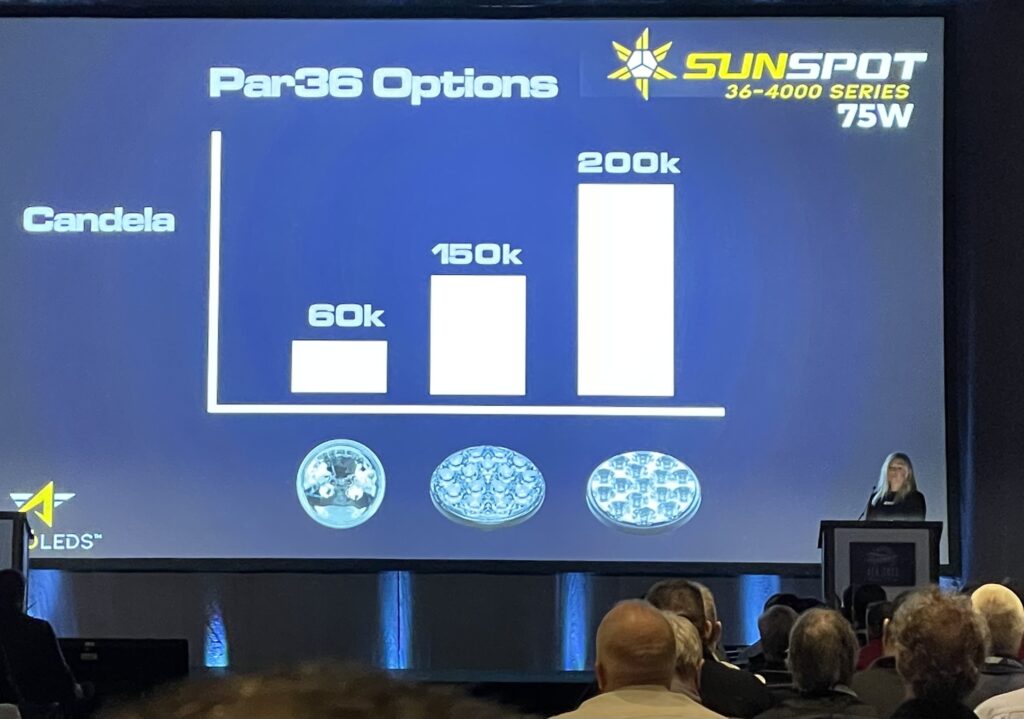

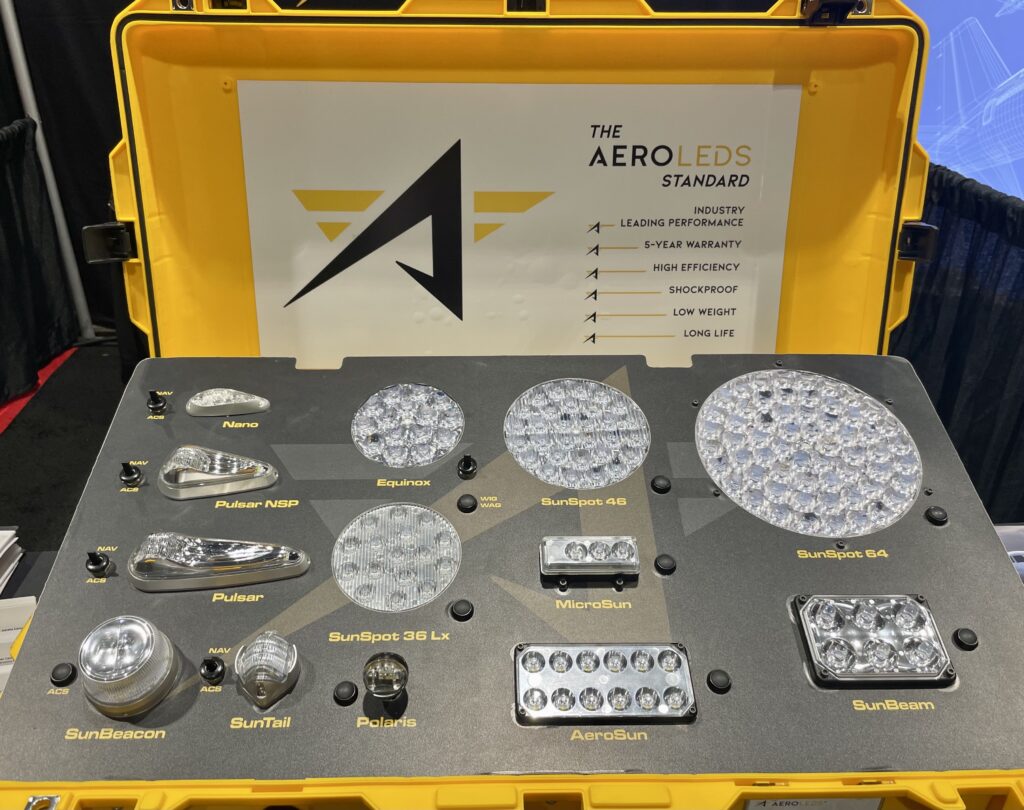

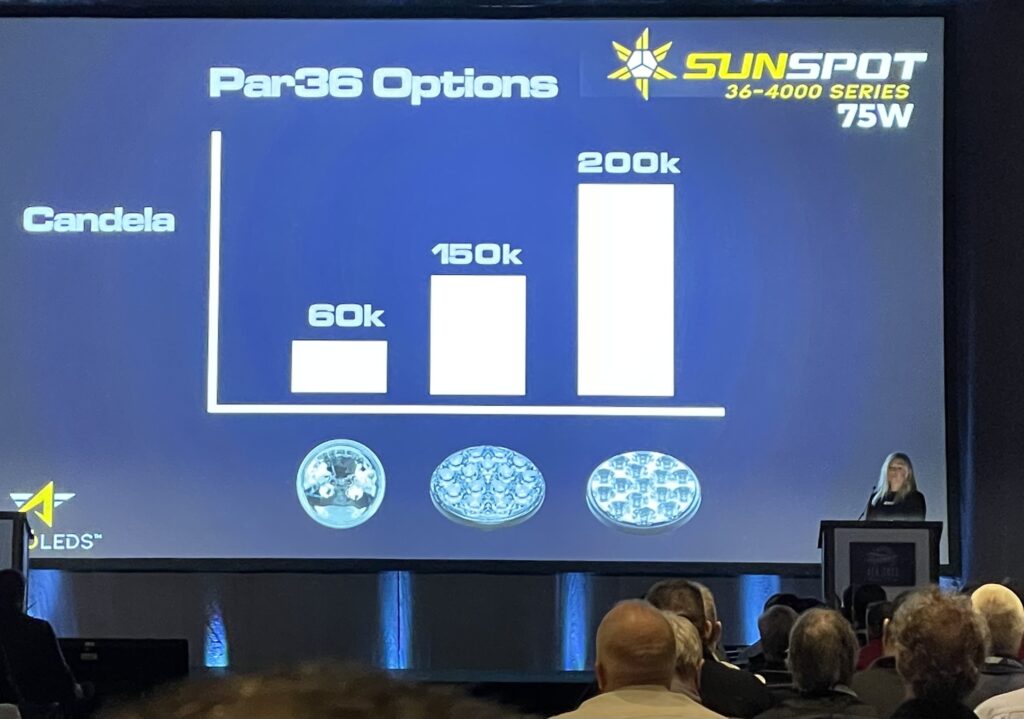

AeroLEDs

AeroLEDs provides LED aircraft lighting solutions. The company announced the new SUNSPOT 36-4000 Series 75W LEDs at the AEA Convention. The product has previously been offered with 45W and 100W options. The 75W version boasts 200,000+ candela, the industry’s highest candela for a PAR36 LED landing light.

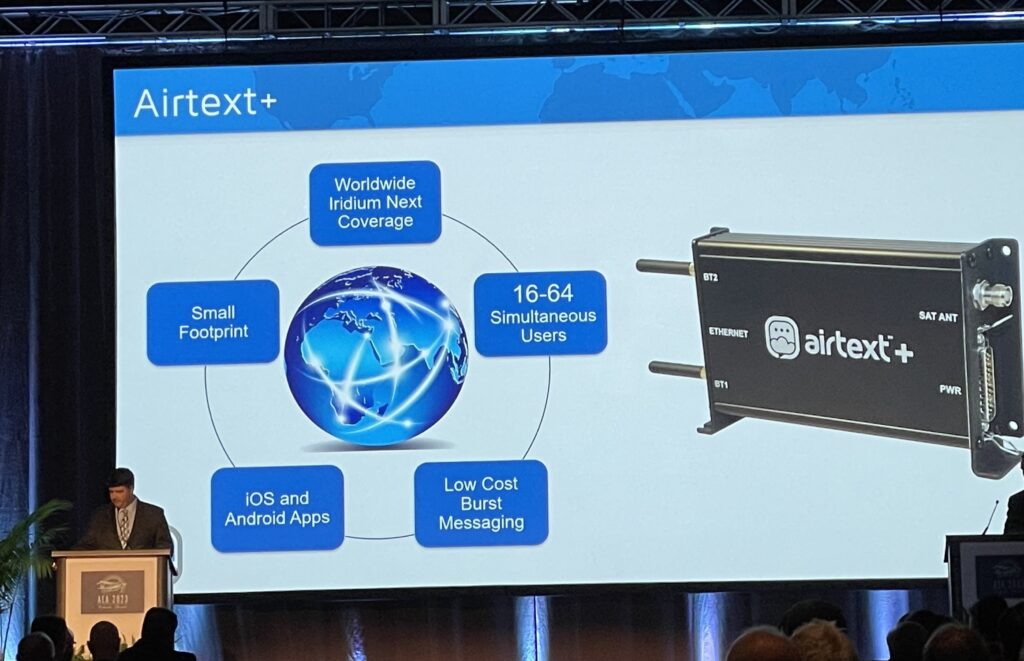

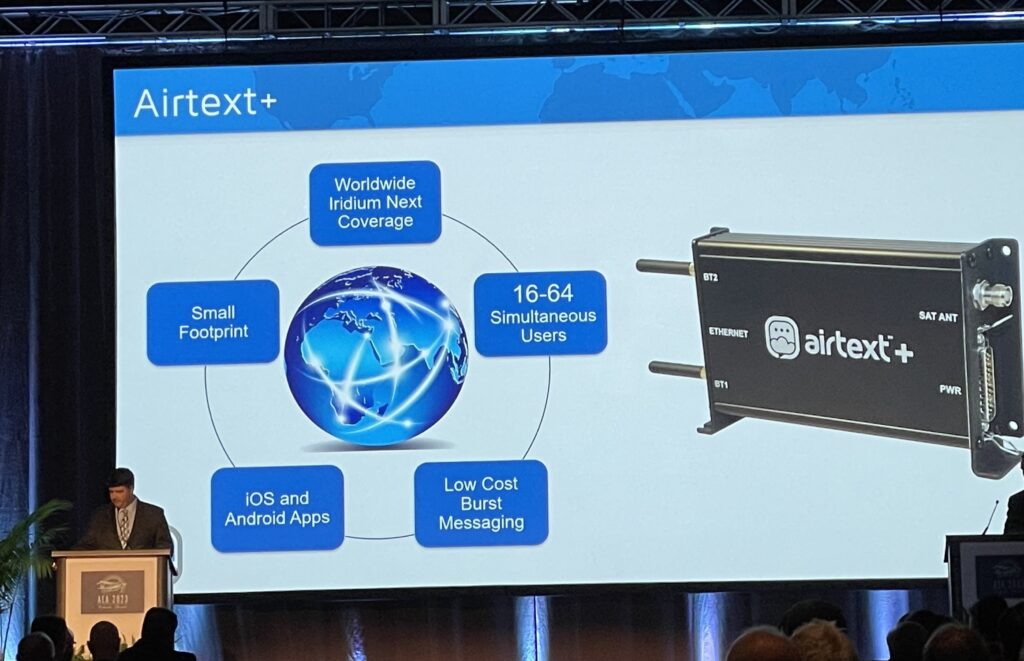

Airtext

Jonathan Pinson, General Manager of Airtext, introduced Airtext+, ideal for offering an internet alternative at a lower installation cost and with lower usage fees. It can be used to offer supplemental connectivity for large aircraft, or aircraft with international operations, and is also valuable for use in smaller aircraft. Airtext has also developed a new 14.6″ Bulkhead Moving Map along with a new Bluetooth handset for cabin audio calls.

Another new offering from Airtext to enhance the passenger experience is the “Oasis Above the Clouds,” or OATC. It provides a simple interface to control and explore cabin amenities as well as a Wi-Fi interface without requiring an internet connection and antenna. According to Pinson, it provides a way to put new technology into an aging airframe.

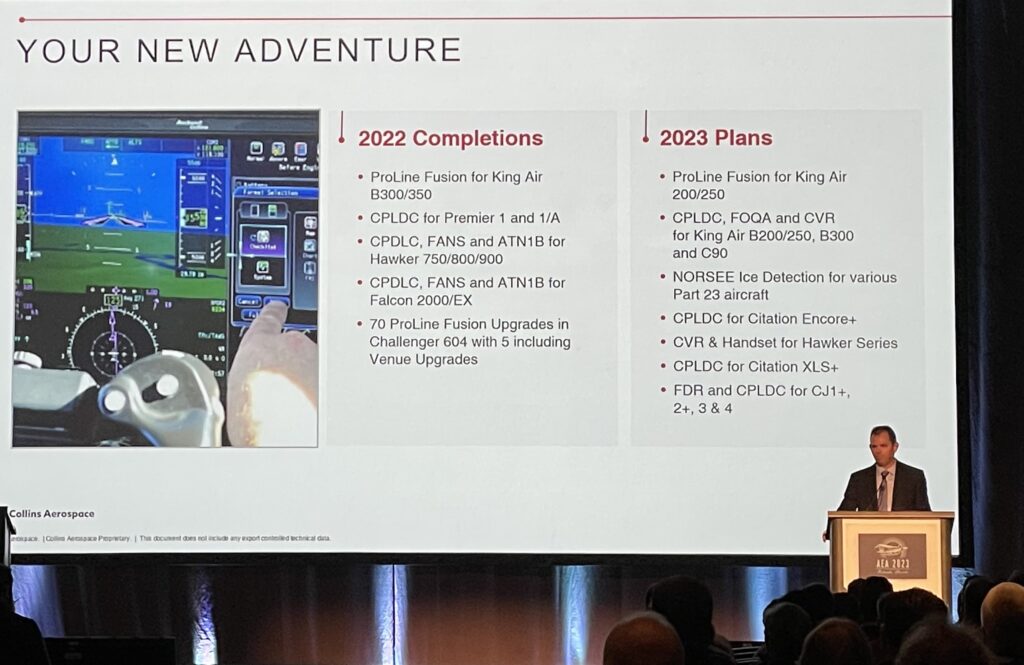

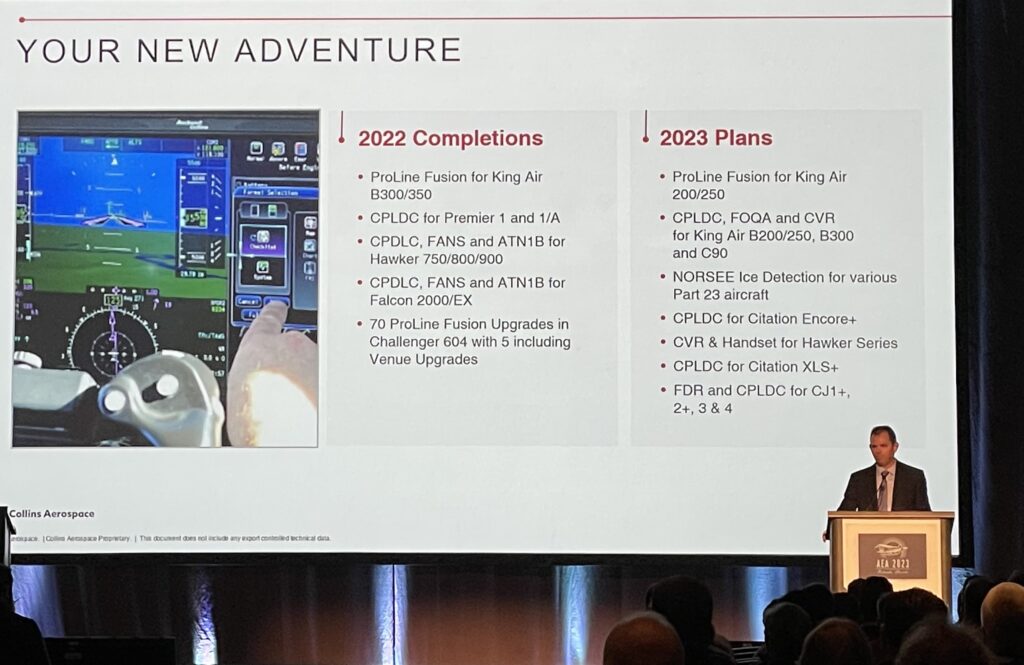

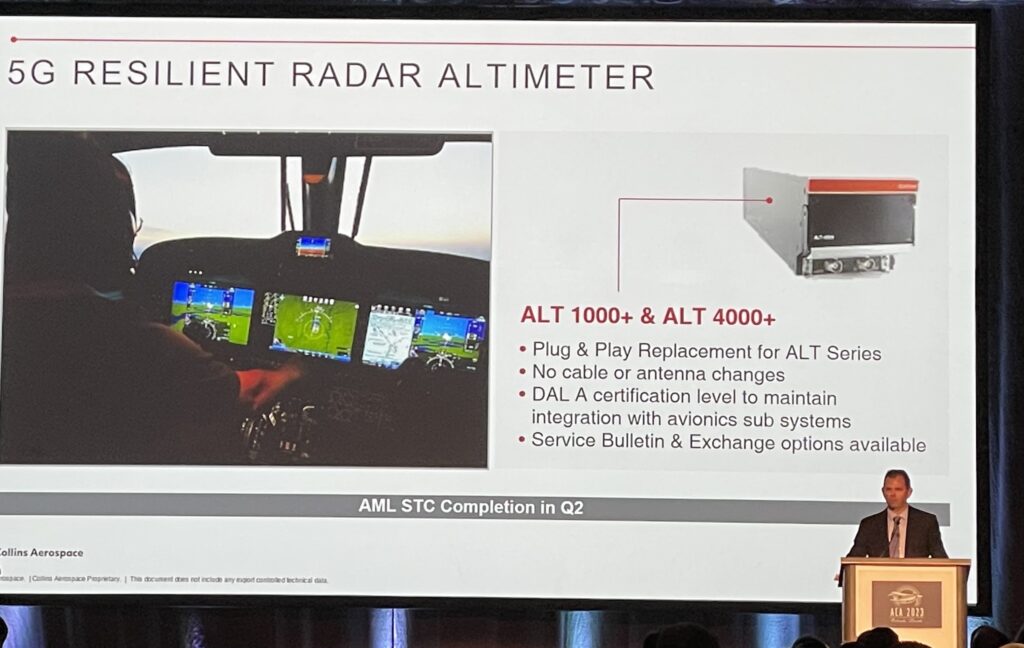

Collins Aerospace

Marc Ayala, Senior Director of Business & Regional Avionics Sales at Collins Aerospace, talked about the company’s plans for 2023 as well as its achievements in 2022.

Ayala announced a cabin management upgrade that will be available later this year—the WAP-6000 (wireless access points). The product maximizes 4K streaming and high-definition content for multiple devices. It is Wi-Fi 6 capable. and there is an option for remote mounting.

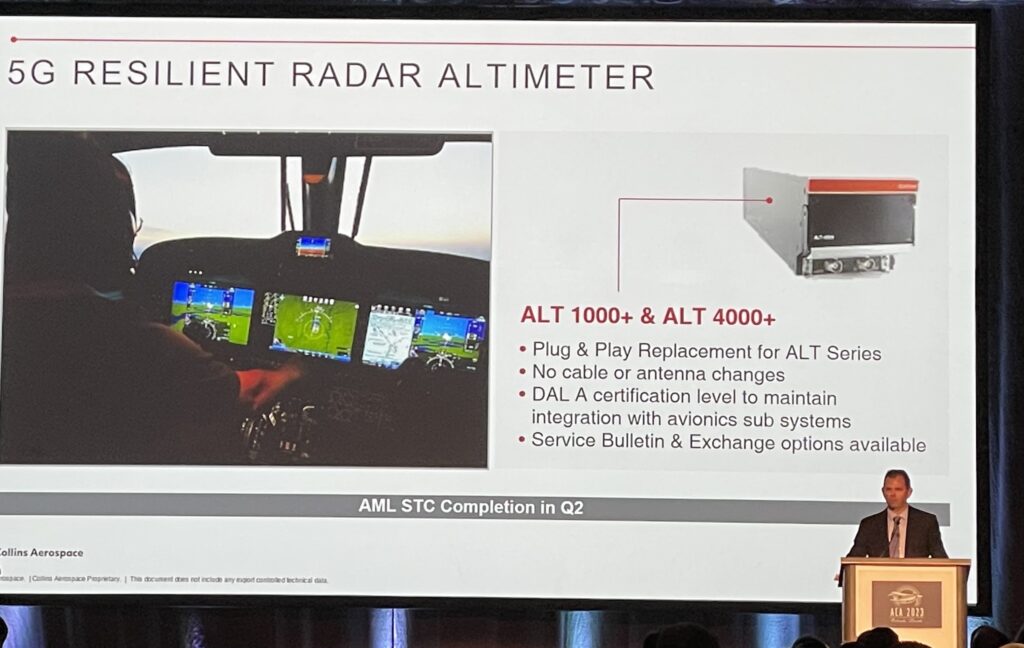

Collins also expects to complete the AML STC in Q2 of this year for its 5G resilient radar altimeters, ALT 1000+ and ALT 4000+. Also available in the second quarter of this year is Collins’ mobile application that enables a connectivity ecosystem for business jets. The application allows for predictive maintenance and offers flight data analytics in real-time.

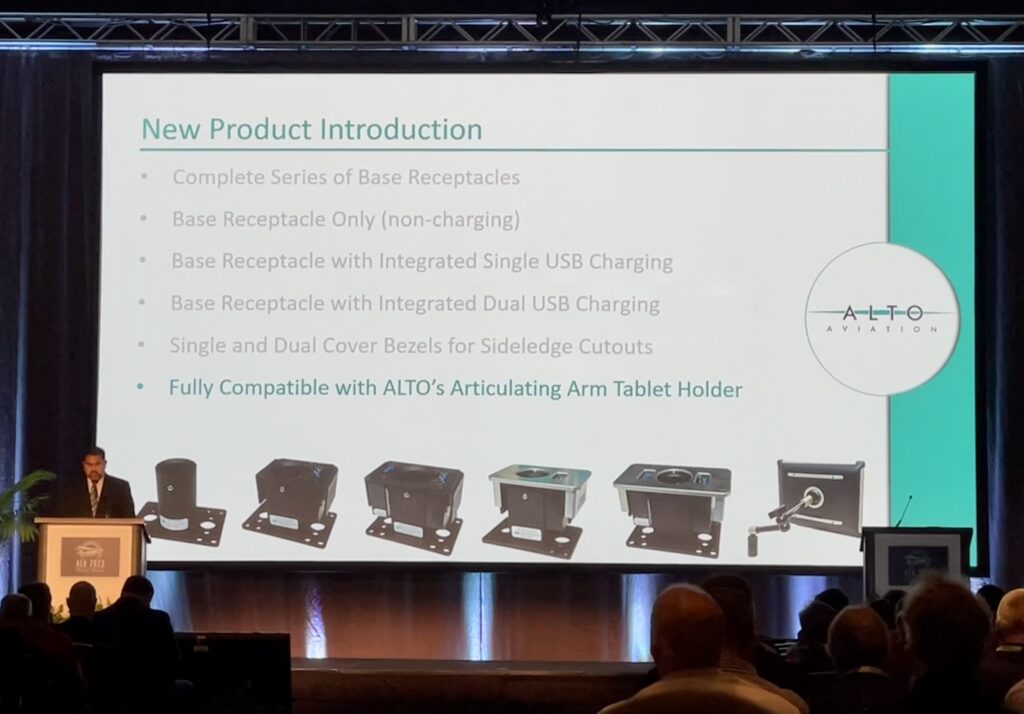

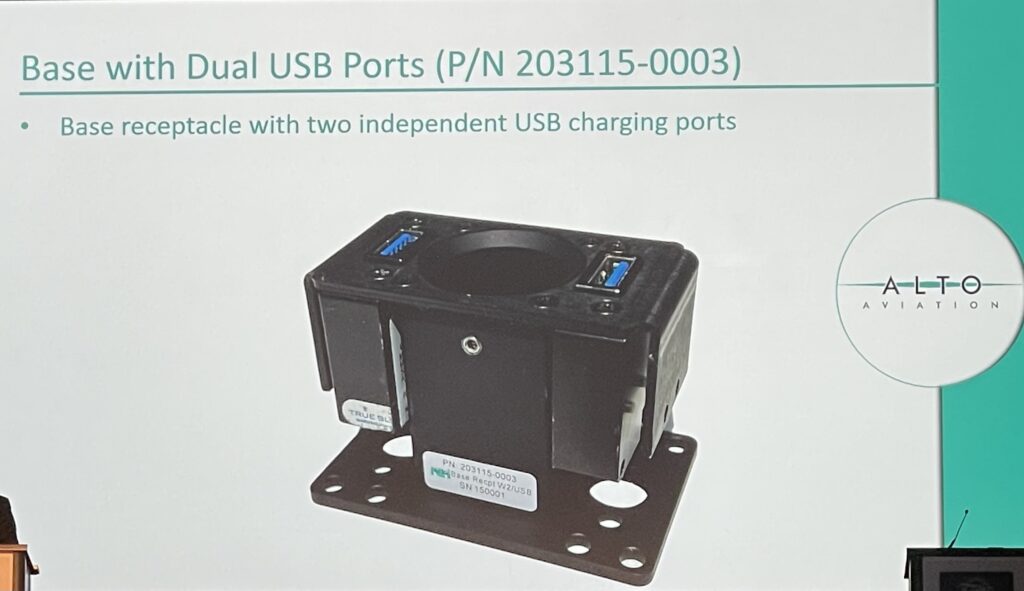

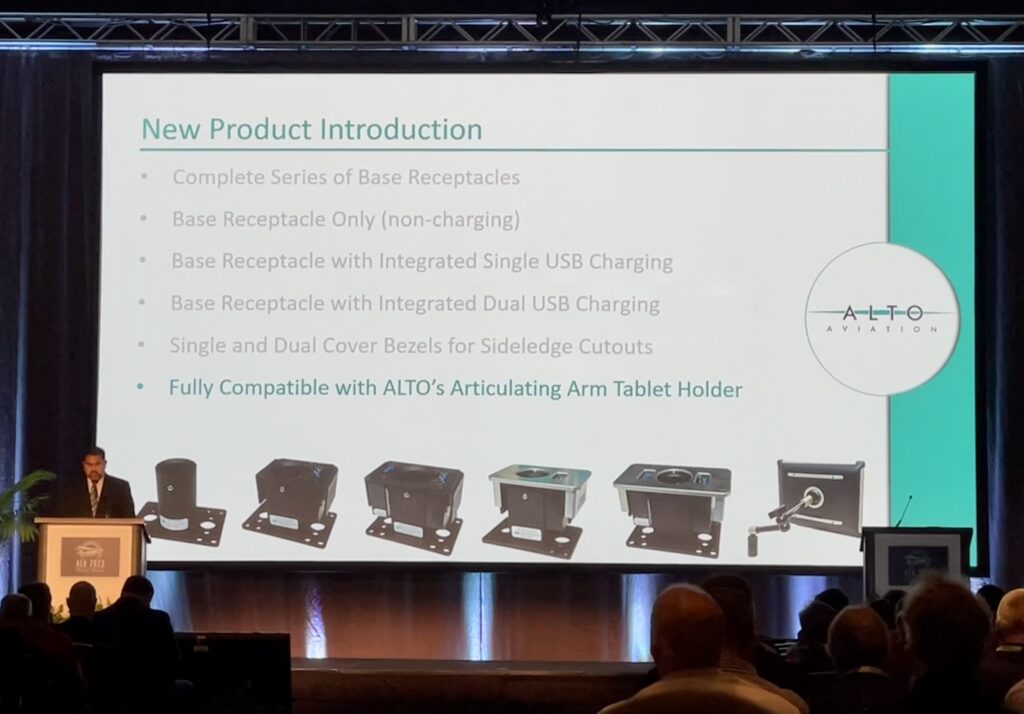

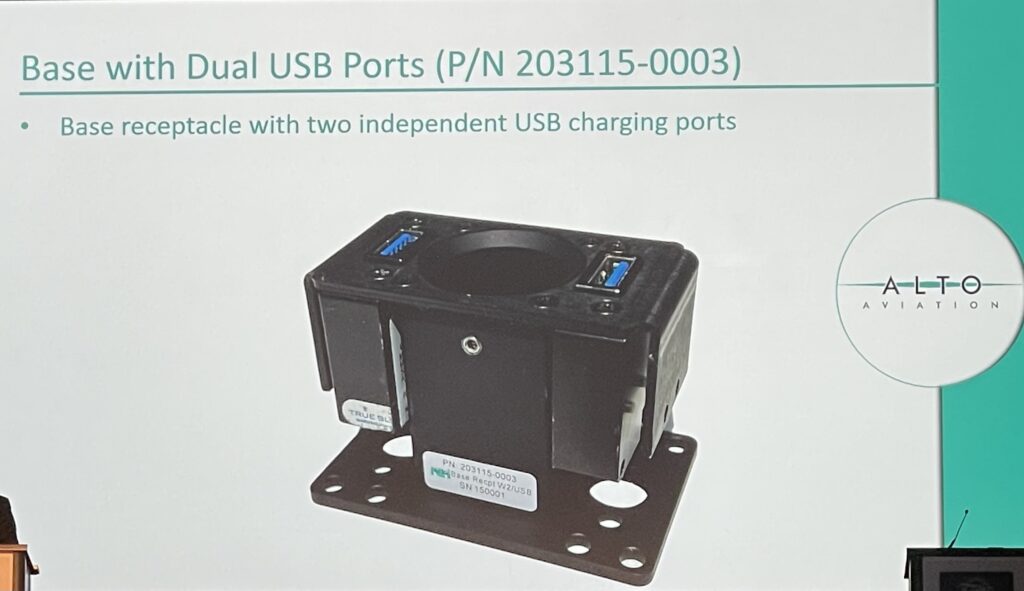

ALTO AVIATION

VP of Sales & Marketing, Kevin Hayes, announced a complete series of new base receptacles offered by Alto Aviation. All are fully compatible with the company’s Articulating Arm Tablet Holder.

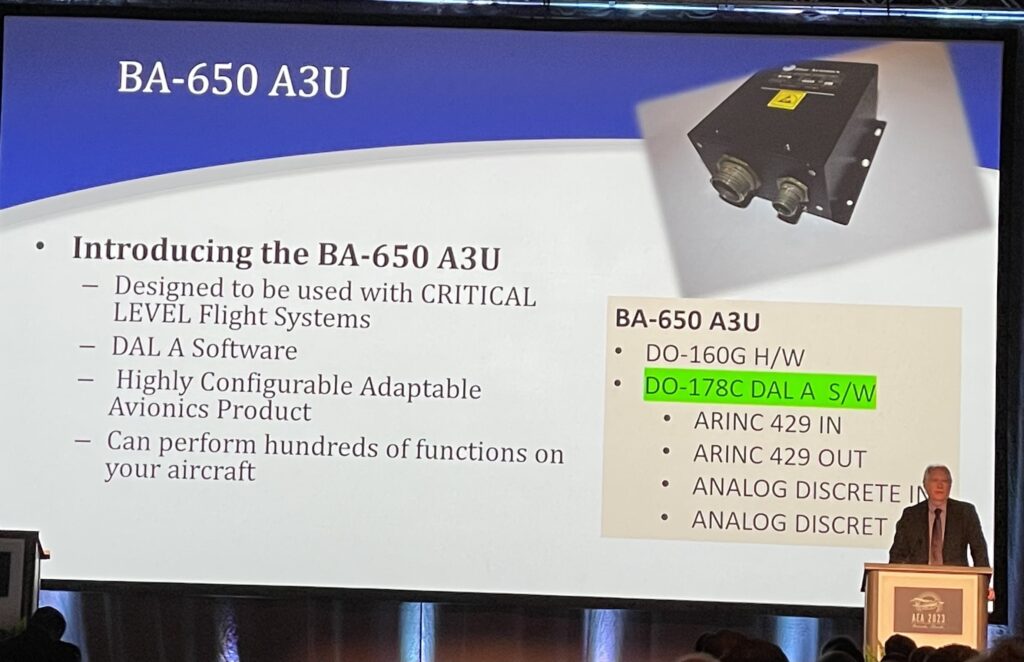

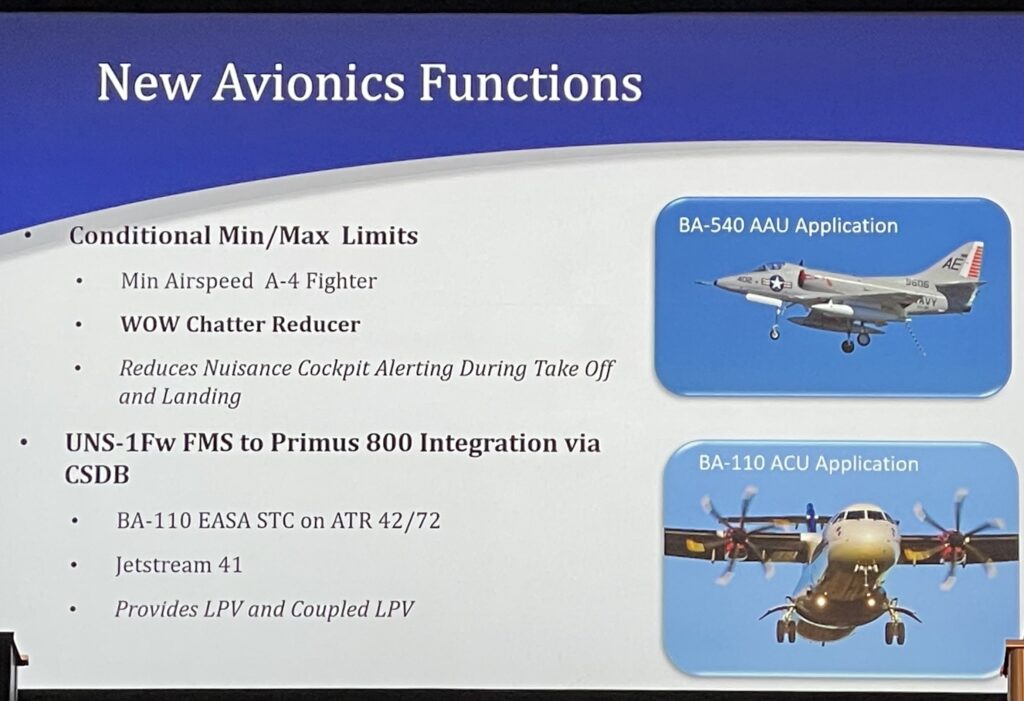

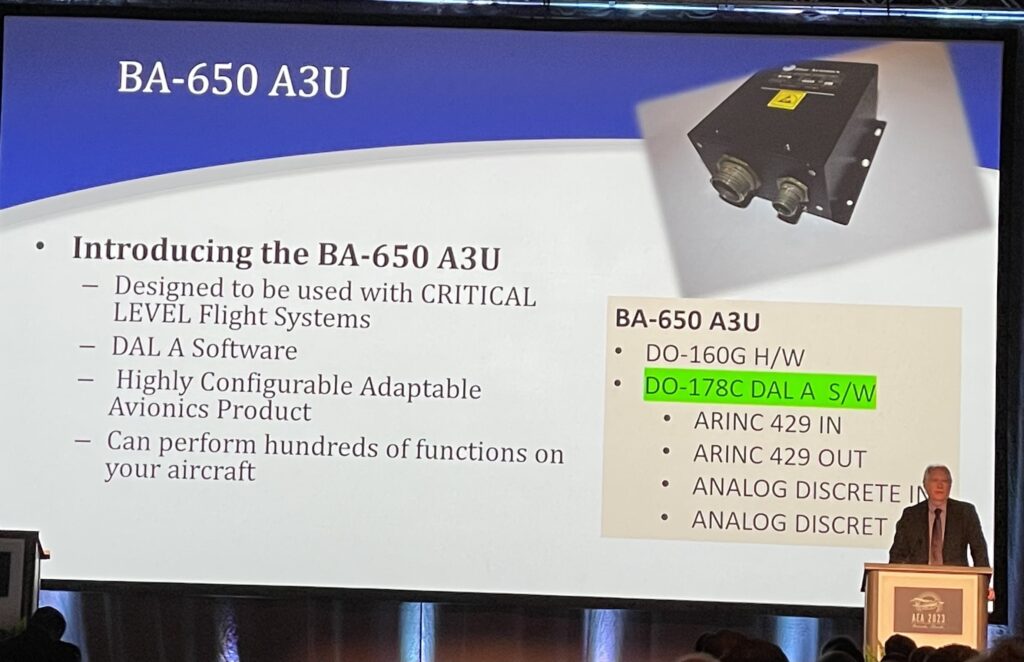

Blue Avionics

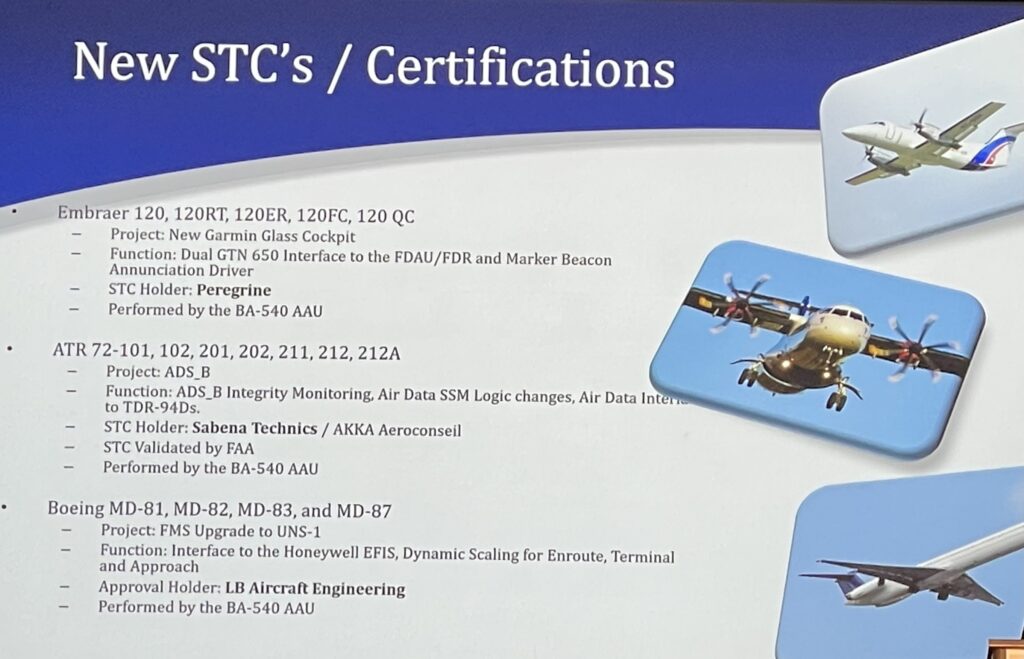

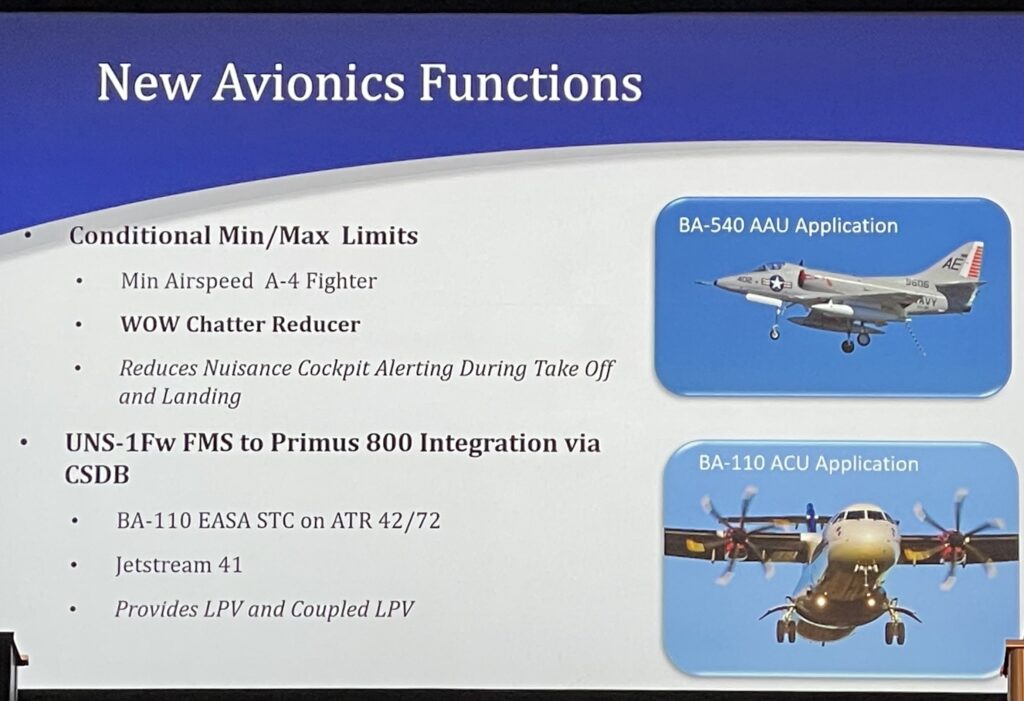

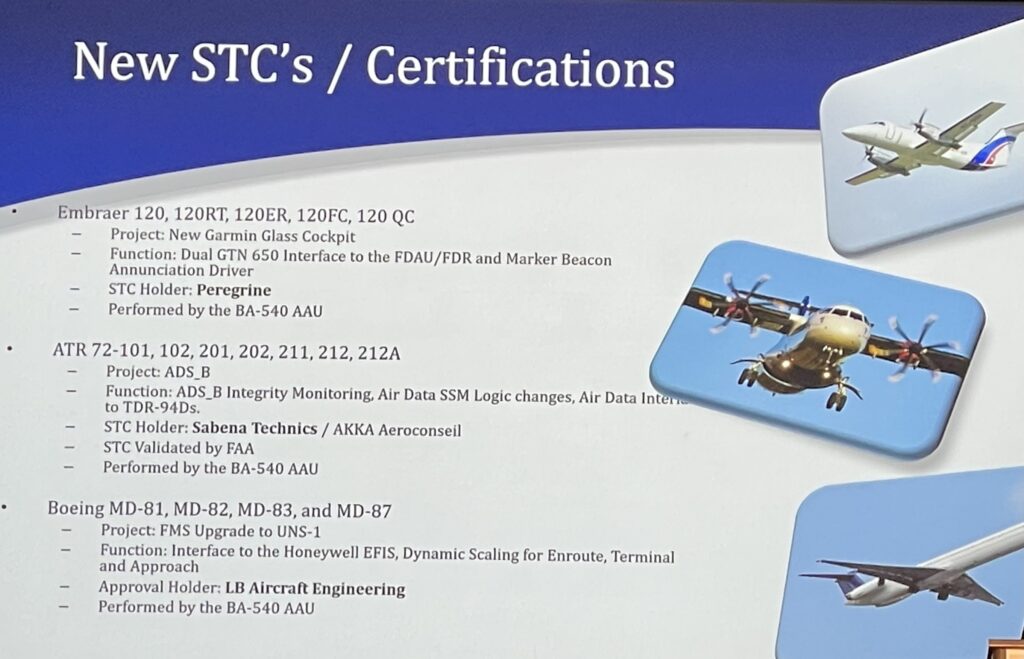

Blue Avionics designs and manufactures certified adaptable avionics products and systems. The company introduced the BA-650 A3U during the New Product Introductions at AEA.

Blue Avionics also announced several new STCs/certifications, along with new avionics functions. The company hinted at two new products that are in development now—keep an eye out for further details.

Garmin

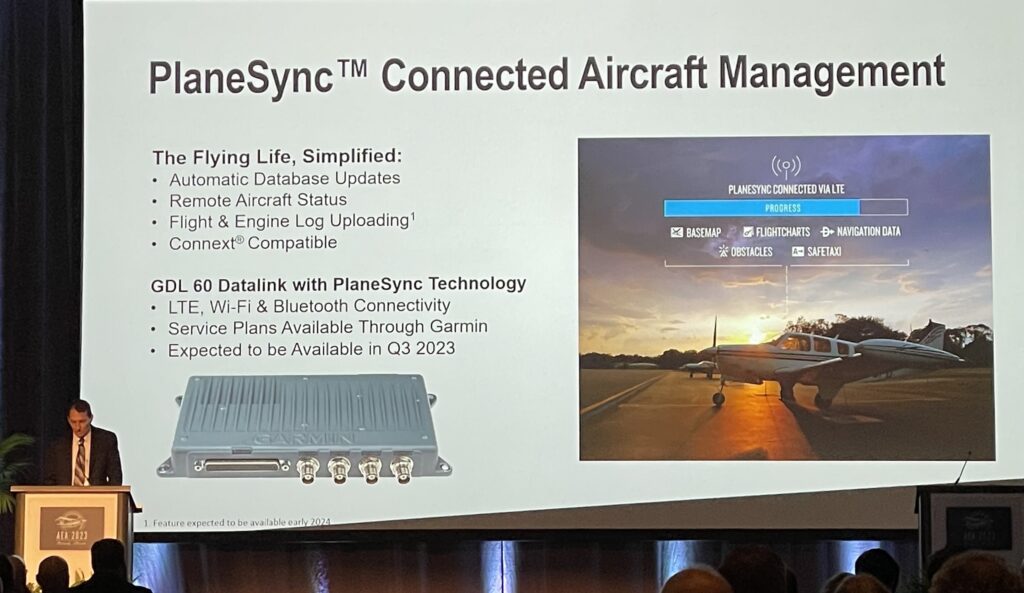

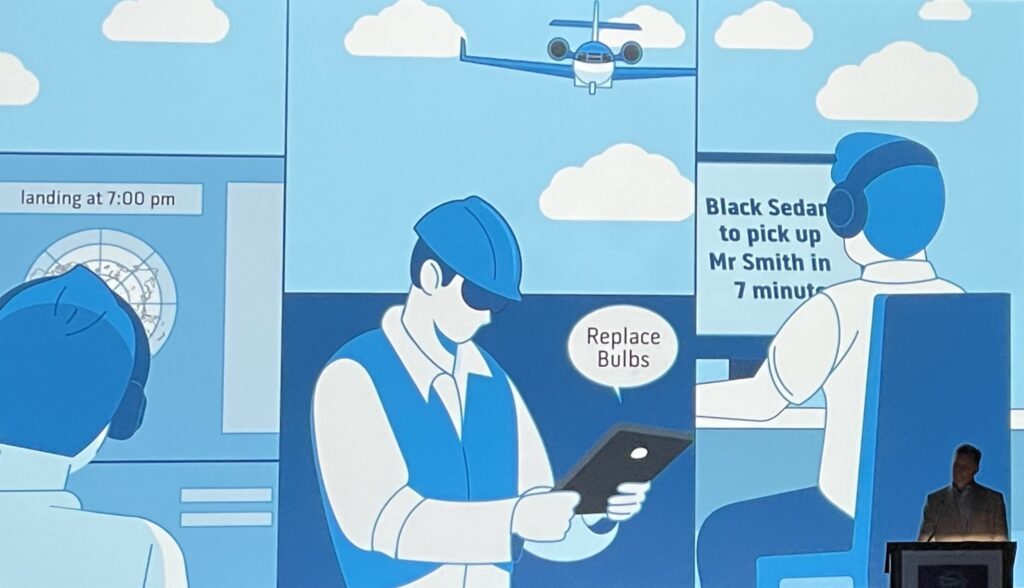

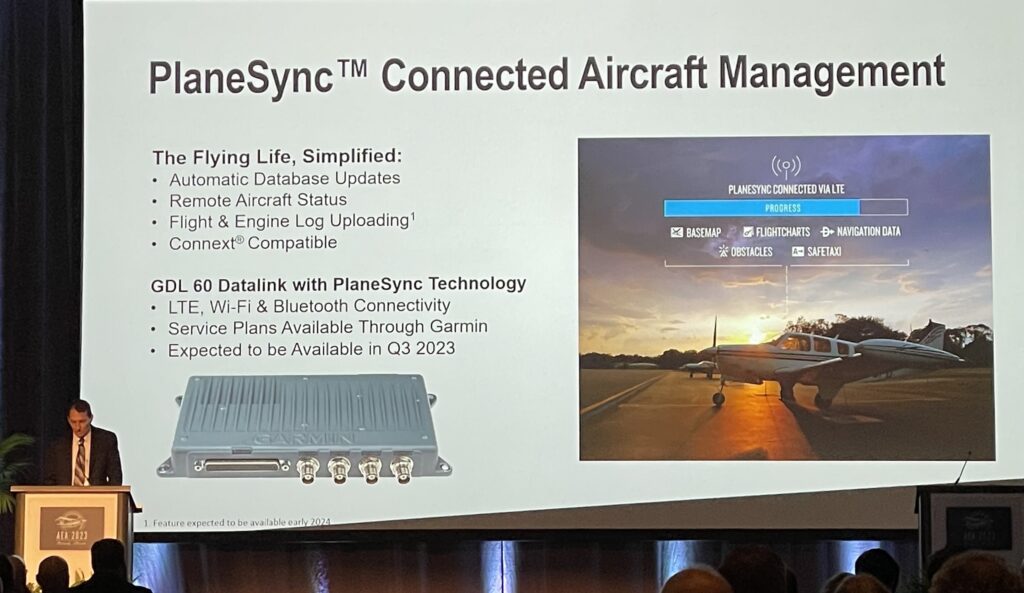

Garmin introduced PlaneSync Connected Aircraft Management and the GDL 60 Datalink with PlaneSync technology, which is expected to be available in the third quarter of the year.

With Garmin’s pilot application, users can see in the app if their plane has been serviced before heading to the airport. It streamlines the process of owning and operating an aircraft, and it enables customers to keep tabs on their plane from virtually anywhere.

Tel-Instrument Electronics Corp. (TIC)

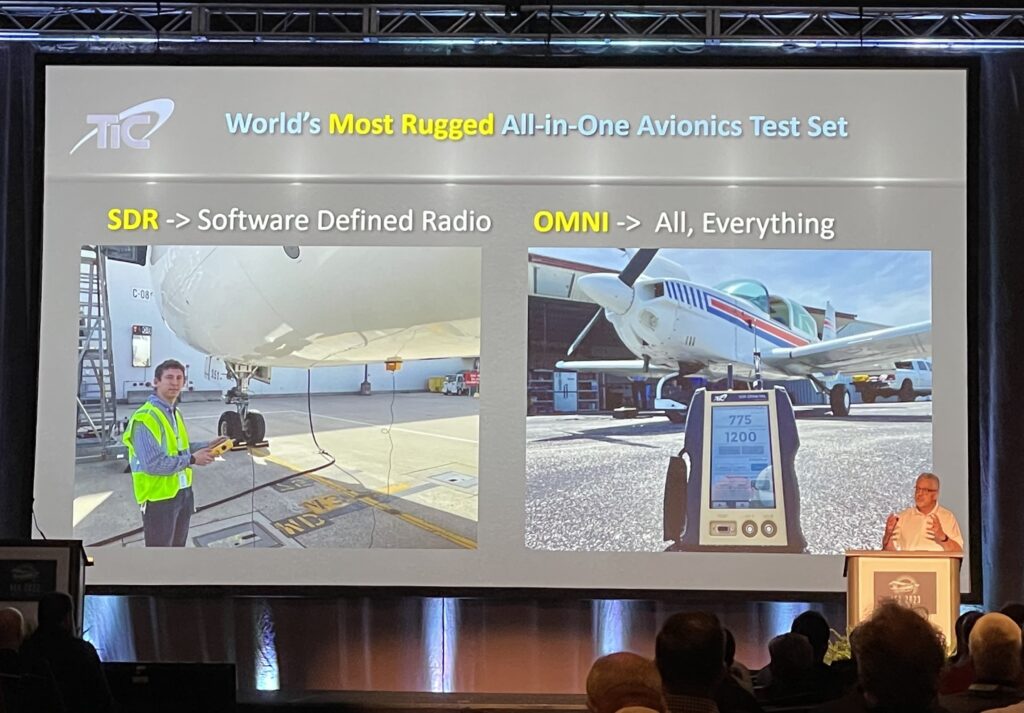

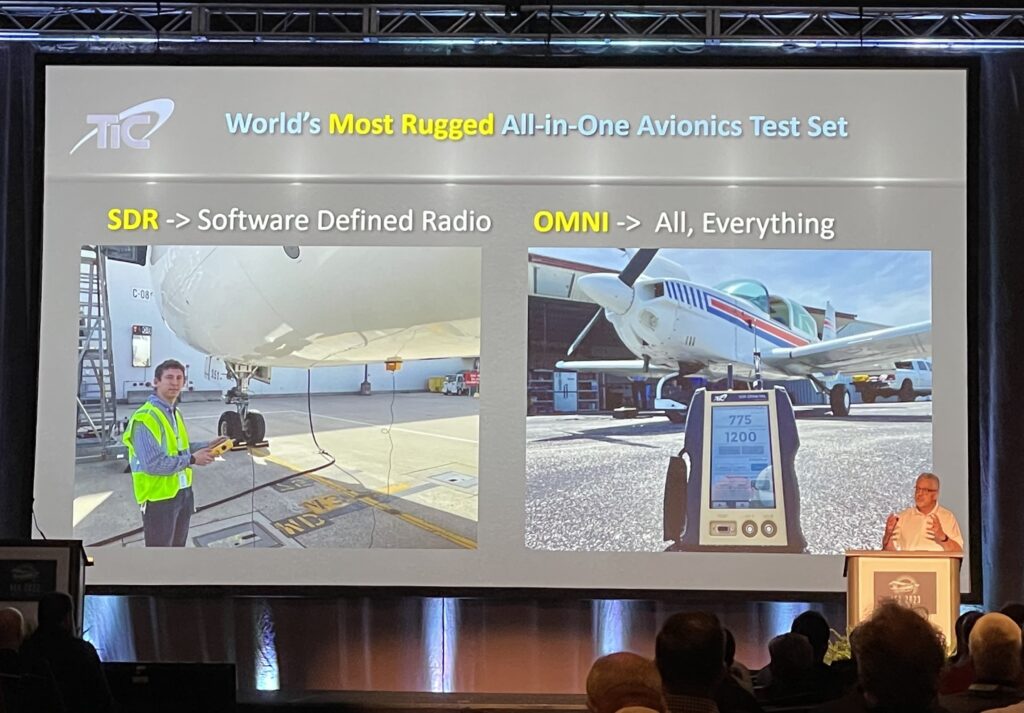

TIC develops and produces rugged avionic flight line and bench test sets. At the AEA Convention, the company introduced the SDR-OMNI, an all-in-one avionics test set. Its capabilities include surveillance systems (transponders, ADS-B In and Out, FIS-B Weather, and ACAS/TCAS); comm/emergency radios (VHF/UHF radios, HF radios, SELCAL); navigation systems (VOR and ILS, DME, GPS); and antenna/cable testing (VSWR, Distance to Fault, cable/connector insertion loss).

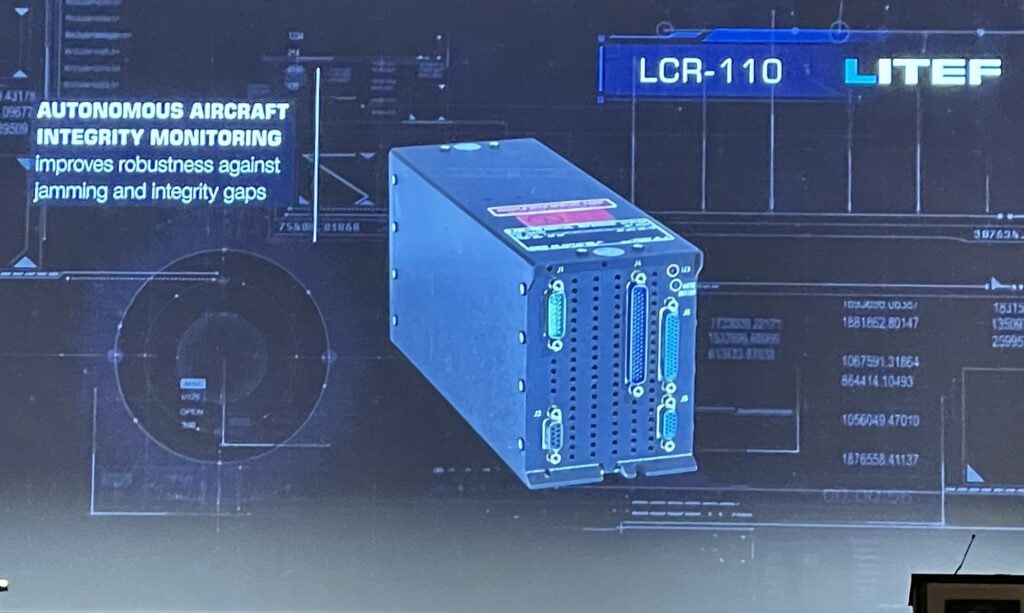

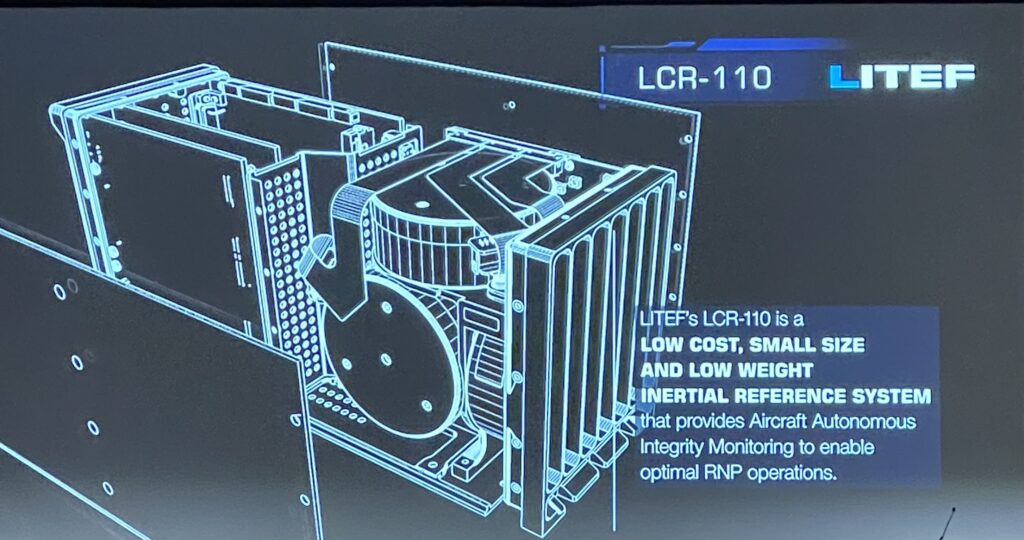

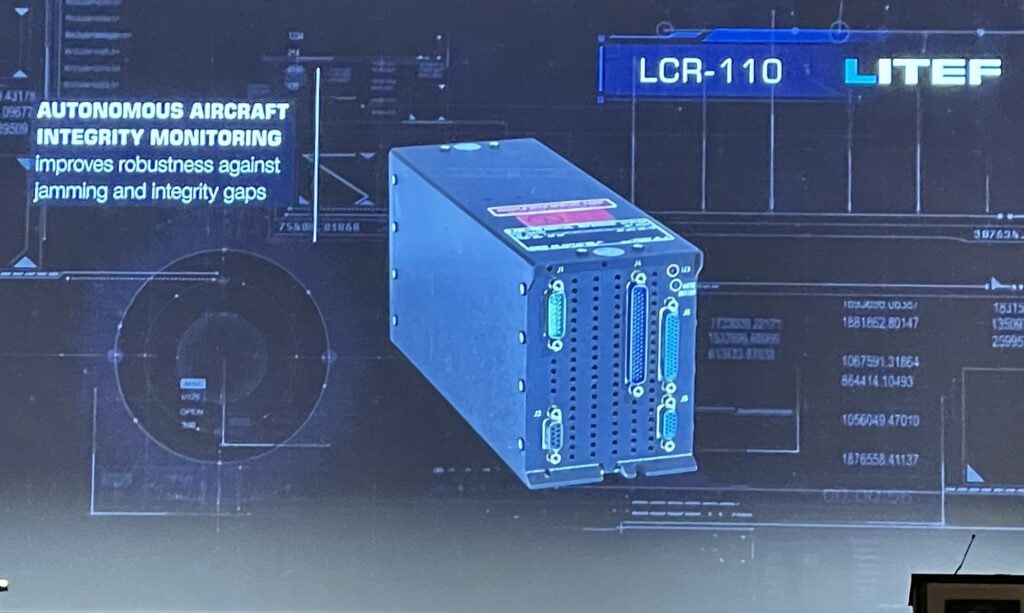

LITEF

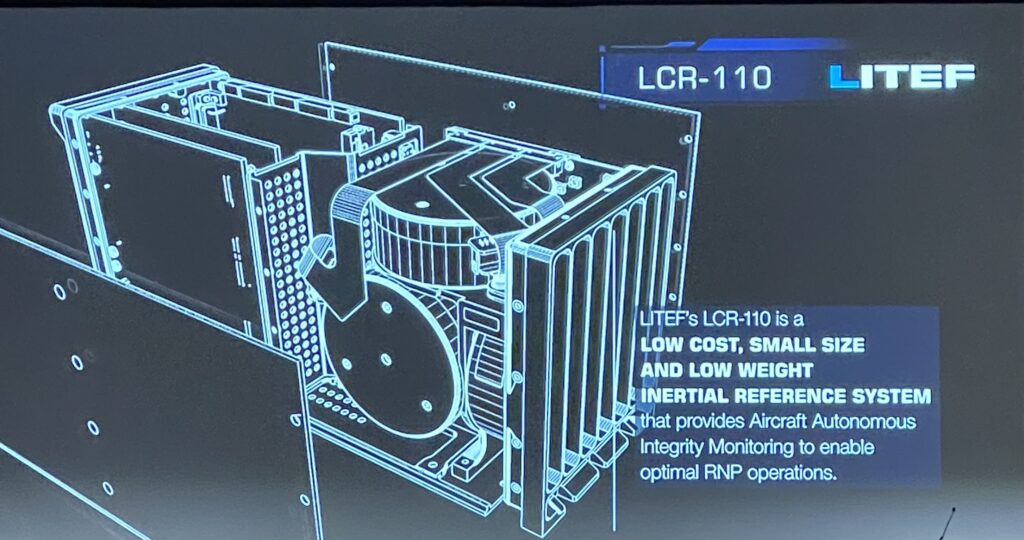

Northrop Grumman subsidiary LITEF develops and manufactures navigation and sensor systems. The company showcased the LCR-110, a small inertial reference system. It is designed as an alternative to classic IRS/INS, and it facilitates more reliable NextGen and SESAR operations of aircraft that do not have IRS/INS because of weight or costs.

Texas Aerospace Technologies

Texas Aerospace Technologies supplies next-generation and advanced avionics products to enhance flight safety through distribution and certification. The company has partnered with Curtiss-Wright, LITEF, Teledyne Controls, Genesys Aerosystems, AEM, and other leading OEMs. “The magnetic variation table to convert true heading into magnetic heading is hosted in the Installation Data Module, allowing a Mag Variation update in the field without a software update of the IRU,” Texas Aerospace Technologies shared.

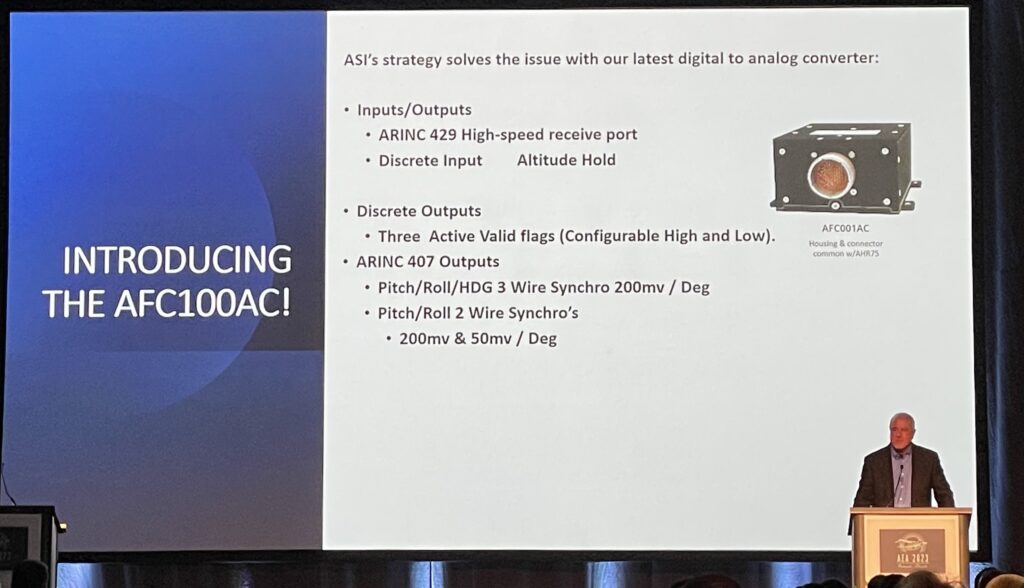

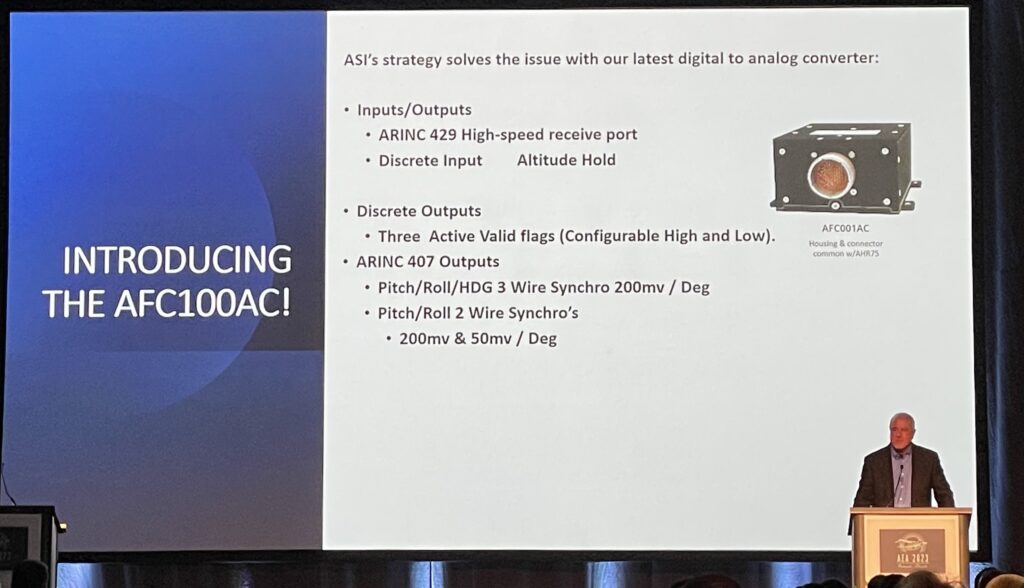

Archangel Systems

Dan Reida, director of sales, introduced the AFC100AC—the company’s latest digital to analog converter. The AFC line was designed to bridge the gap between ADAHRS and ATI instruments, and it enables efficient automatic flight control. The AFC001 model was developed to support the company’s TSO-approved Air Data Attitude Heading Reference Systems (ADAHRS) for use with analog flight control systems.

Jupiter Avionics

Bryan Hart, Sales/Marketing Director at Jupiter Avionics, introduced 12 new products at the AEA Convention this week. These included the JA72-510/610—a dual USB-C glove box with optional Bluetooth—and the JA74-510/610, a dual USB-C charger with optional Bluetooth as well. Other new products are the dual six channel mixing amplifier, JA94-R62A; the power converter (10V to 32V input), JPC-1032; and the panel protector—JA71-PP1x—among several others.

Genesys Aerosystems

Genesys introduced the Airbus H125 Single Engine IFR Operations STC project, which is scheduled for completion by the second half of 2024. This includes the Genesys Avionics Suite, made up of dual IDU-680 EFIS displays, VHF NAV/COM aircraft digital radio, IFR helicopter autopilot, dual redundant ADAHRS, dual GPS/FMS, and other equipment that is required to achieve IFR certification.

The Genesys IFR helicopter autopilot has a new 4-axis functionality. Genesys also announced its UHF Airborne Radio for fixed-wing and helicopter platforms.

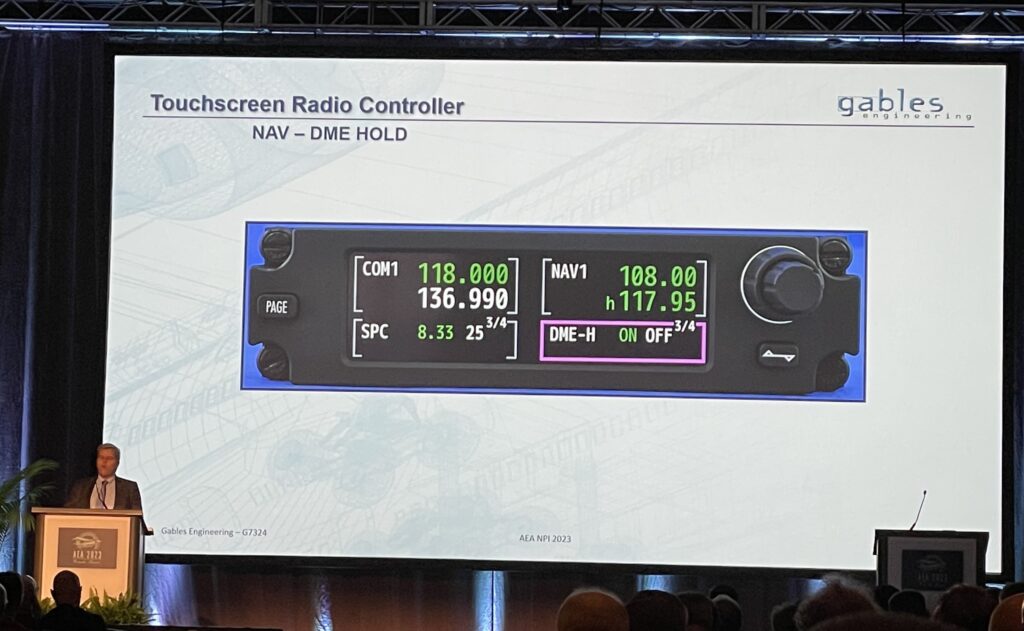

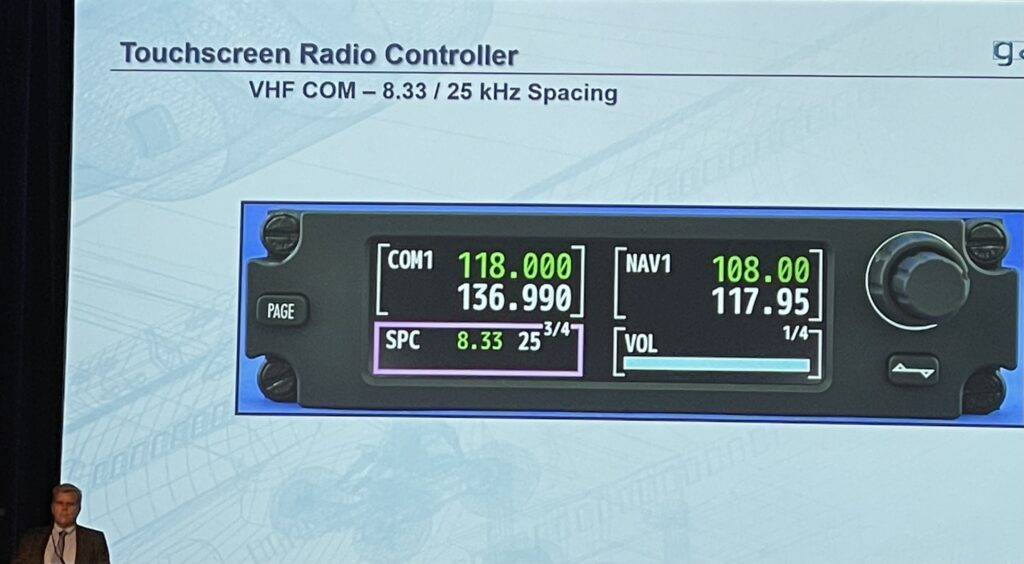

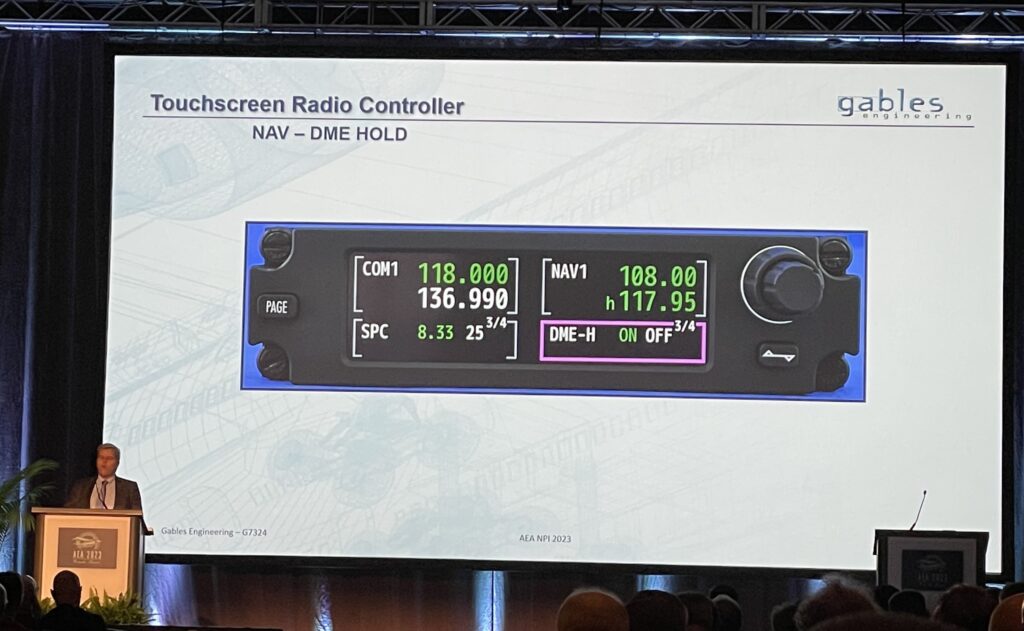

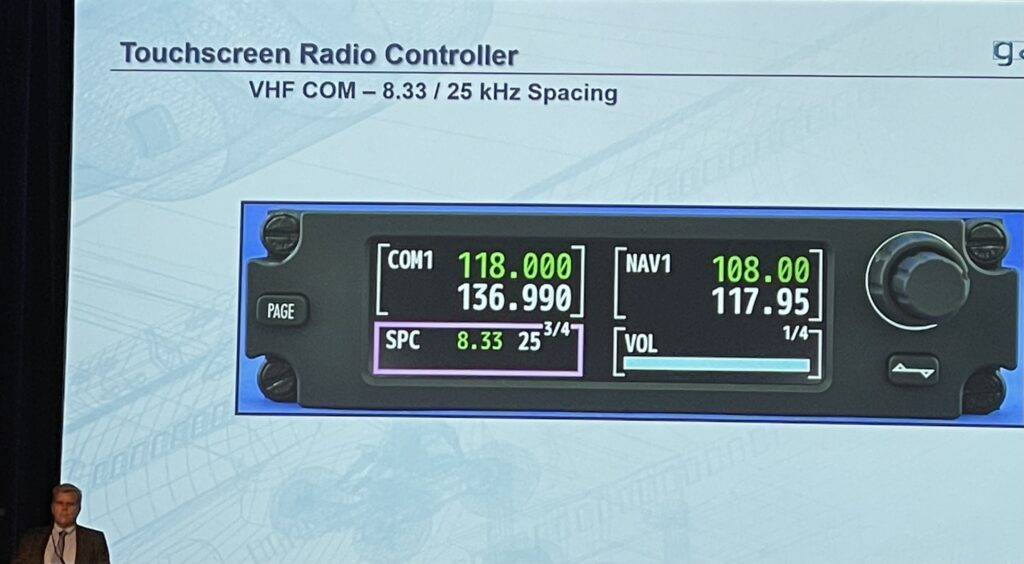

Gables Engineering

Gables showcased its G7324 touchscreen radio controller for Genesys Aerosystems’ digital radio series. Rick Finale, SVP Engineering & Business Development, shared details of the controller’s dimensions (1.485″ x 5.735″ x 0.376″) and electrical requirements (power 28 VDC, 10W [max]).

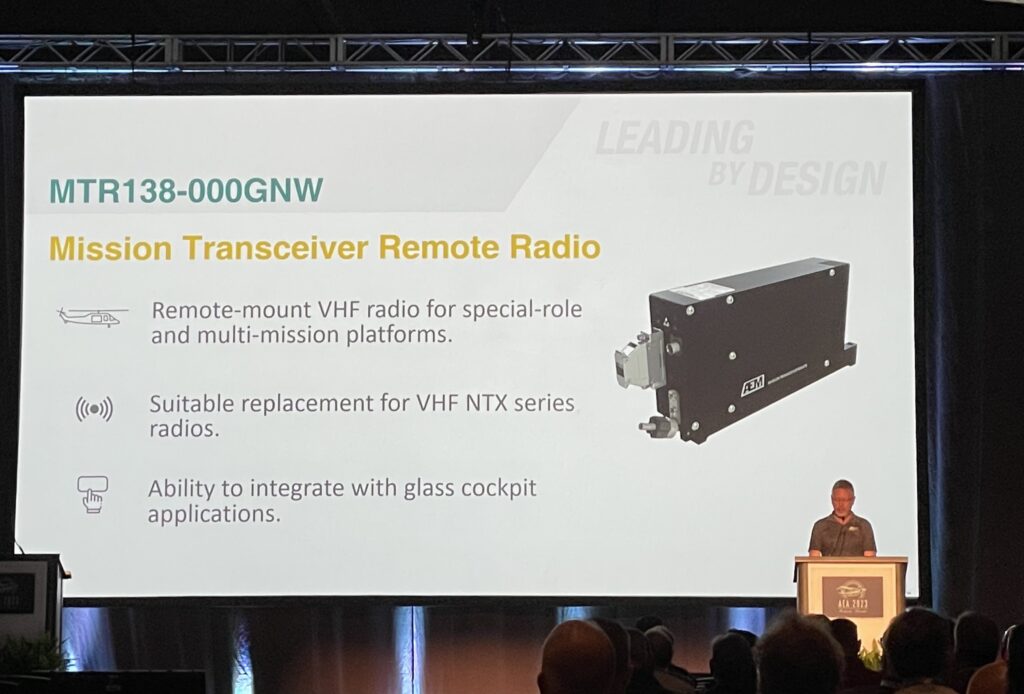

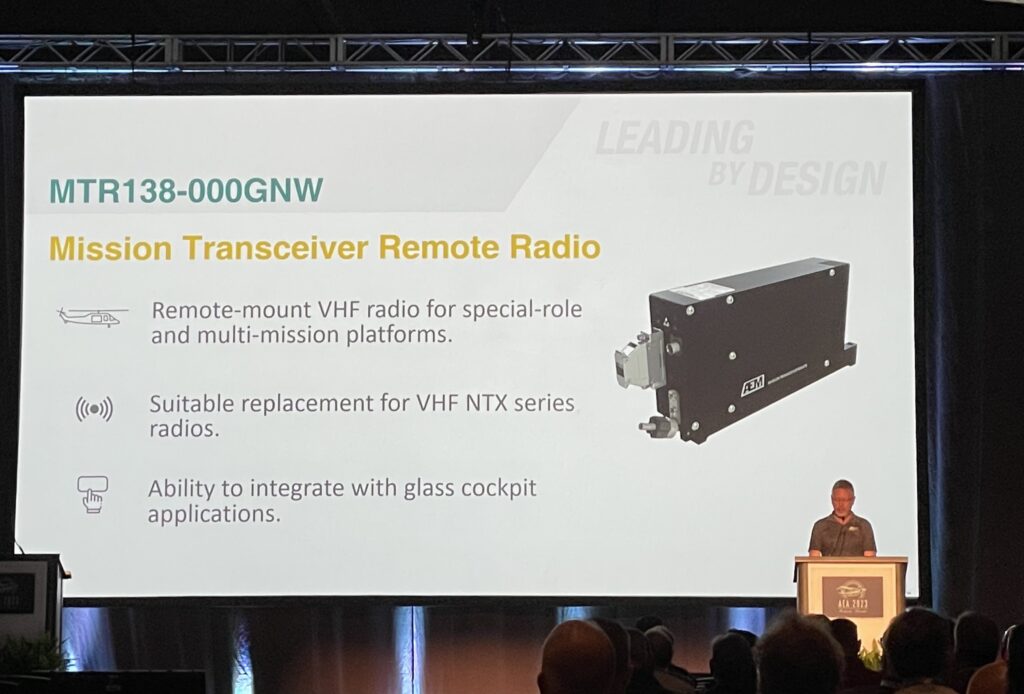

AEM (Anodyne Electronics Manufacturing Corp.)

Steve Broderick of AEM introduced the MTR138-000GNW Mission Transceiver Remote Radio. Some of its advantages include a narrowband/wideband remote-mount transceiver; its coverage of a frequency band from 138MHz to 174MHx; and its ability to interface with a glass cockpit or panel-mount controller.

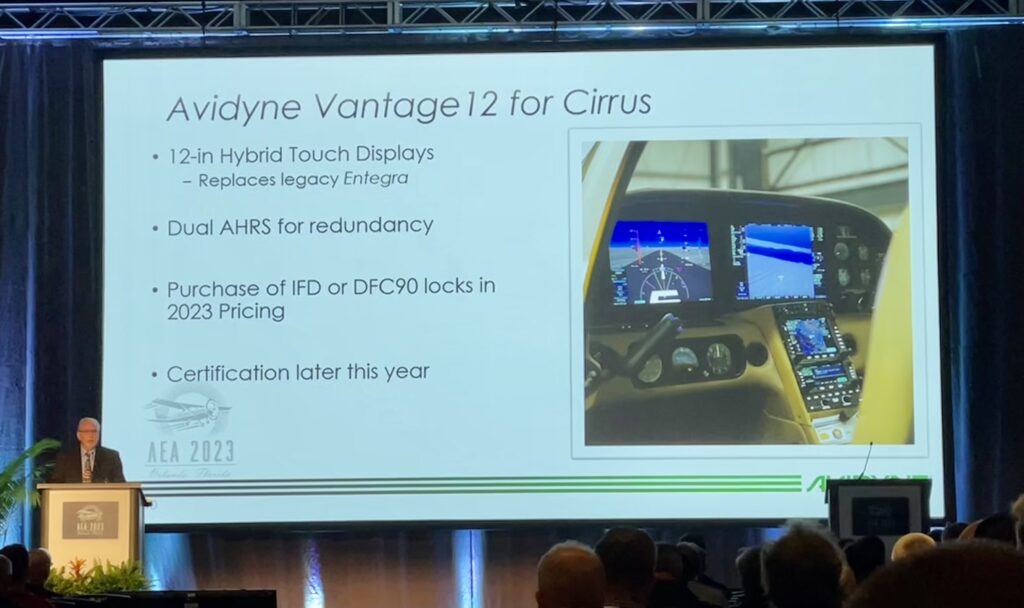

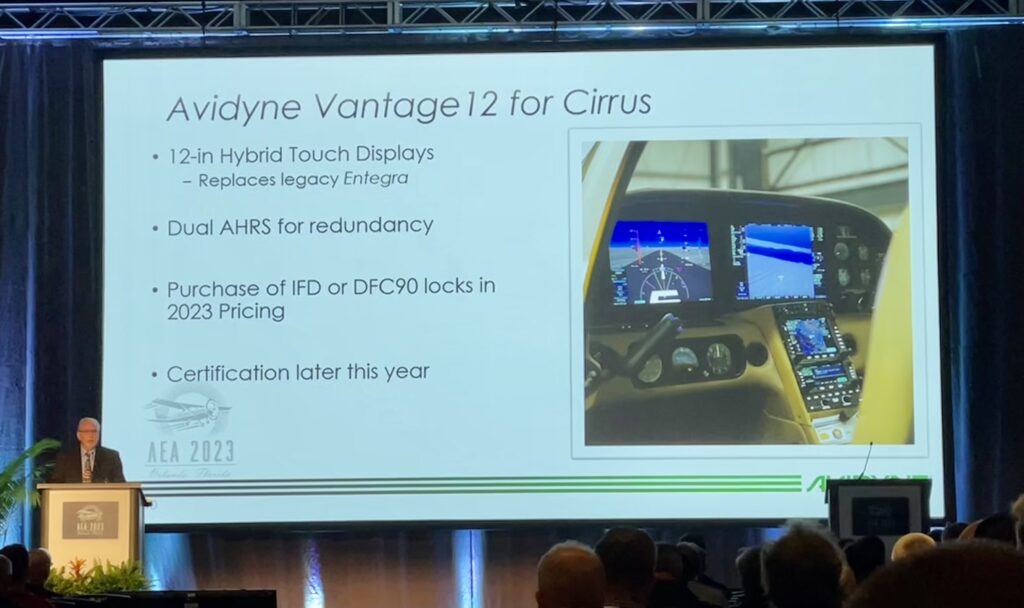

Avidyne

Tom Harper, Director of Marketing at Avidyne, shared the company’s Vantage12 upgrade for Cirrus, which includes dual AHRS for redundancy, and is expected to receive certification by the end of 2023.

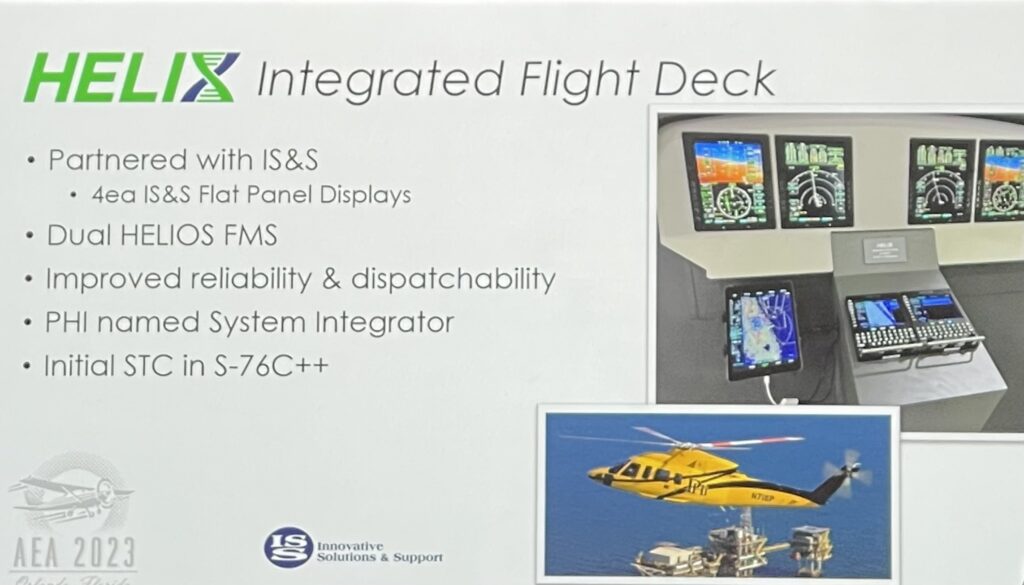

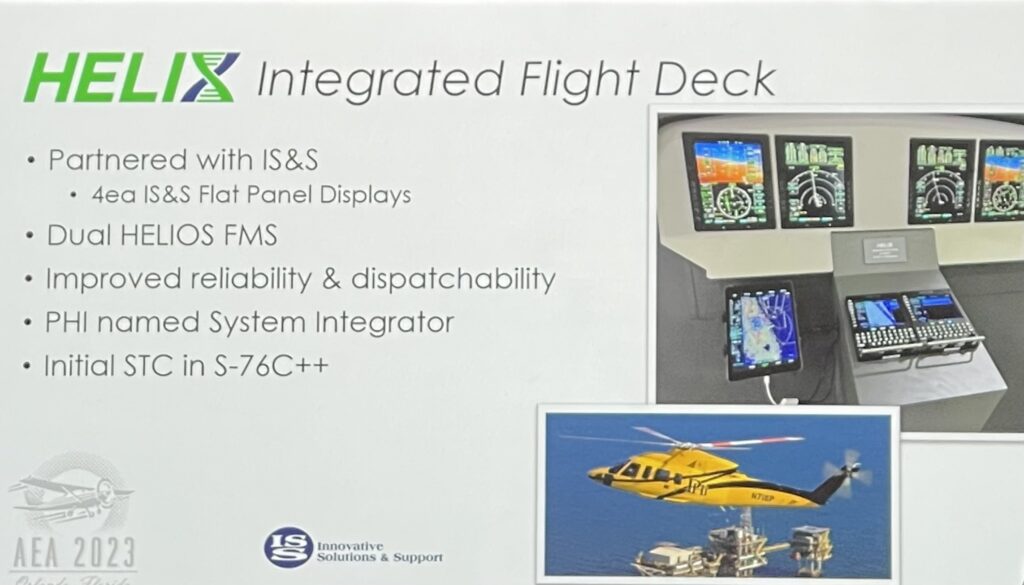

Avidyne previously announced the HELIX Integrated Flight Deck at Heli-Expo. It will be available later this year, according to Harper.

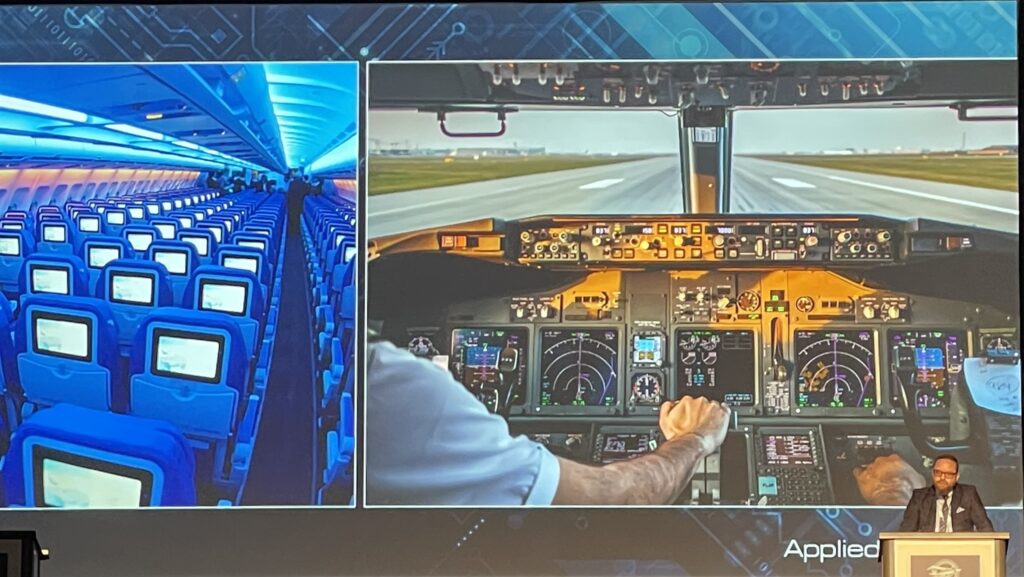

Applied Avionics

Joe Stiffler, NEXSYS Product Line Manager, announced the embedding of signal processors into the form factors they already provide. NEXYS LYNK is the company’s integrated signal processor, featuring 28 addressable I/O pins and an internal momentary switch to allow for human-machine interface.

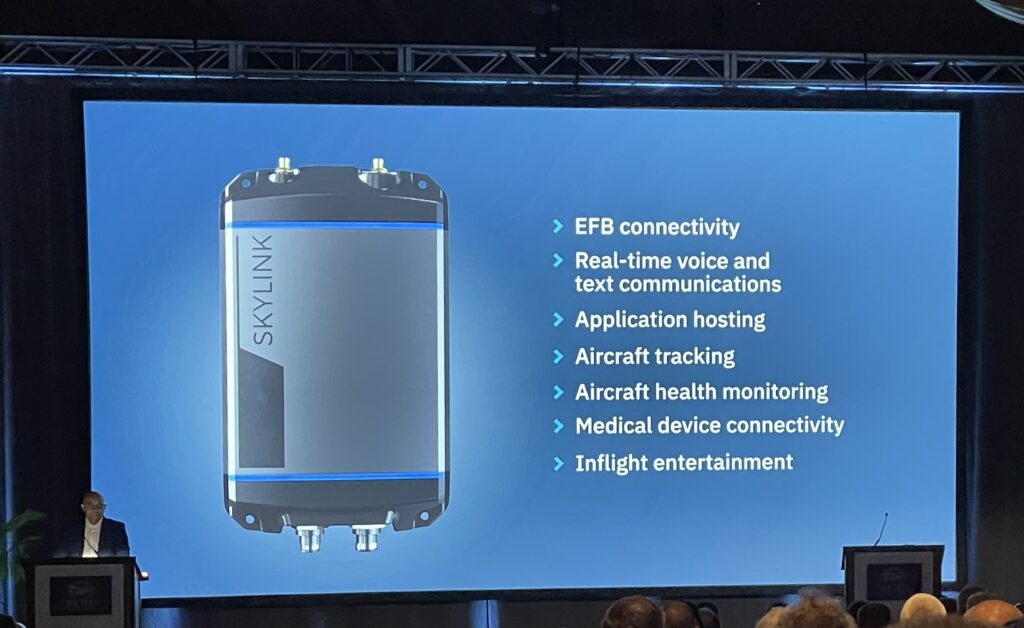

SKYTRAC

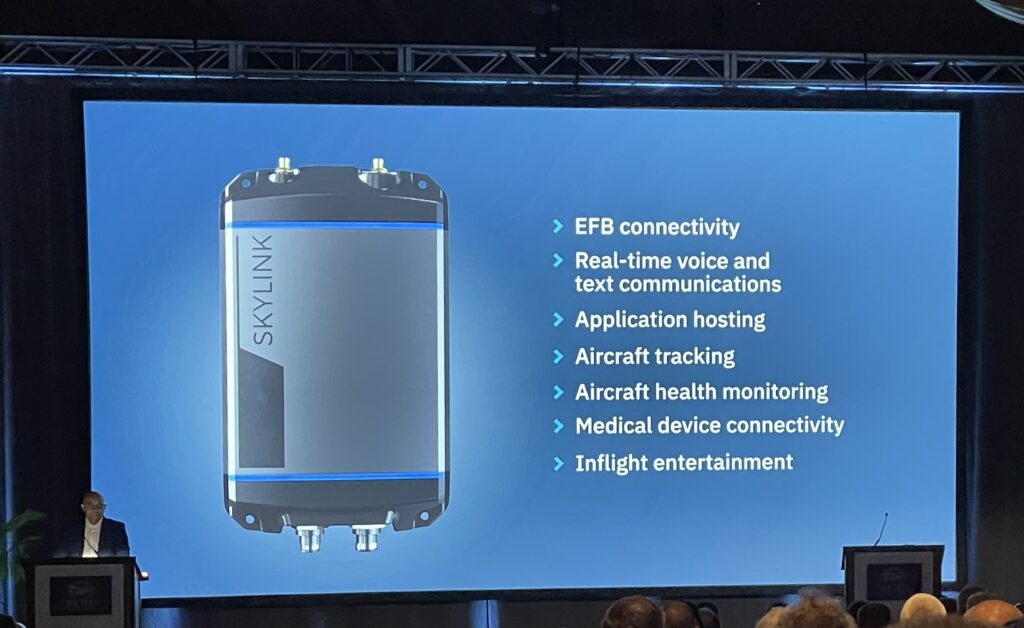

Reuben Mann, Head of Marketing at SKYTRAC, revealed the SkyLink 7100. The compact communications terminal offers 4G/LTE and Iridium Certus broadband satellite technology.

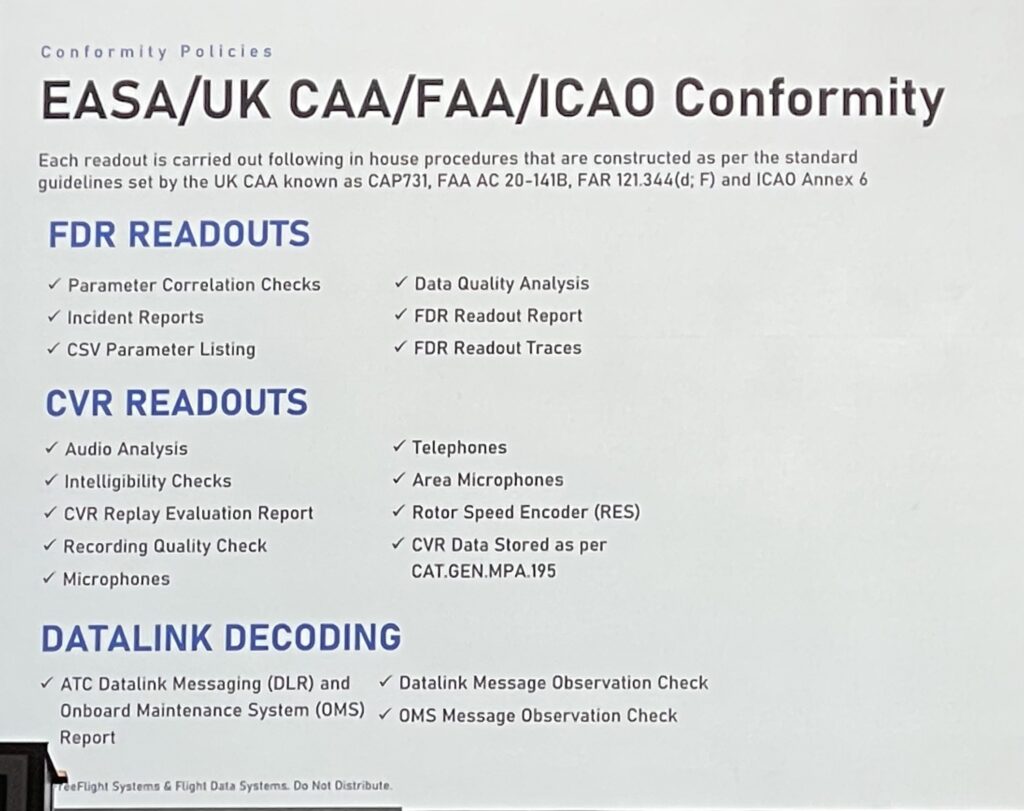

Flight Data Systems

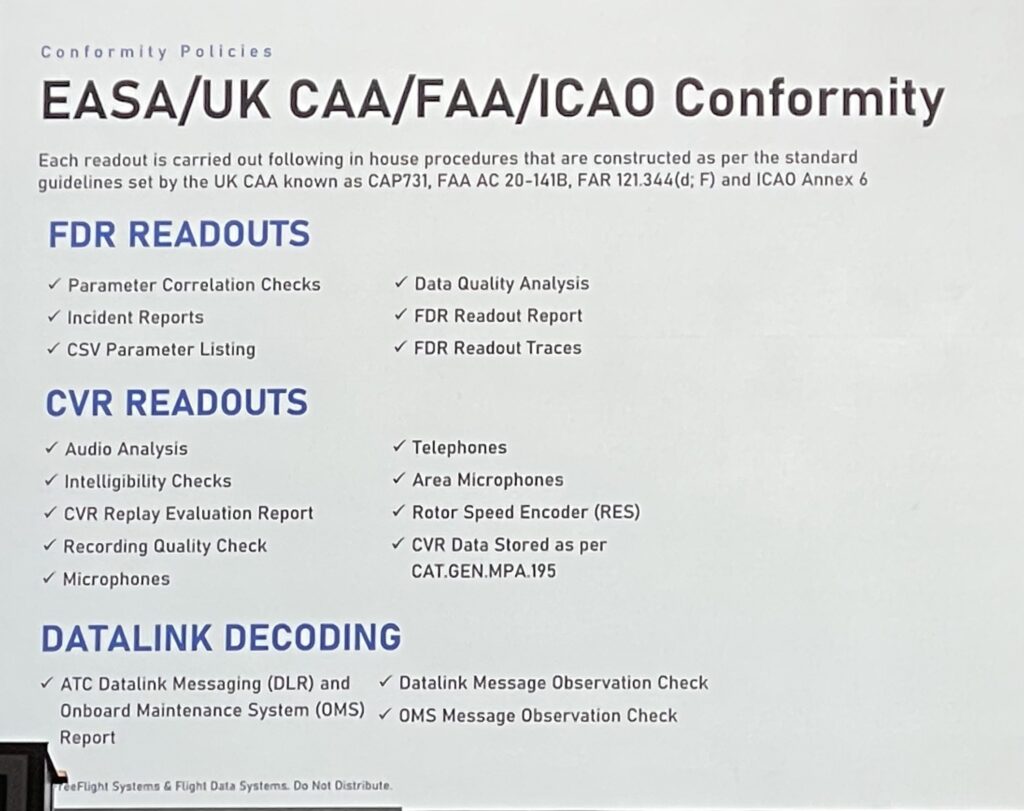

Flight Data Systems manufactures avionics and instruments. The company just announced that it has completed Approved Model List (AML) Supplemental Type Certificate (STC) for the TSO’d SENTRY Cockpit Voice Recorder (CVR) with Recorder Independent Power Supply (RIPS), SENTRY Cockpit Controller, and SENTRY Cockpit Area Microphone (CAM) by Canada West Avionics. FDS carries out readout services under EASA/UK approvals that enable customers to build the foundation of their flight data safety analysis programs. Its readout services also conform to ICAO and FAA recommendations.

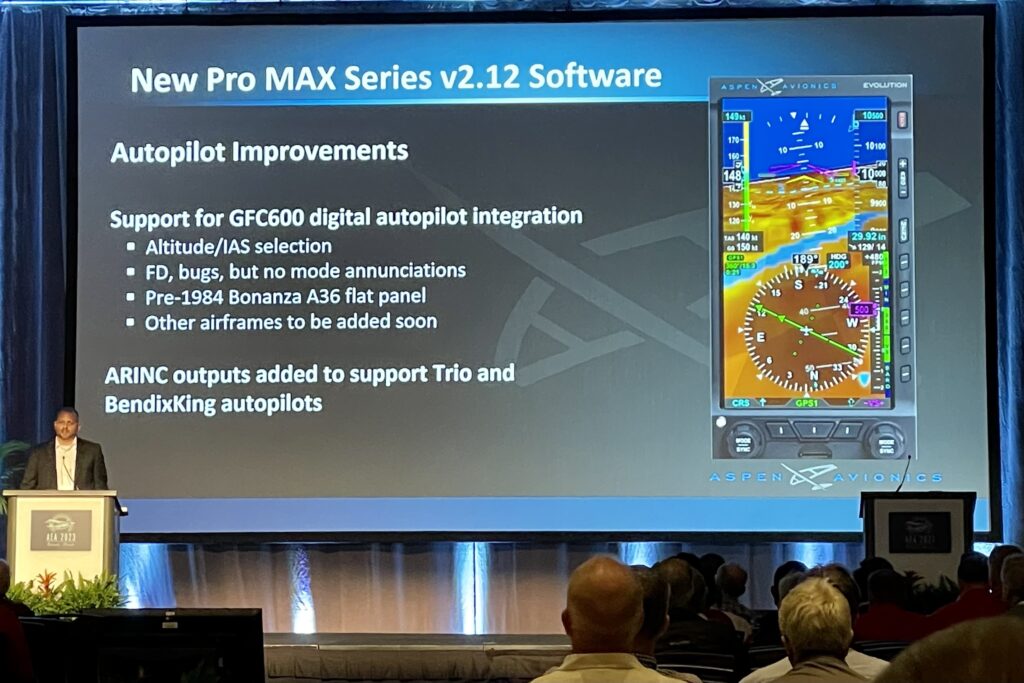

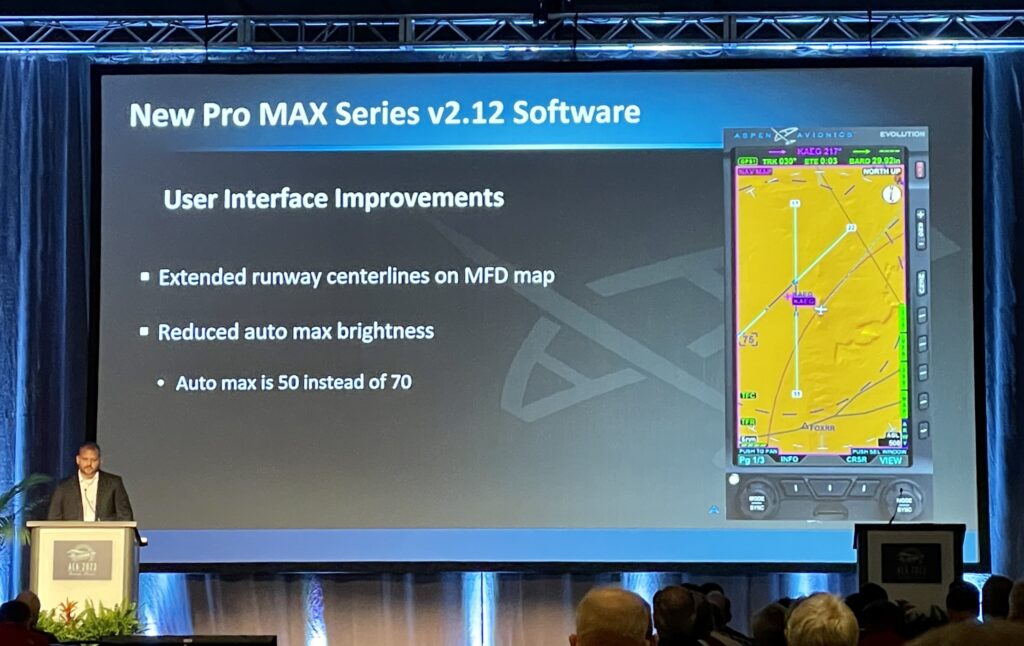

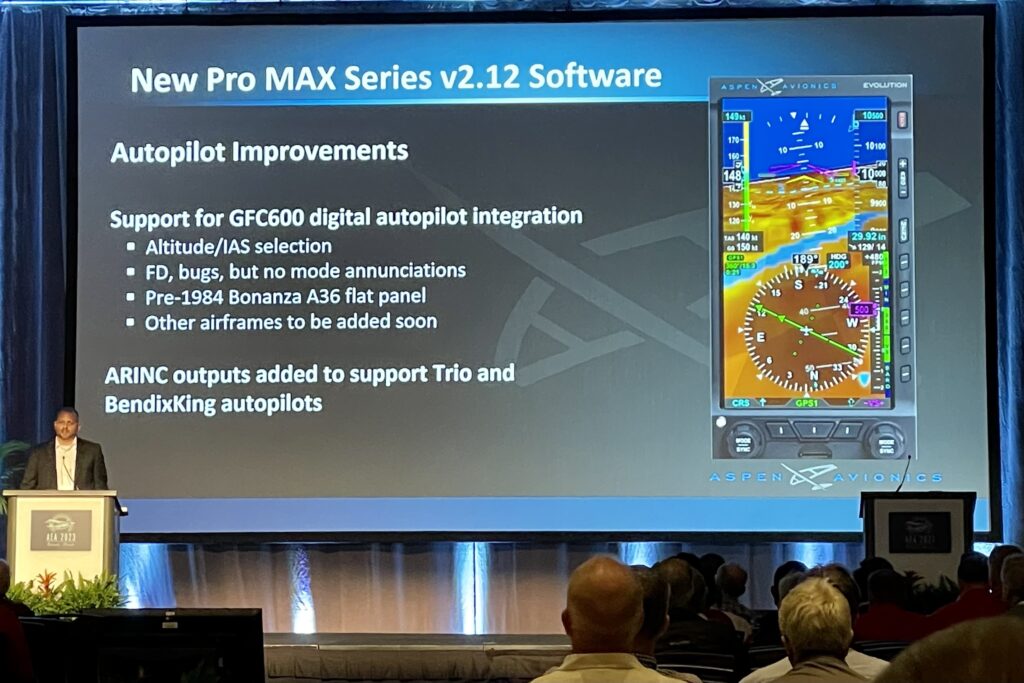

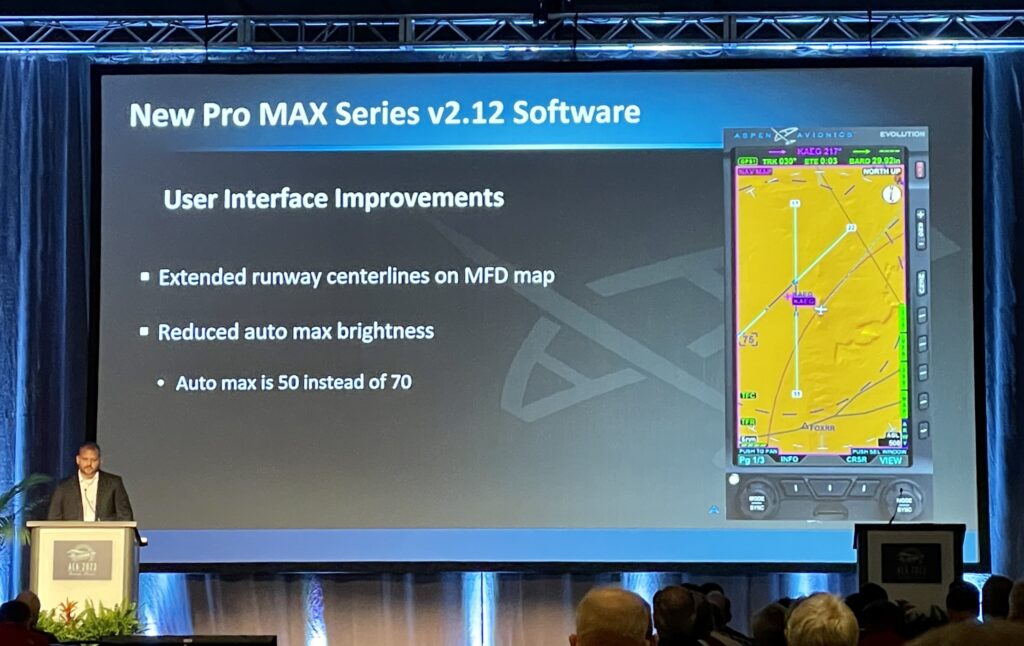

Aspen Avionics

Andy Smith introduced Aspen Avionics’ new Pro MAX Series v2.12 software, including details about improvements to autopilot integration and the user interface. Mark Ferrari commented on the new software release following FAA approval in February, saying, “Aspen’s Pro MAX PFD coupled with the Garmin GFC600 autopilot enhances and expands the basic autopilot function and streamlines the controls, reducing workload and removes the need for some external adapters. When combined with all the features and benefits of Aspen’s glass panel technology, flying becomes easier and safer, especially for single pilot IFR missions.”

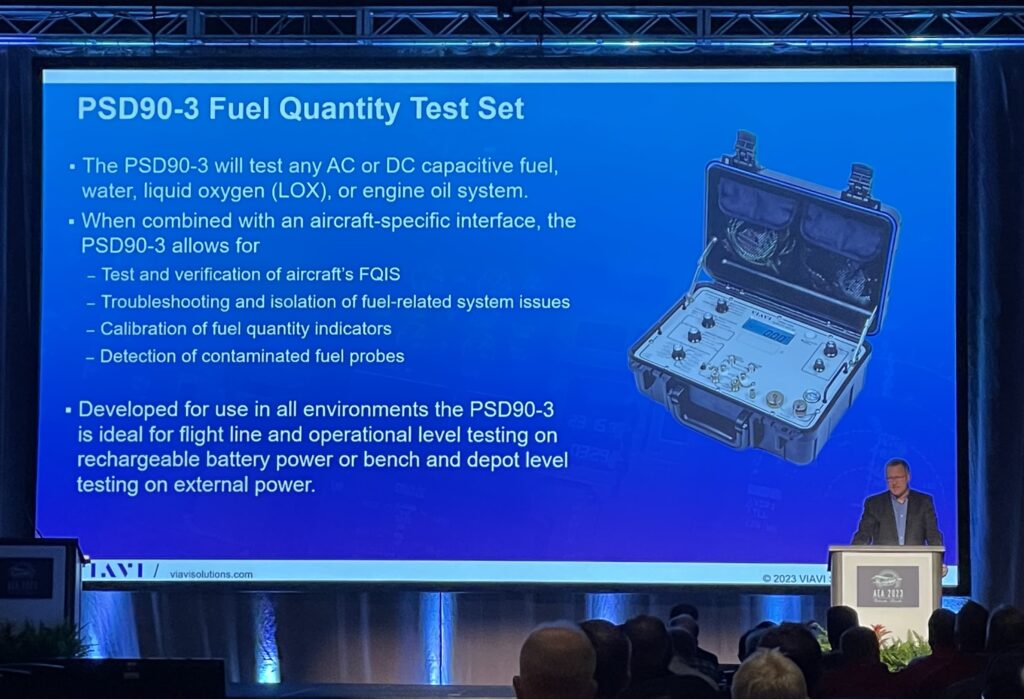

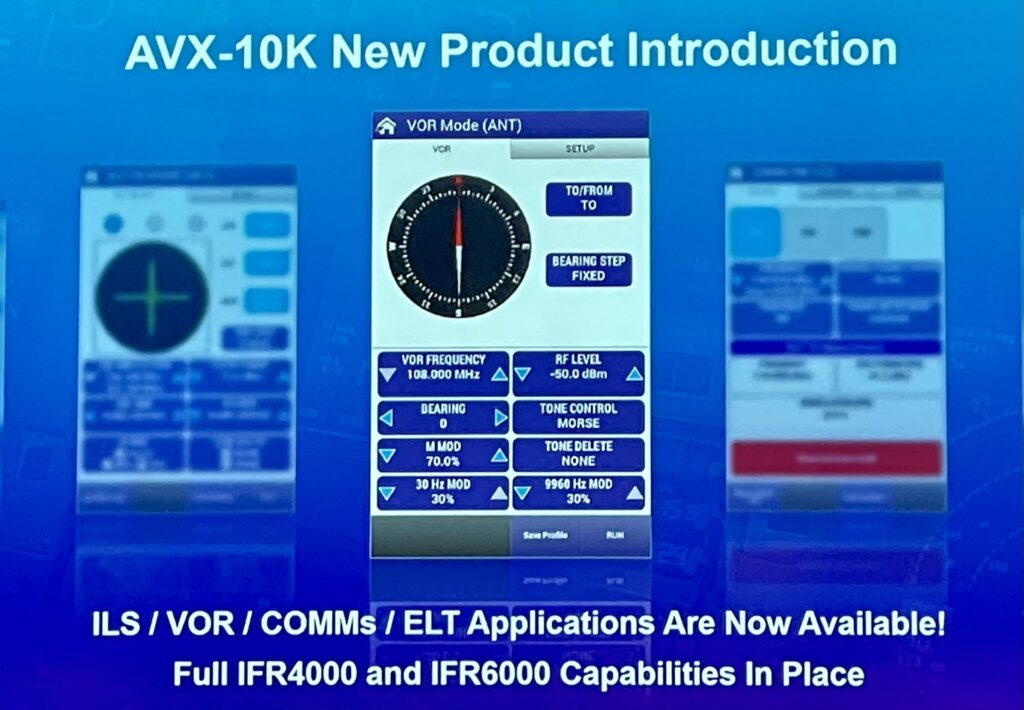

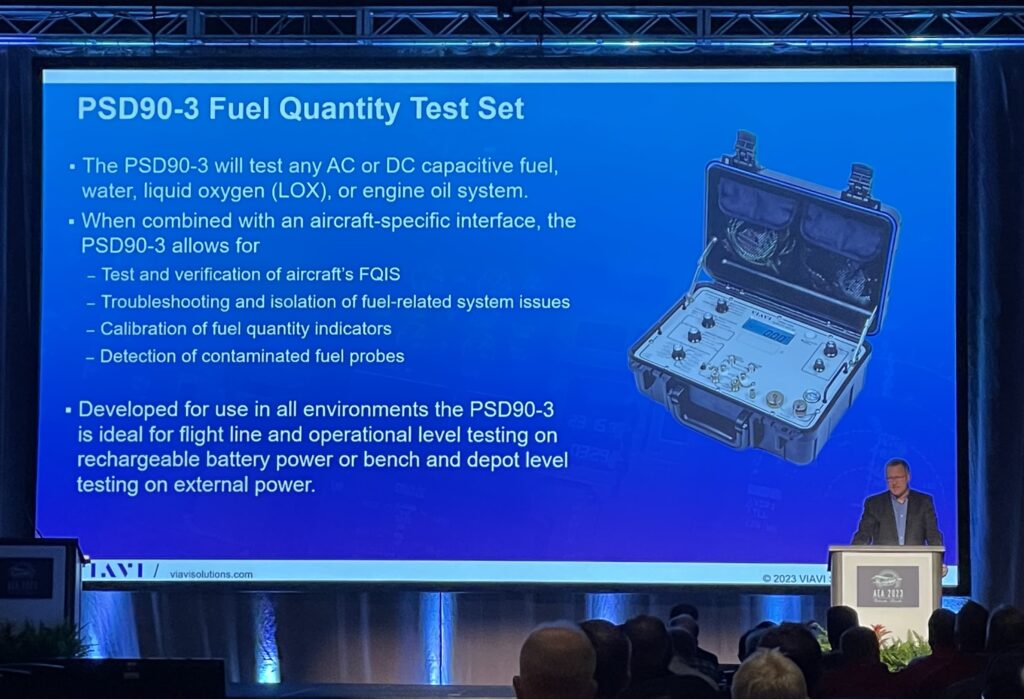

VIAVI Solutions

Mark Anderson commented that VIAVI has “2.5 product announcements” at the AEA Convention. First, the PSD90-3 Fuel Quantity Test Set was introduced. It features a new modern architecture and design, and it can replace current Fuel Quantity Test Sets as a single test solution. Users can use either Auto or Manual mode to detect and isolate contaminated fuel probes.

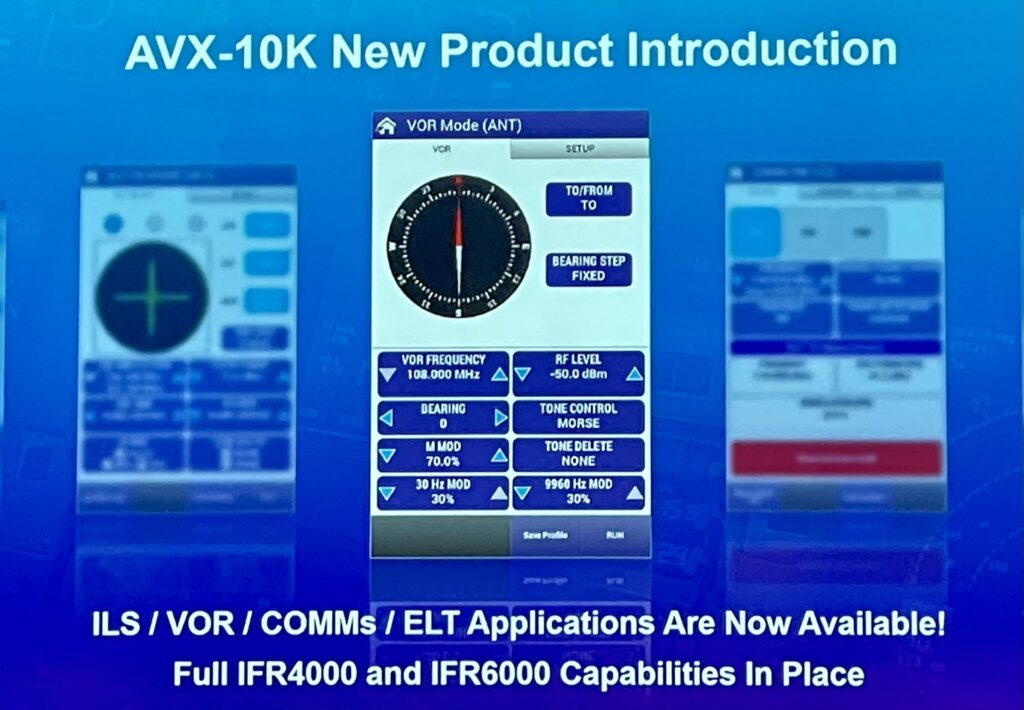

VIAVI also revealed the AVX-10K Flight Line Test Set and the UC-584 Stub Style Transponder Antenna Adaptor.

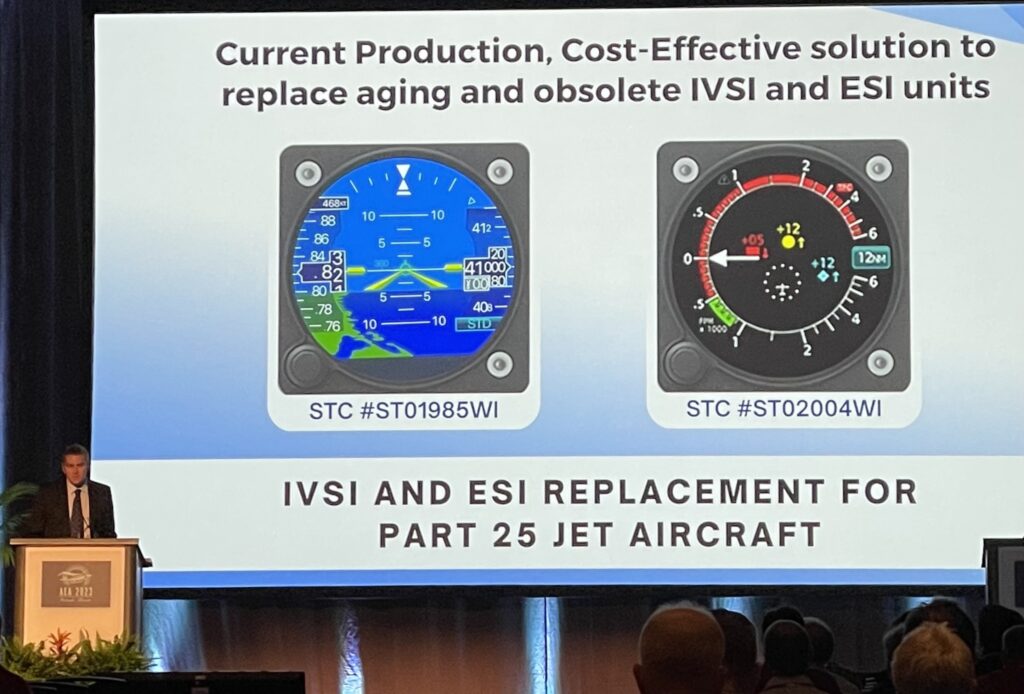

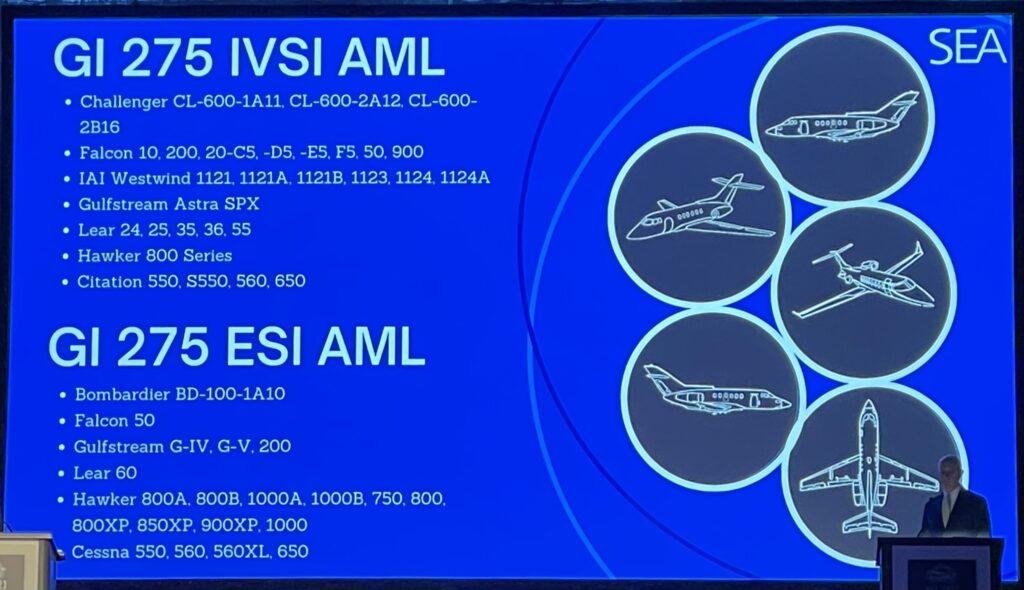

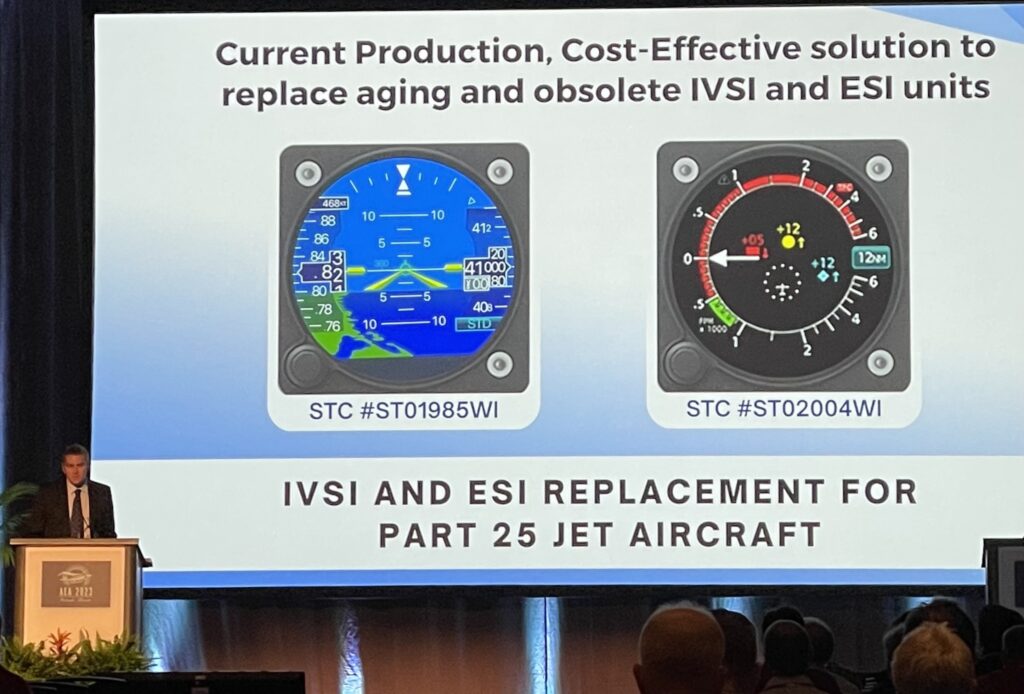

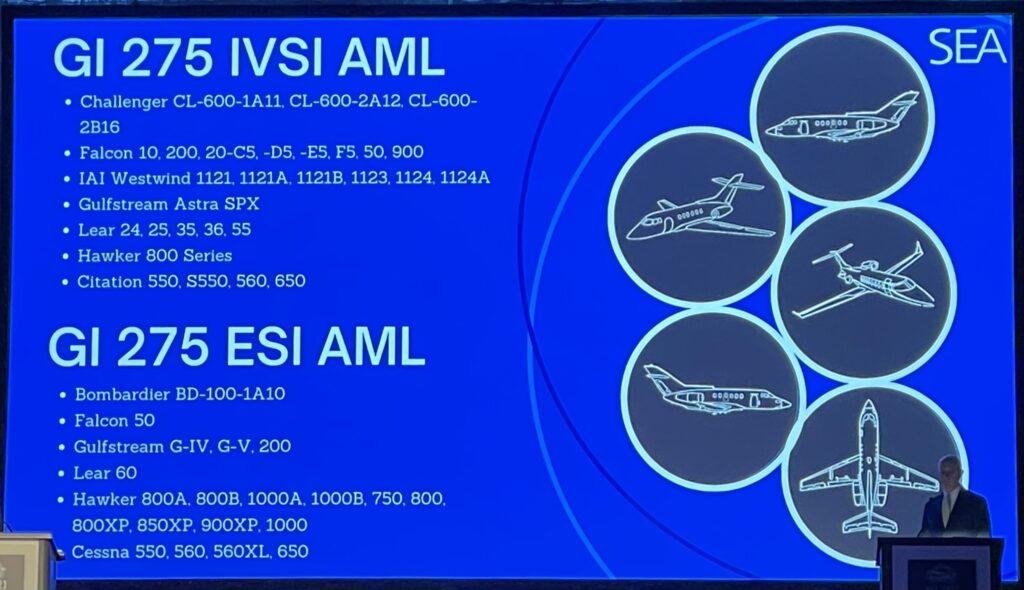

Southeast Aerospace (SEA)

Luke Gomoll, Aircraft Modification Sales Representative at Southeast Aerospace, talked about SEA’s IVSI and ESI STCs. The IVSI STC offers an alternative to expensive repairs for unreliable IVSI units and it includes integration with TCAS II and Resolution Advisories display. The ESI STC enables optional interfaces of GPS, Heading, and Navigation.

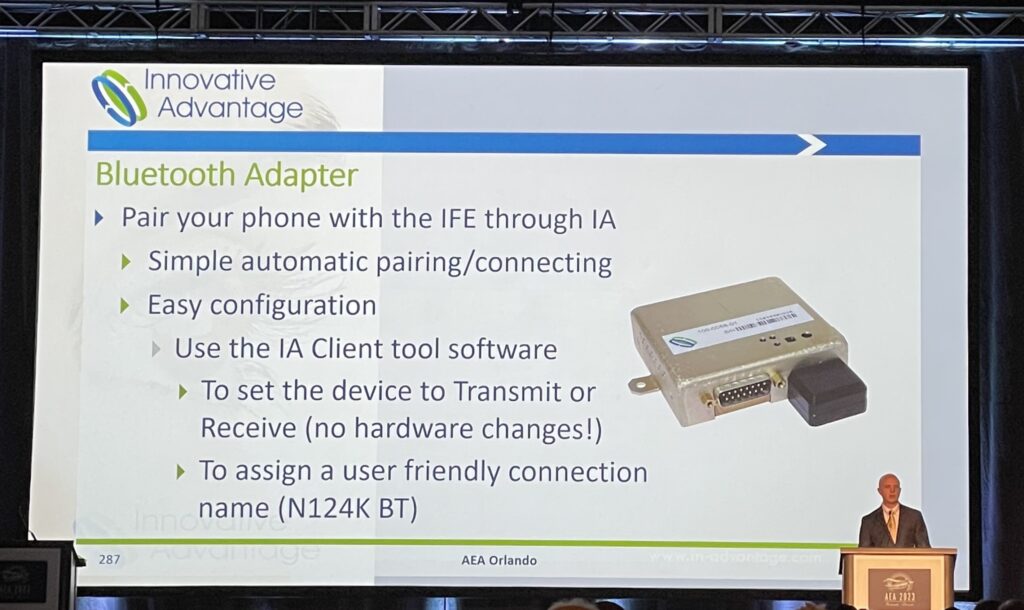

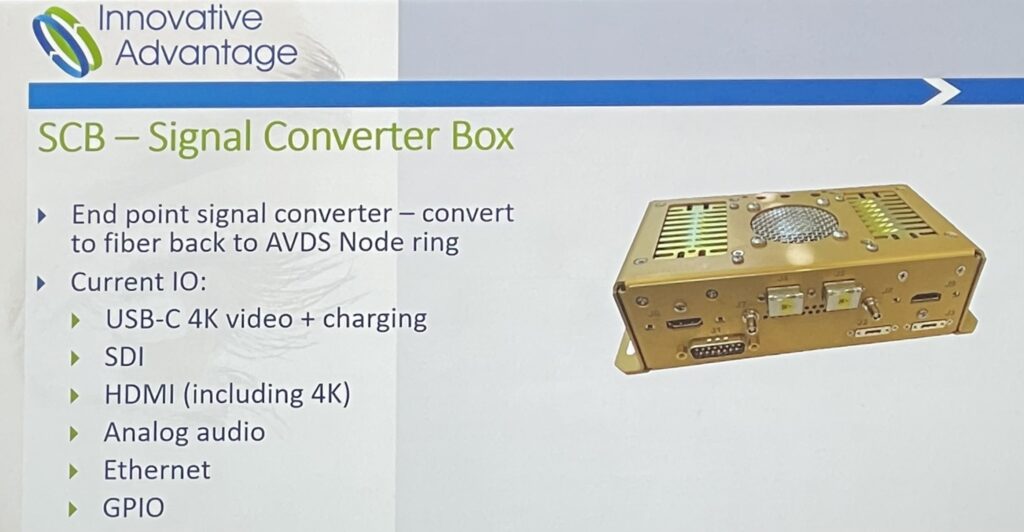

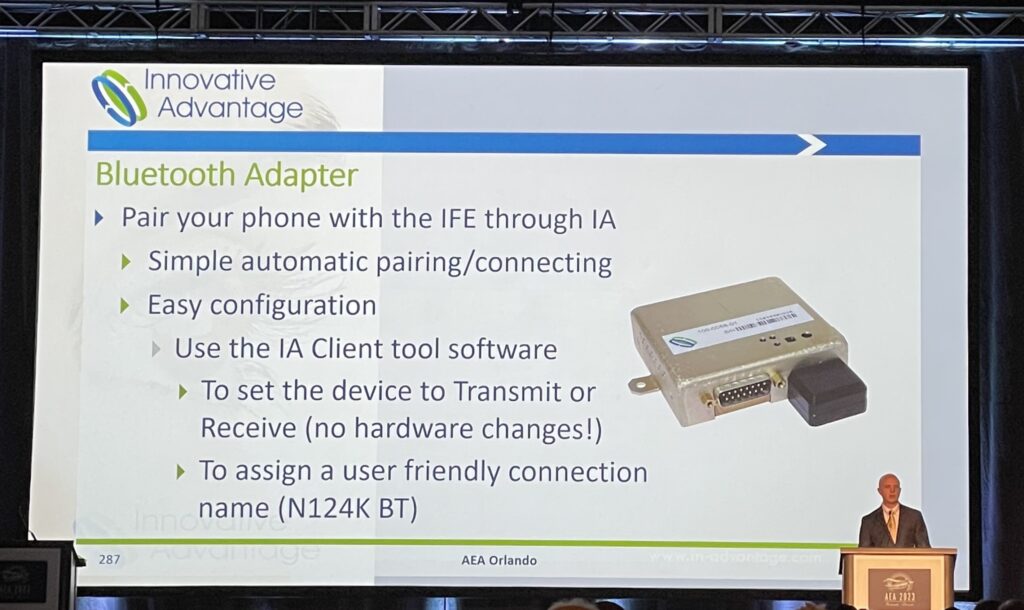

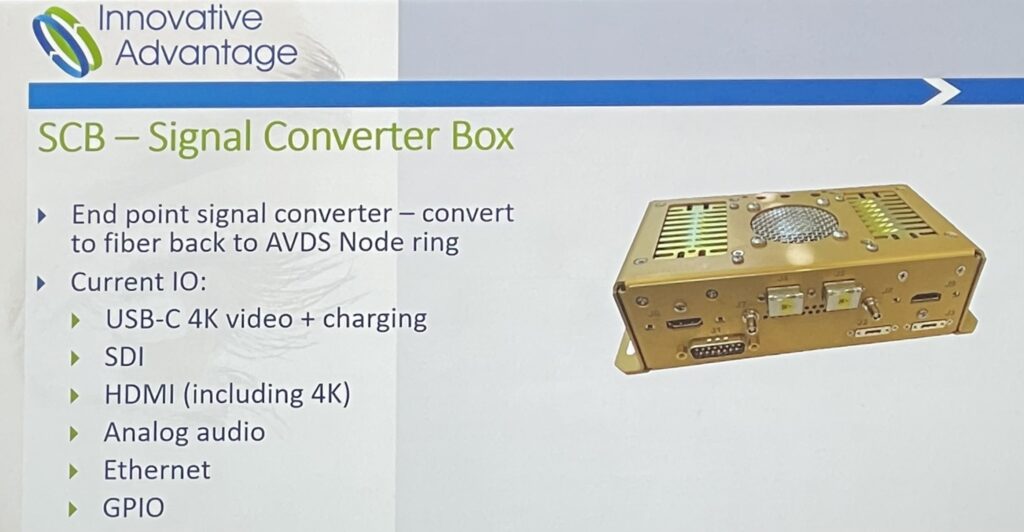

Innovative Advantage

Bill Dalton, Technical Program Manager at Innovative Advantage, covered the company’s Audio Video Distribution System (AVDS) Node Box in addition to new offerings: a Bluetooth adapter that enables customers to listen to music with their wireless headphones via the IFE system; an HDMI Consumer Electronics Control (CEC); and a Signal Converter Box (SCB).

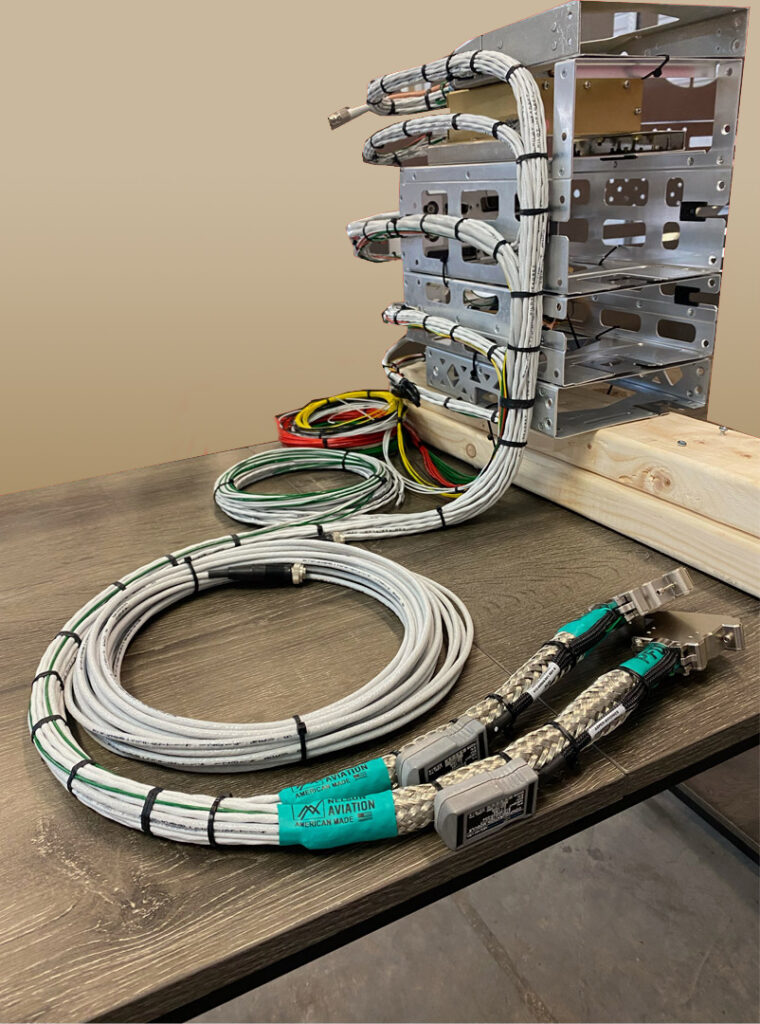

One Mile Up

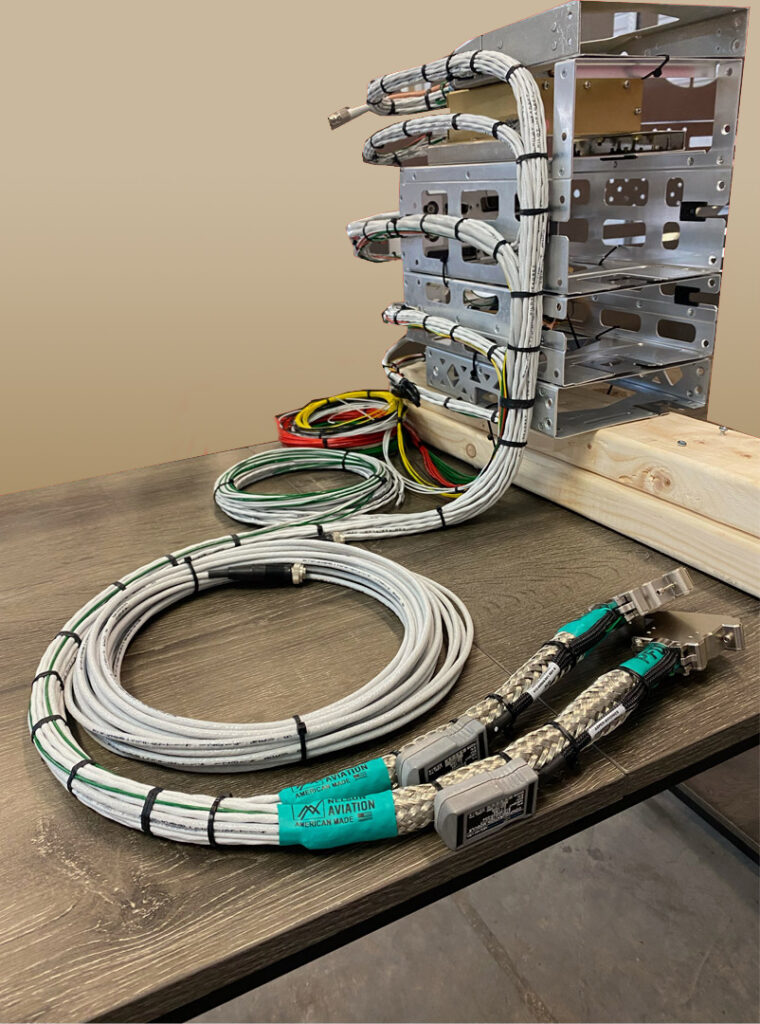

Gene Velazquez, president and founder of One Mile Up, showcased their Panel Planner software that enables users to design and fabricate instrument panels for general aviation. He noted that their booth at the AEA Convention is displaying new products, including the Harness Planner, which is produced at Nelson Aviation’s wiring harness production facility in Florida.

Panel Planner (Photo: One Mile Up)

Harness Planner (Photo: One Mile Up)

Laversab

Laversab builds avionics RF and air data test sets. Kerry Nabors, Aviation Systems Manager at Laversab, highlighted the Laversab ARTS-7000, a multifunction all-in-one Avionics Radio Test System (ARTS). The optional GPS simulator offers fixed and motion modes, full-constellation GPS output, and intuitive route creation.

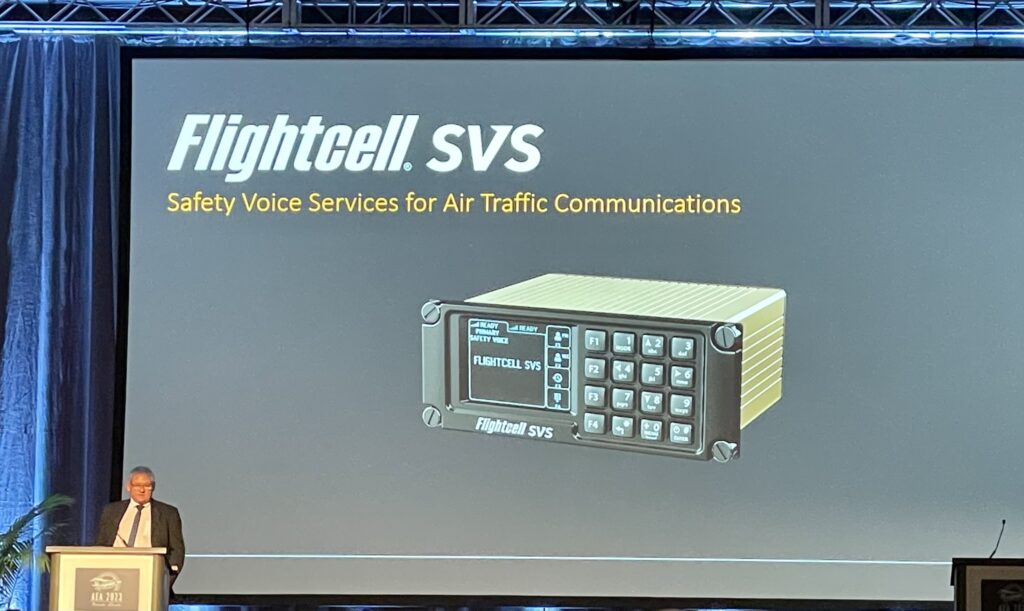

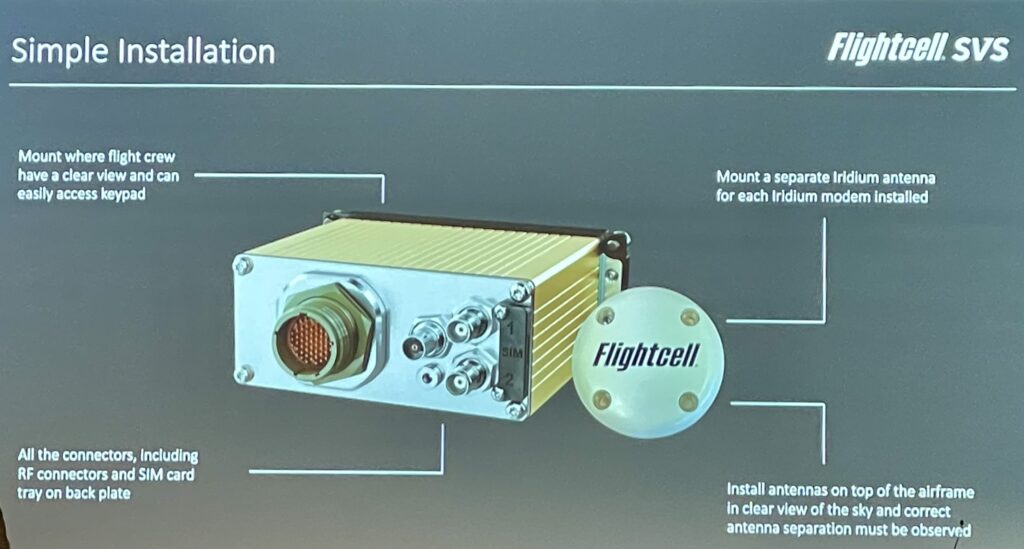

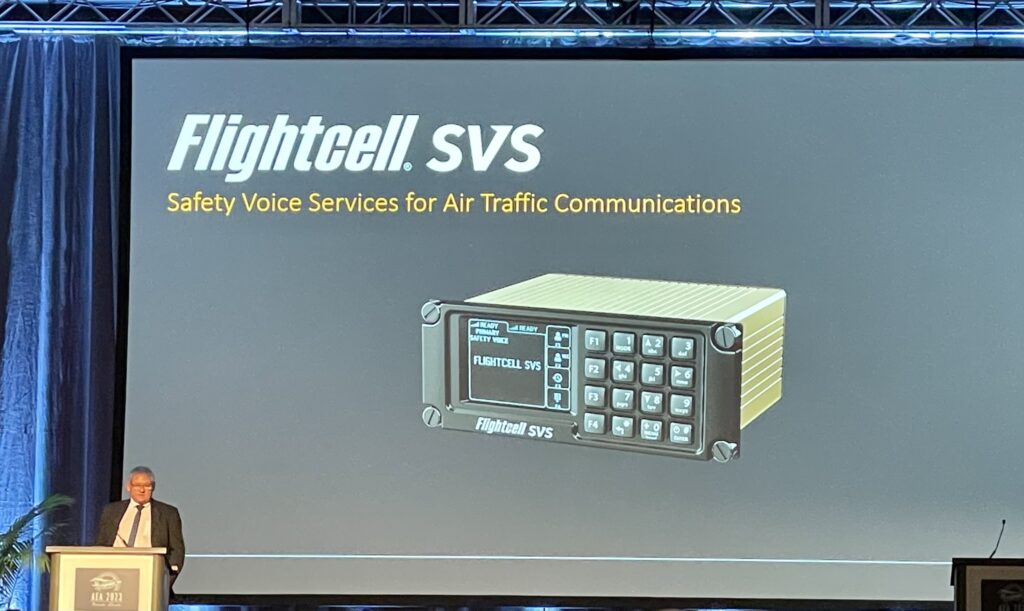

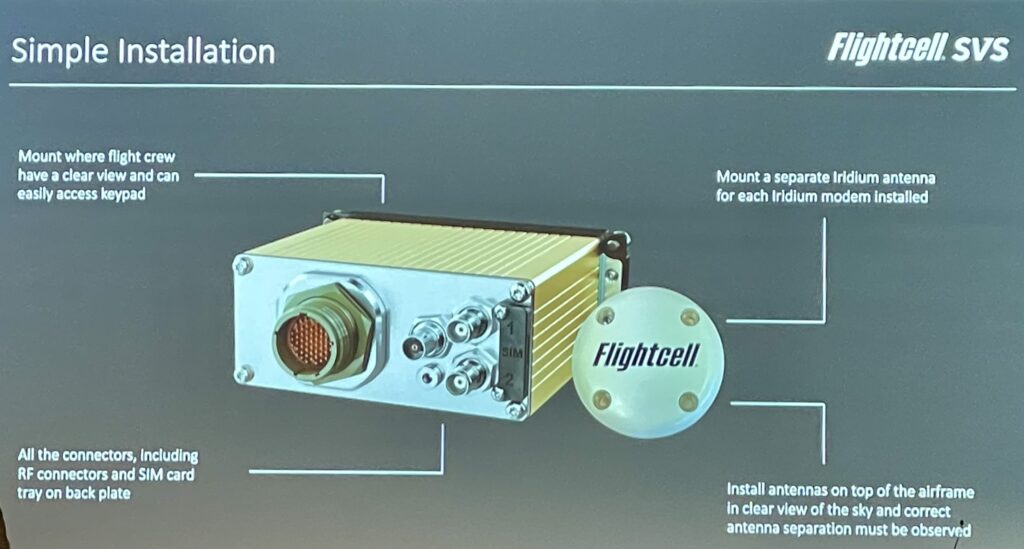

Flightcell

New Zealand-based Flightcell’s latest innovation is an all-in-one satellite voice solution, Flightcell SVS. The product provides worldwide voice communications over the Iridium Satellite network, including bi-directional calling between air traffic control and the aircraft. It also includes safety voice calling levels: emergency, high, low, and no priority.

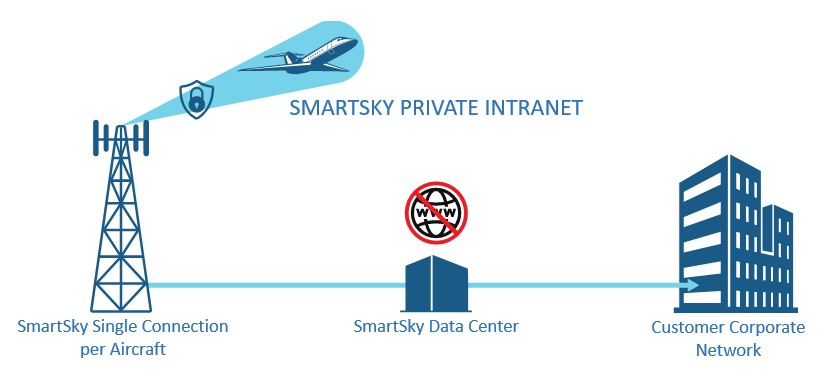

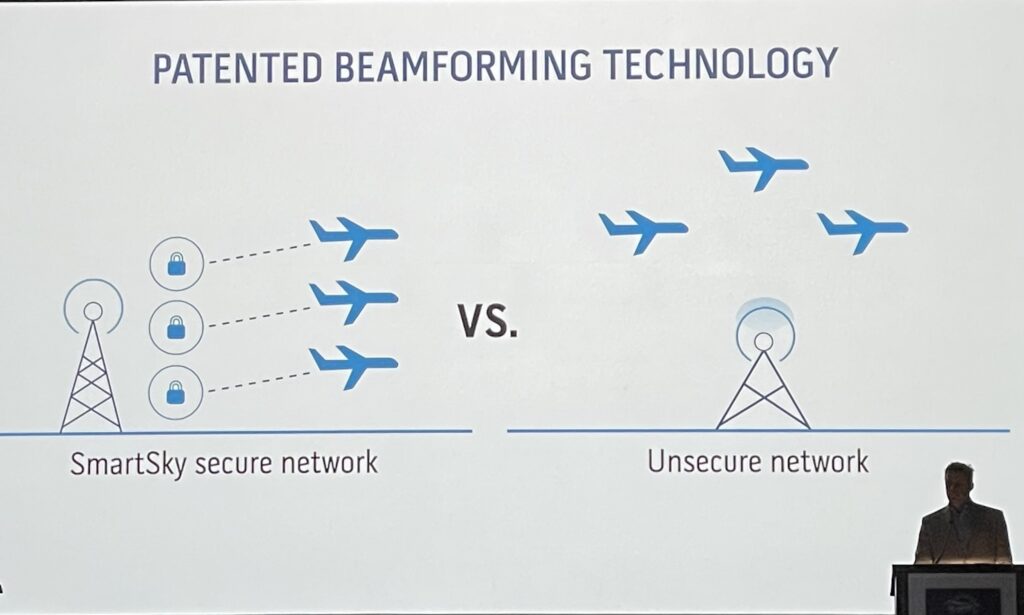

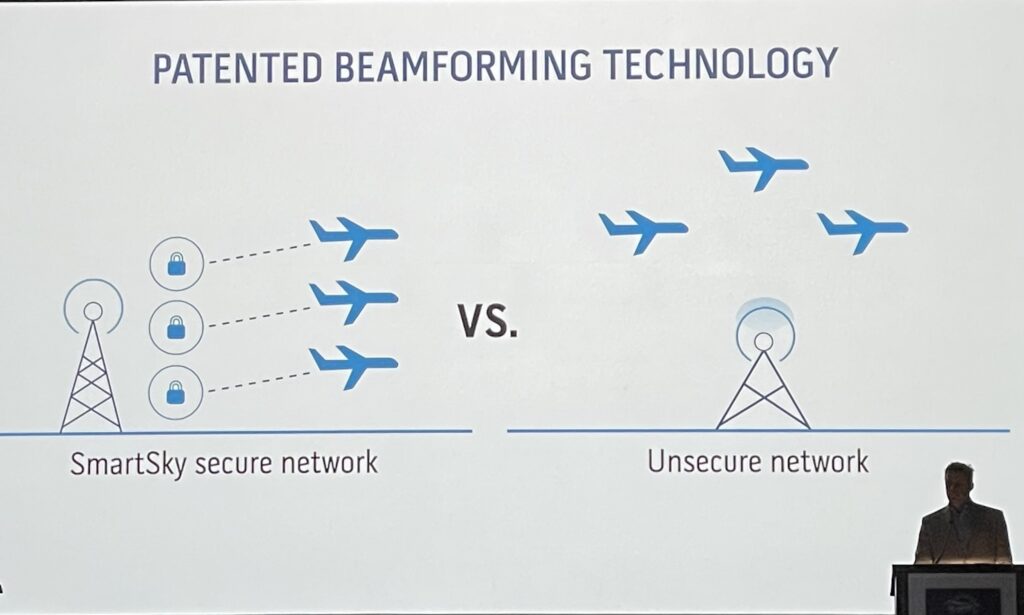

SmartSky Networks

Sean P. Reilly, VP Digital Solutions & Air Transport, introduced a new product from the company: SmartSky Private Intranet. It’s an air-to-ground system with very low latency that enables real-time transfer of data, according to Reilly. It also allows for live streaming, video conferencing, gaming, and sending photos or videos.

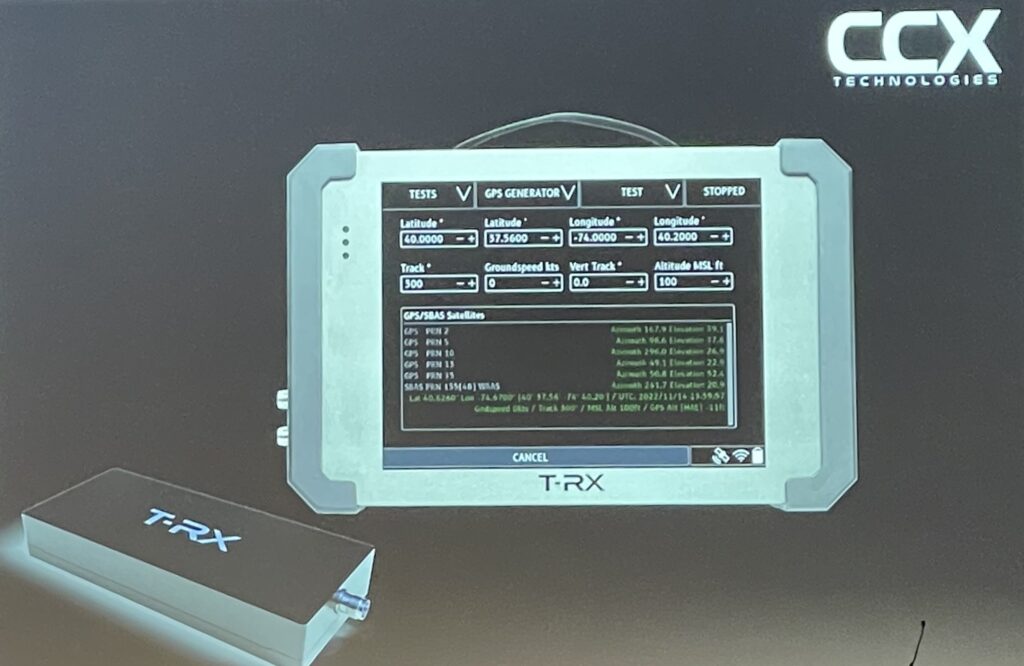

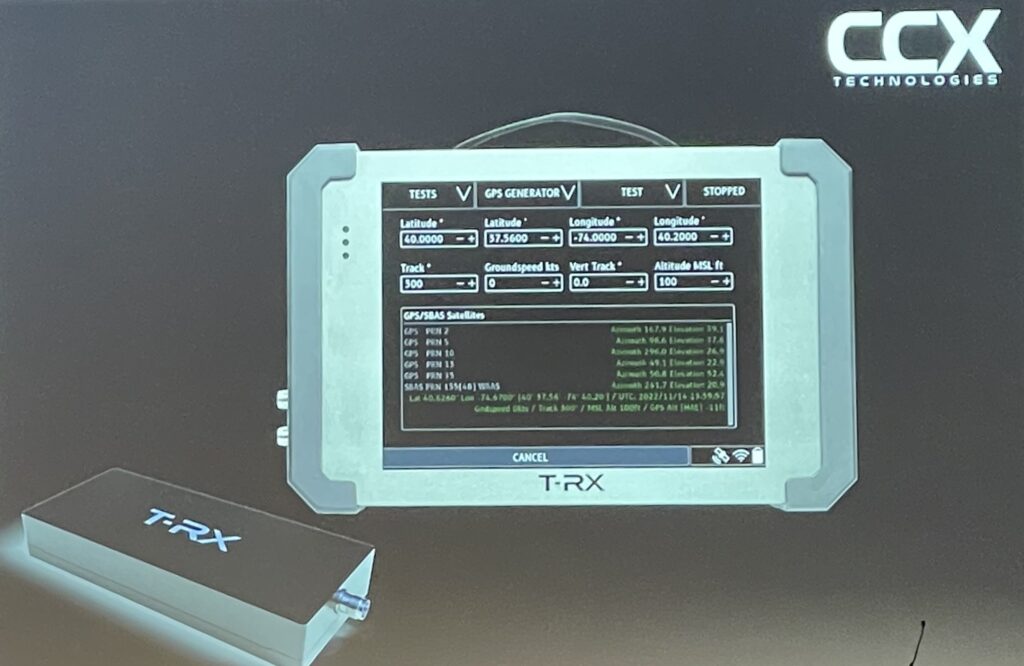

CCX Technologies

CCX unveiled its T-RX GPS to a new audience at the New Product Introductions event this week. The T-RX GPS has previously been showcased at various other events. It has a secure and intuitive user interface, and it’s lightweight and portable. The T-RX GPS also has a software-based architecture that allows for upgrades to the device.

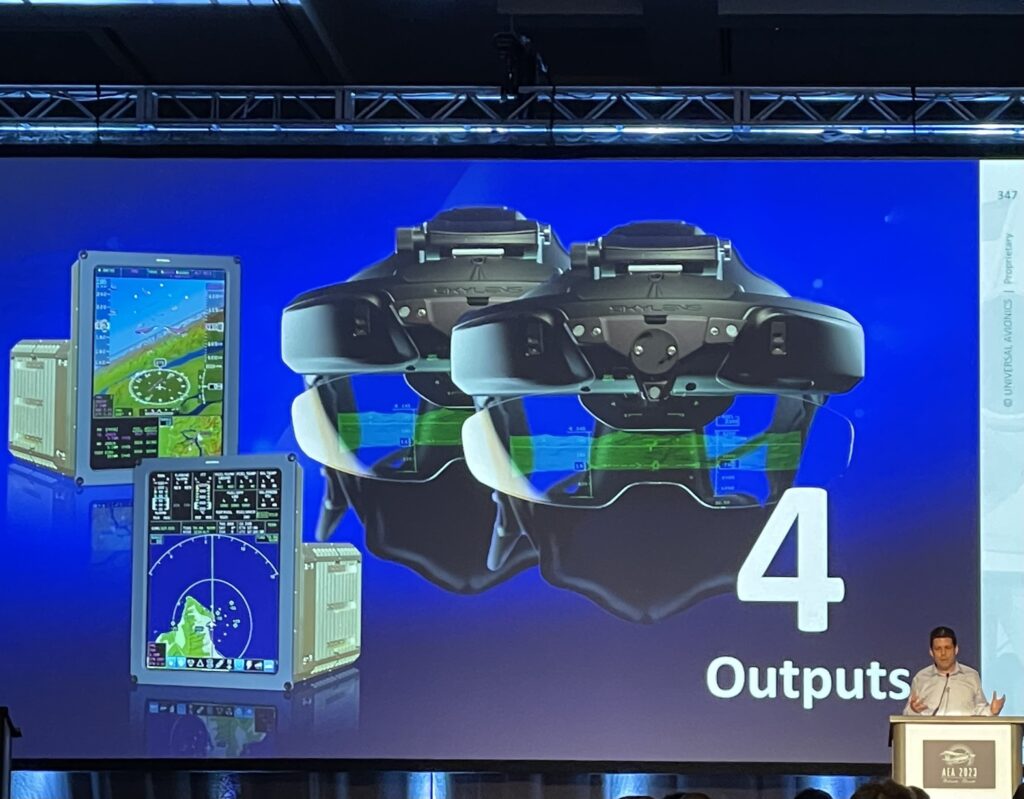

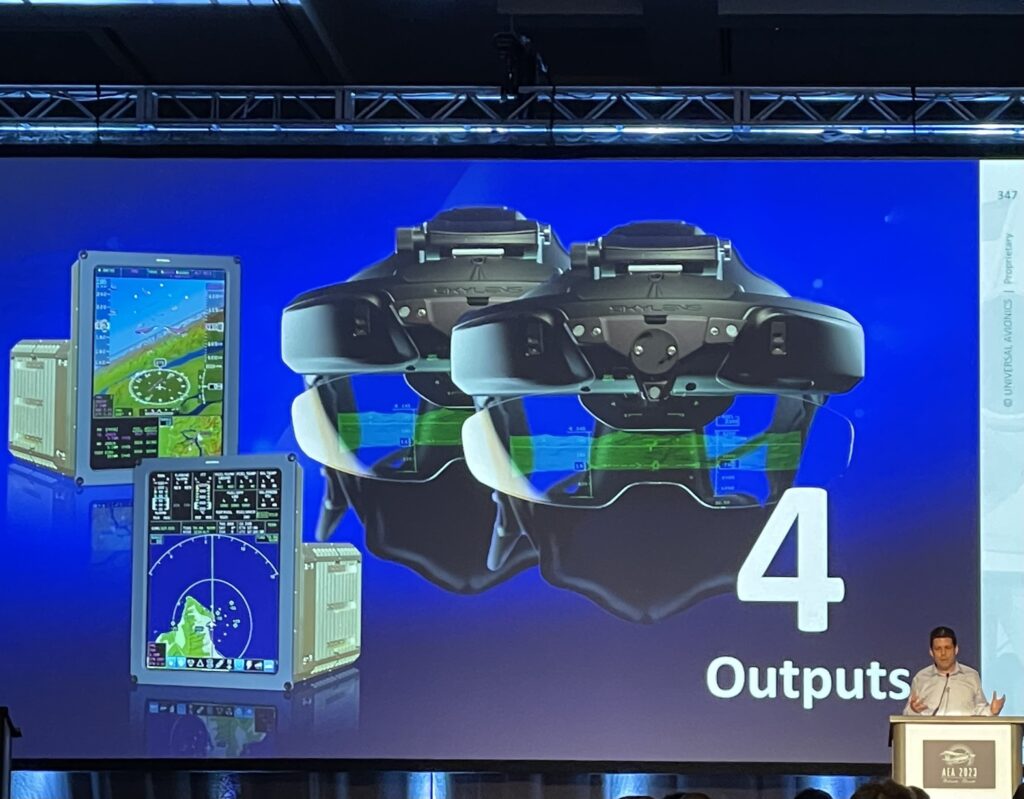

Universal Avionics

Universal Avionics (UA) announced earlier this year that it has received Technical Standard Order (TSO) authorization of the first Aperture visual data management solution as of January. Its optimized hardware includes eight A818 input channels and four A818 output channels. Aperture has a Design Assurance Level A (DAL A), a multi-core CPU, and two X AI dedicated processing units. UA is working to expand capabilities of Aperture to include additional video/sensor channels as well as low latency video aggregation and manipulation.

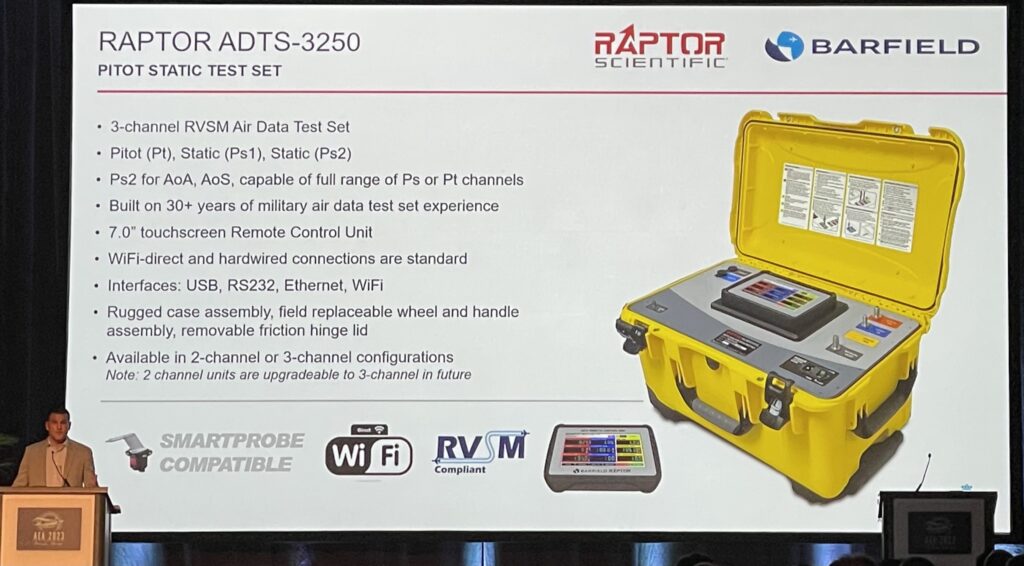

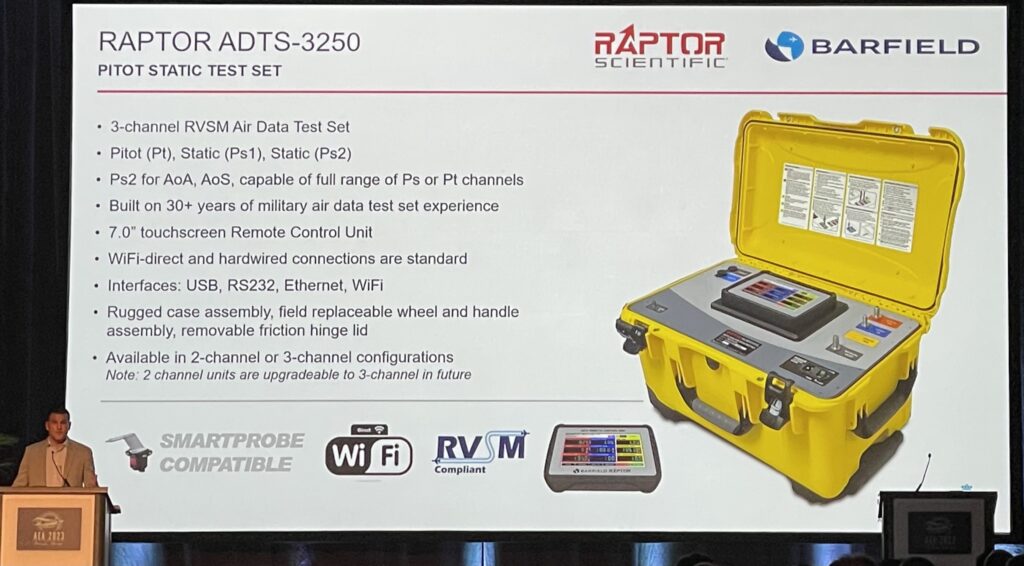

Raptor Scientific

Raptor Scientific provides engineering, testing and measurement services. This includes designing and manufacturing mass properties, air data test technology, and radar cross section measurement instruments. Highlighted at the New Product Introductions event was the Raptor ADTS-3250. Production of this pitot static test set is expected to kick off in June.

The post New Product Introductions at AEA 2023 appeared first on Avionics International.

—————

Boost Internet Speed–

Free Business Hosting–

Free Email Account–

Dropcatch–

Free Secure Email–

Secure Email–

Cheap VOIP Calls–

Free Hosting–

Boost Inflight Wifi–

Premium Domains–

Free Domains