OPINION: Critical Cleaning Helps to Propel Avionics Reliability

It is critical that the Printed Circuit Board Assemblies (PCBAs) inside avionics systems work long-term without interruption. In this opinion article, Emily Peck provides some insight on the importance of ensuring PCBAs inside avionics systems are properly cleaned to ensure long-term reliability and performance.

Avionics helps to control just about every part of an aircraft. From communication, monitoring and navigation, to flight control, collision avoidance and fuel and weather systems; avionics are integral to an aircraft’s functionality. It goes without saying that because of its importance, components used within avionics must be manufactured precisely to ensure reliability. There is no room for error as the consequences would be catastrophic.

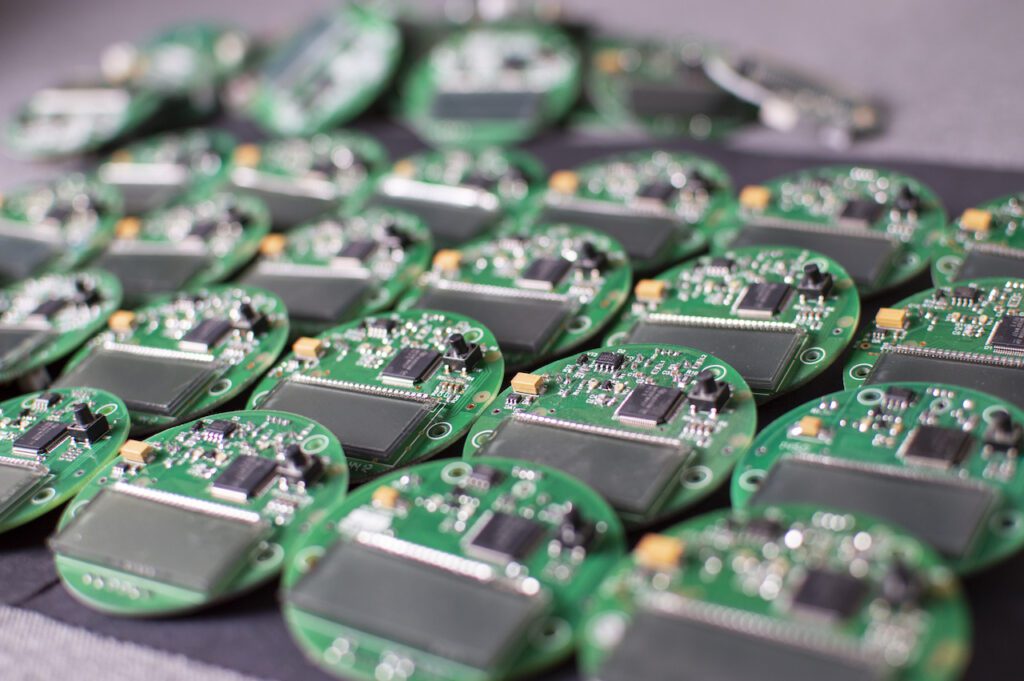

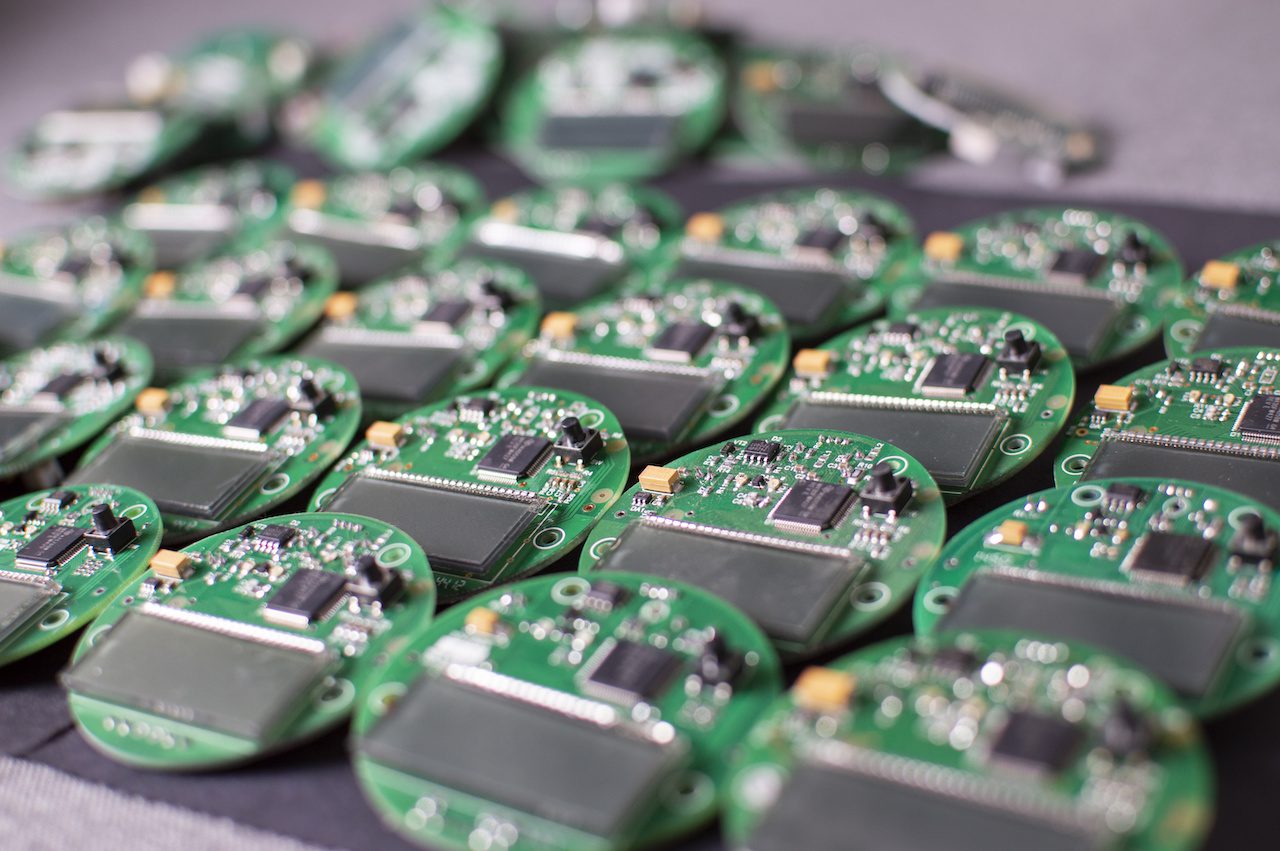

It is critical that the PCBAs (Printed Circuit Board Assemblies) inside avionics systems work long-term, and continue to work, without interruption. A key step in the challenge to guarantee reliability is precision cleaning.

Contamination – A Main Cause of PCBA Failure

Production of avionics systems must include precision manufacturing and the accurate assembly of highly complex PCBAs. Components used within avionics require not just long-term functionality, but they must also stand up to rigorous regulations and standards. One example is IPC-A-610 Class 3. This is the highest standard of the IPC (Institute for Interconnecting and Packaging Electronic Circuits) with the most stringent manufacturing requirements. This standard is aimed at products whose performance is critical, for example in aerospace and military applications.

On top of that, there is the challenge of ensuring the PCBA withstands the harsh conditions found in aircraft including extreme temperatures and high humidity to radiation, chemicals and excessive shock and vibration.

Furthermore, avionics are becoming smaller and more multifaceted. The increasing demand for miniaturized PCBAs to operate modern avionics systems, and the extremely complex nature of these assemblies, which incorporate delicate components on compact, densely-packed boards, can prove to be a reliability risk if not manufactured and assembled correctly.

One of the main causes of electronic device failure is contamination of the PCBA. The smallest amount of debris can form a barrier between electrical contacts. If the contamination isn’t cleaned, the PCBAs run the risk of intermittent or complete field failure. Dirty PCBAs are susceptible to a whole host of problems. This can include everything from electrochemical migration and delamination to parasitic leakage, dendrite growth and shorting. This is why cleaning is crucial to ensuring the reliability of a device, but it is becoming increasingly more challenging as PCBAs become smaller and smaller.

Finding a Process that Critically Cleans

All PCBAs in the aerospace sector require cleaning during production to remove contaminants like flux, dust, marking inks, oils or inorganic contamination resulting from the manufacturing process. This, however, is more difficult due to the reduced PCBA’s size and complexity.

Smaller assemblies housing PCBAs that are multi-layered with hard-to-reach areas makes cleaning extra tough. Removing contamination under and around tightly-spaced components is difficult and can lead to a greater likelihood for insufficient, weak solder joints, bridging, and dendrite growth. If the contaminant is not cleaned properly the risk of board malfunction is high. It is, therefore, crucial to ensure cleaning procedures are in place and work effectively to guarantee clean boards every time.

Finding a cleaning process that ensures critical cleaning is completed successfully can be a challenge. There are many factors that must be considered. It needs to be a process that can easily and reliably clean miniaturized electronic assemblies and meet specific cleaning standards. It must also be a method that is sustainable and cost-effective.

One of the most reliable methods to effectively clean PCBAs is with a vapor degreaser. Vapor degreasing not only ensures the cleanliness of the PCBA, but also meets the economic and regulatory requirements within aerospace and aviation manufacturing.

The Mechanics of a Vapor Degreaser

Vapor degreasers offer a simple process that is very successful at removing contaminants. When used with advanced cleaning fluids it is extremely effective at thoroughly removing contamination from every area of the PCBAs.

A vapor degreasing machine contains two chambers, a boil sump and a rinse sump. In the boil sump, the cleaning fluid is heated and the parts are immersed and cleaned in the fluid. Once cleaned, the parts are mechanically transferred into the rinse sump for a final clean in a pure, uncontaminated fluid.

The cleaning fluids used within the system have multiple chemical properties that are advantageous to critical cleaning. The low viscosity and surface tension ratings of modern cleaning fluids used within a vapor degreaser, combined with their volatility, allow them to easily infiltrate and clean very tight spaces like BGAs, MLFs, QFNs, and D-Paks often found within avionics assemblies. Most vapor degreasing fluids also are very heavy and dense, typically 20-40% heavier than water used in aqueous cleaning. This aids in dislodging particulate from the components, an important factor when cleaning mission critical PCBAs.

Critically for PCBAs found within avionics, vapor degreasing can handle the most challenging and complex shapes with the parts coming out clean, dry and spot-free to ensure they meet specific standards like IPC-A-610 Class 3.

Future-Proof Cleaning for Reliable Avionics

There is no question that the aerospace industry is reliant on high-performing printed circuit boards. Avionics, and the PCBAs used within them, enable aircraft to be automated, safer and more intuitive thanks to its cutting-edge technology. Avionics will continue to be critically important as the industry pushes towards the next generation of aircraft and the idea of autonomous flight.

As avionics plays a bigger role, the importance of ensuring these systems, with their complex miniaturized PCBAs, work unfailingly becomes even more important, particularly in an industry where the smallest margin of error could mean a life-threatening outcome.

A critical step to ensure PCBA functionality is through cleaning. Vapor degreasing is an effective solution to increasing quality and reliability. It ensures contaminated PCBAs are not the cause of device failures. The advanced next-generation cleaning fluids used within the vapor degreaser allow for better PCBAs to be built and deployed, therefore creating new capabilities for the future of avionics.

Emily Peck is a senior chemist at MicroCare, LLC, she has been in the industry more than six years and holds a MS in Chemistry from Tufts University.

The post OPINION: Critical Cleaning Helps to Propel Avionics Reliability appeared first on Aviation Today.

—————

Boost Internet Speed–

Free Business Hosting–

Free Email Account–

Dropcatch–

Free Secure Email–

Secure Email–

Cheap VOIP Calls–

Free Hosting–

Boost Inflight Wifi–

Premium Domains–

Free Domains