Frontier and Spirit Airlines Reach Merger Agreement to Become Fifth Largest US Airline

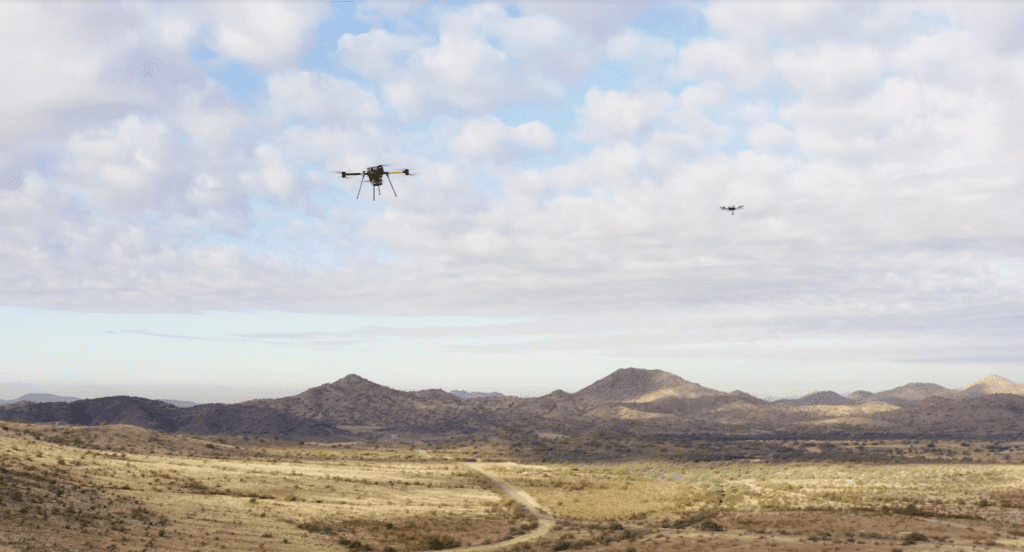

A new merger agreement between Frontier and Spirit Airlines announced Monday would create the fifth largest airline in the U.S., with Frontier holding a majority 51.5% ownership stake in the merged ultra low cost carrier. (Frontier Airlines)

Frontier and Spirit Airlines have reached a definitive merger agreement under which the two companies will combine—if approved by regulators—to establish the fifth largest airline in the U.S.

The two low-cost carriers announced the new agreement Monday that would give Frontier a 51.5% controlling ownership share, with Spirit holding the remaining 48.5%. Both airlines expect the merger to close by the second half of 2022, and will continue to operate independently as Frontier and Spirit while awaiting final regulatory approval of the merger agreement.

Barry Biffle, President and CEO of Frontier, told investors during a call about the merger, “Spirit is very strong in the east, Frontier is very strong in the west, that’s going to drive more customers onto our existing flights which means more low fares to more people.”

Fleet commonality between the two All-Airbus A320 low-cost operators was also highlighted by executives during the investors’ call. Between the two airlines, the combined fleet currently features 283 in-service aircraft with a combined outstanding order book for another 350 A320neo aircraft.

That would give the merged Frontier-Spirit airline a combined 493 aircraft in-service by 2026. According to Frontier, that would allow the merged airline to “offer more than 1,000 daily flights to over 145 destinations in 19 countries, across complementary networks.” Frontier also made some fleet technology investments last year, including adoption of the Airbus Skywise Health Monitoring (SHM) technology, and FLYHT’s Automated Flight Information Reporting System (AFIRS).

Ted Christie, President and CEO of Spirit, said the two airlines expect nearly 80% of their fleet to feature A320neo jets that replace legacy A320s operated by the two carriers. Christie said that the Miramar, Florida-based company is “thrilled to join forces with Frontier to further democratize air travel.”

Frontier and Spirit have a combined 350 A320neo aircraft on order, which would give them a combined 483 aircraft by 2026, if the merger achieves regulatory approval. Pictured here is the interior of a Spirit Airlines A320neo aircraft. (Spirit)

“Both of us have an objective to achieve pre-pandemic margins and we feel like that’s achievable, and when we do, the synergies are purely accretive,” Christie said during the investors’ call.

The merger agreement comes as both carriers separately reported net losses in their 2021 full-year earnings. Spirit reported a loss of $440.6 million, while Frontier lost $299 million.

Together, the combined low-cost airline wants to take on the “Big Four” U.S. airlines, as their combined fleet and operational scope would see them move above Alaska and JetBlue for fifth place among the largest airlines in the U.S.

The “Big Four,” as Frontier and Spirit executives described them during the investors’ call, include American, Delta, United, and Southwest Airlines. These four carriers controlled 74% of revenue passenger miles flown by U.S. airlines in 2019, according to U.S. Department of Transportation data.

2021 was also a year that saw several new low-cost U.S. airlines begin operations, including Avelo Airlines, Breeze Airways, and Aha!

When asked by investors about the likelihood of achieving regulatory approval for the merger, Frontier’s Biffle said the two sides are prepared to show regulators that it is “completely different than any other merger in the past in the U.S. It’s not about reducing competition and raising fares, it’s about getting more low fares to more people in more places and we’re excited to tell them our story and we think it will be well received.”

The post Frontier and Spirit Airlines Reach Merger Agreement to Become Fifth Largest US Airline appeared first on Aviation Today.

—————

Boost Internet Speed–

Free Business Hosting–

Free Email Account–

Dropcatch–

Free Secure Email–

Secure Email–

Cheap VOIP Calls–

Free Hosting–

Boost Inflight Wifi–

Premium Domains–

Free Domains

services,” according to GE Aviation’s announcement of the new selection.

services,” according to GE Aviation’s announcement of the new selection.