Trends in the state legislative sessions related to UAS include discussions about drone operations over critical infrastructure, police use, new AAM study committees, country-of-origin bans, and vertiports. (Photo: AUVSI)

BALTIMORE, Maryland — In an ever-evolving drone industry landscape, state and local legislators are grappling with creating effective and fair regulations for uncrewed aircraft systems (UAS). In the wake of the Federal Aviation Administration’s 2023 Fact Sheet on State and Local Regulation of UAS, we have seen a variety of responses—some fostering growth, others seemingly encroaching on federal authorities. To navigate this complex environment, the Association for Uncrewed Vehicle Systems International (AUVSI) launched Drone Prepared, a 50-state educational initiative aimed at guiding lawmakers in crafting regulations that are industry-supportive and consistent with federal oversight.

Scott Shtofman of AUVSI and Josh Turner of Wiley Rein LLP spoke with Avionics International during this week’s Drone Summit, hosted by the FAA and AUVSI. Shtofman and Turner discussed recent legislative trends including issues related to flight over critical infrastructure, police use, advanced air mobility (AAM) study committees, country of origin bans, and vertiports.

According to Scott Shtofman, Senior Manager of Government Affairs at AUVSI, there has been increased state-level interest in regulating drones and their operations over critical infrastructure. However, “I wouldn’t say that we’ve had changes in how UAS operate over critical infrastructure,” he remarked.

Section 2209 of the FAA Extension, Safety, and Security Act of 2016 is a key reference, intended to establish which sites can be considered critical infrastructure and the regulations for flying over them, although there’s ongoing debate about what should be included in this definition, Shtofman noted.

He believes there will be a lot of interest from both asset owners and users in performing inspections of critical infrastructure using UAS. “There are benefits of being able to collect data using a drone and not having to shut down that piece of infrastructure,” he explained.

There is also a push to expand the definition of critical infrastructure. “Is that beyond something like petroleum refining and production plants or electric substations?” Shtofman asks.

Work is being done on drone detection and mitigation efforts, aiming to establish who has the authority to detect drone presence and act upon an imminent threat. To this end, Michael Robbins—Chief Advocacy Officer at AUVSI—is co-chairing an aviation rulemaking committee around counter-UAS.

(Photo: NUAIR)

Josh Turner from Wiley Rein LLP, a Drone Prepared partner, noted that the FAA has congressional authority and instruction to create rules under Section 2209 that define what constitutes critical infrastructure, but the process has been delayed. “Right now, states tend to set their own ideas of what constitutes critical infrastructure,” he told Avionics.

“It would be great to get some clarity around what those rules are at a national level,” he added. Uniform national understanding and regulation of what constitutes critical infrastructure, as decided by the FAA, would help to prevent confusion.

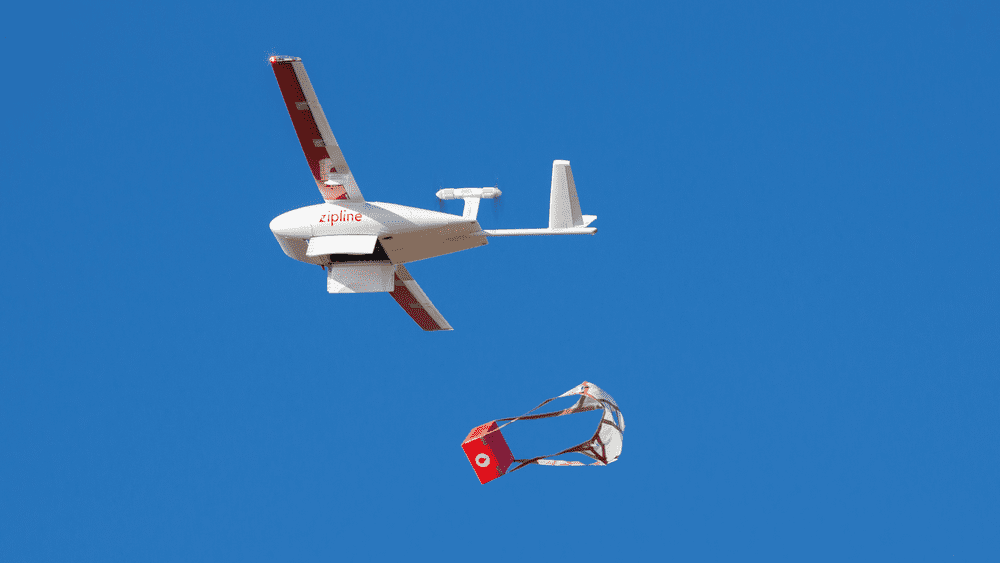

Turner also discussed legislation surrounding vertiports. States have traditionally decided where aircraft can take off and land, a role acknowledged and reinforced by the FAA’s 2023 Fact Sheet. “AUVSI has been very supportive of the idea that states have a role in figuring out how to make urban air mobility and advanced air mobility happen,” he commented.

The Drone Prepared program aims to educate local and state governments on the necessary legislative changes for successful vertiport integration into local communities.

Over the past year, there has been growing interest and successful initiatives in state and local governments around vertiports and urban air mobility. “The idea of having a vertiport in your city or in your state is really compelling,” Turner said.

(Photo: Skyports)

Privacy Concerns and Public Safety

A key goal of AUVSI is to ensure that states understand their rights to protect their citizens’ privacy—without the need for an abundance of new drone-specific rules—and that existing laws can be leveraged to do so.

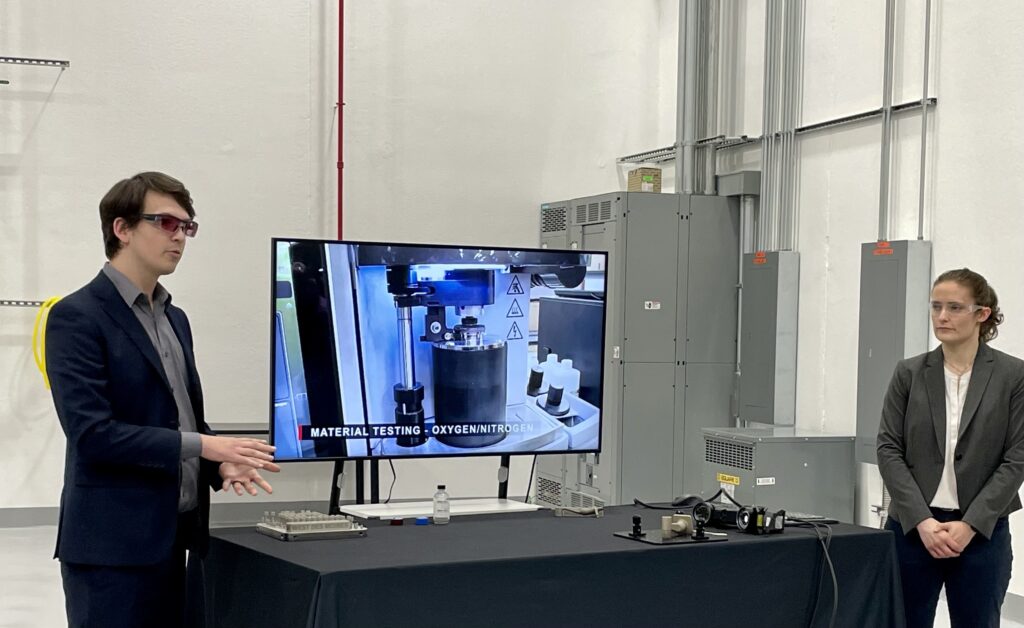

Drones are just another tool, akin to a flying camera. Their use should be governed by the same privacy considerations as any other tool, Shtofman explained. “When it comes to police use of drones, it’s different than commercial use,” he said. “There are already standards in place for what’s required when they want to search something, or if you’re using the drone for surveillance purposes.”

Drones can serve as less risky and less expensive alternatives to helicopters in police operations, providing oversight and helping to de-escalate situations. Transparency is essential regarding how data collected by drones will be used, stored, and shared, which should be clearly communicated to the public to alleviate privacy concerns.

Drones are being used by around 10 to 15 departments across the country as “first responders.” “They’ll send a drone to the site of the call to get an assessment of the situation and decide what sort of response is required by officers,” according to Shtofman.

Open dialogue with communities about drone usage can help dispel fears and misconceptions. He underscored that the primary use of drones by the police is as a tool for better situational understanding and response.

(Photo: Matternet)

Country-of-Origin Bans

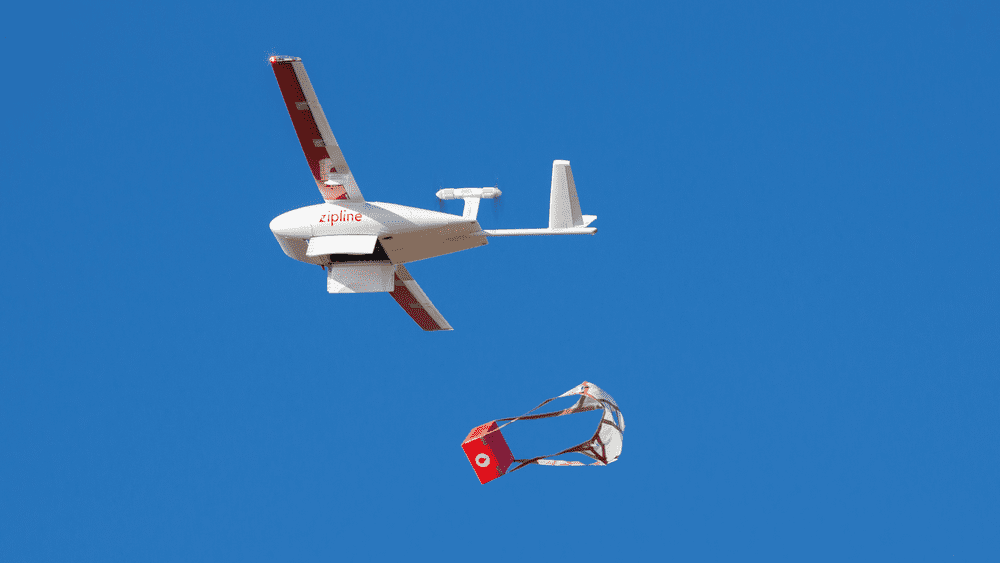

Legitimate security concerns exist around drones manufactured by what can be considered adversary nations, particularly around how these drones are used and the data security implemented, Turner explained.

“I don’t think that […] it makes sense to ban all drones from a certain country. But at the same time, those legitimate national security concerns do need to be addressed,” he said.

There should be policies in place to prevent the use of equipment that could potentially jeopardize national security or have adverse effects on the American public.

Shtofman noted that the country of origin considerations should not be limited to labeling drones from certain places as bad, but should also consider ways to improve the country’s supply chain resilience.

There’s a need for efforts to enhance local production capabilities to ensure that the industry isn’t hindered due to a lack of access to components either domestically or from allied nations. Building a robust, homegrown industry would ensure the availability of reliable drones and the means to produce them even in adverse situations, thereby strengthening both the commercial and defense aspects of the industry.

Developing a domestic talent pool through STEM education is essential to have the required engineers and manufacturing capabilities to meet any needs, he added.

(Photo: Zipline)

Navigating Intersecting Legal Jurisdictions

The Drone Prepared campaign launched last year has been instrumental in opening discussions with states and influencing legislation by providing clear and detailed legal interpretations and arguments, Shtofman shared. They have engaged with at least 20 states and worked with five departments of transportation to educate lawmakers about drone usage and regulation.

The FAA’s UAS Fact Sheet aligns with AUVSI’s perspective on the delineation of power, stating that the federal focus should be on aviation safety and air navigation, while states should address privacy and public protection.

Clear legislation benefits operators and manufacturers by enabling them to offer drone-related services more effectively. Shtofman explained, “Let’s protect the public, but let’s also allow for the benefit of drones and allow for certainty for operators and manufacturers to know how to prepare a state to be ready for an economic opportunity.”

Turner noted that the clarity of federal and state authority in drone regulation, as underlined by the new FAA Fact Sheet, is certainly helpful. Misconceptions and confusion about rules differing for unmanned systems have been clarified, which aligns with the FAA’s historical control over aviation safety and efficient use of airspace.

The Fact Sheet acknowledges local governments’ authority to regulate privacy, without overriding federal aviation control. The fact sheet also indirectly discourages states from designating drone highways, since constant streams of drones flying overhead are unpopular. “People would much rather have a dispersed set of routes,” said Turner, adding, “It diffuses the impact.”

Those looking for an opportunity to get involved can visit droneprepared.org, Shtofman mentioned. “We have all the legislation that we’re tracking. I think last session, we had over 200 pieces of legislation around the country that were in some way related to drones. Just knowing what’s going on where you live is a great way to start.”

—————

Boost Internet Speed–

Free Business Hosting–

Free Email Account–

Dropcatch–

Free Secure Email–

Secure Email–

Cheap VOIP Calls–

Free Hosting–

Boost Inflight Wifi–

Premium Domains–

Free Domains