French Startup Ascendance Raises €21M for Testing, Certification of its Hybrid VTOL

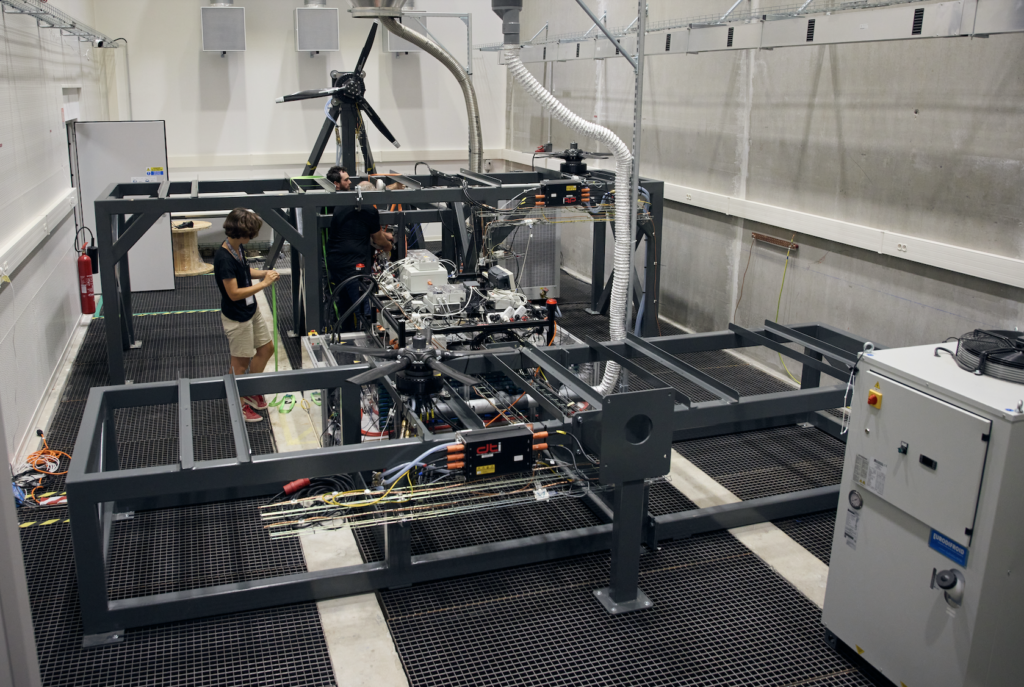

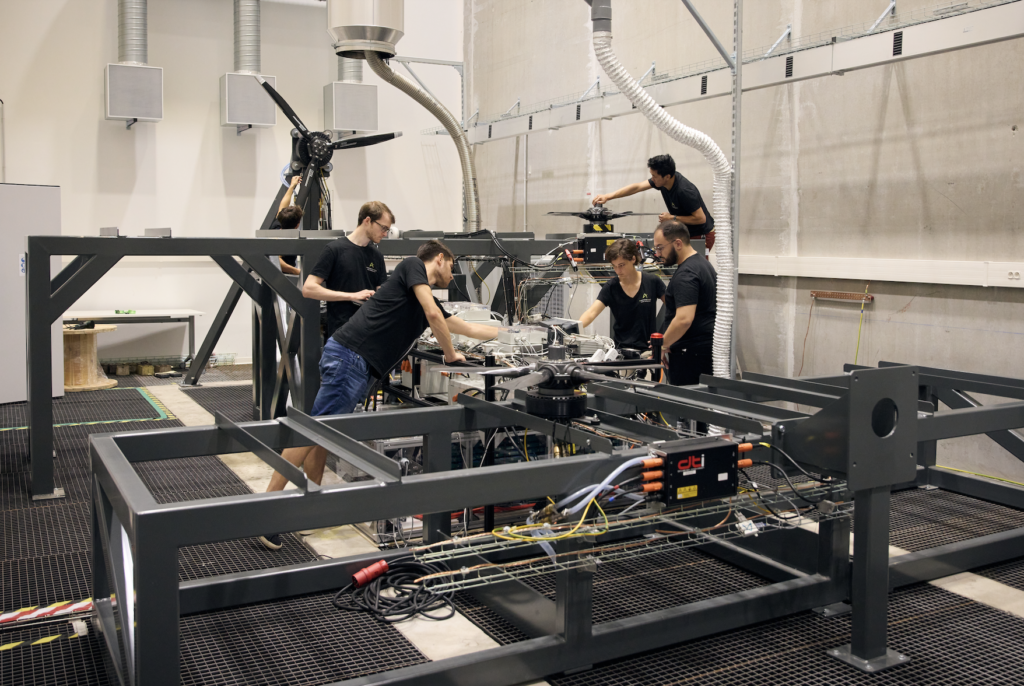

Ascendance Flight Technologies has raised €21 million in funding so far. The startup has developed a full-scale prototype of its VTOL aircraft concept, Atea. (Photos: Ascendance Flight Technologies)

French startup Ascendance Flight Technologies announced in late March that it has raised €21 million (about $22.8M USD) in funding. Ascendance has developed a full-scale prototype of its vertical take-off and landing (VTOL) aircraft concept, Atea. The VTOL leverages the startup’s hybrid propulsion technology—Sterna—to reduce carbon emissions.

The recent fundraising round provided the necessary resources for Ascendance to fly its prototype and begin the certification process. Previous investors Habert Dassault Finance, Céleste Management, IRDI, and M-Capital contributed additional funding to the latest round, as well as new investors ARIS Occitanie, SC Mahé, Adrien Montfort (CTO Sorare) via Snaw Ventures, CELAD, Expansion Aerospace Ventures, and French Tech Souveraineté (operated by Bpifrance).

Ascendance expects to deliver its first aircraft in 2026. The startup is currently in the midst of a prototyping and scaling-up phase. Its integration and test flight facilities have been set up near Toulouse at the Muret – Lherm Aerodrome. In 2022 alone, Ascendance announced that 245 letters of intent had been signed for its Atea aircraft, including an LOI with California-based Flyshare.

Co-founder and Chief Customer Officer Thibault Baldivia and Stéphane Viala, Director of Engineering and Programs, shared more details about the company’s progress and goals via written statements to Avionics International.

Atea, developed by Ascendance, is a low noise, low carbon emissions VTOL aircraft.

Avionics: Can you tell us more about the company’s mission to decarbonize the aviation sector and the unique technologies under development to achieve this goal?

Ascendance is a More Sustainable Aviation pure-player. We are living in the age of environmental concern, and all industries are looking at reducing their carbon footprint. Aviation makes no exception. Ascendance provides the hybrid-electric technology that unlocks the energy transition in aviation to stay in line with passengers’ expectations and the global trend.

Ascendance’s hybrid-electric technology—STERNA—is based on a mix of two energy sources: battery electric and another fuel that can be, [in the] short-term, sustainable aviation fuel [SAF]—or hydrogen tomorrow. STERNA allows aircraft manufacturers to develop new-generation aircraft with a reduced environmental footprint or incremental development on existing platforms.

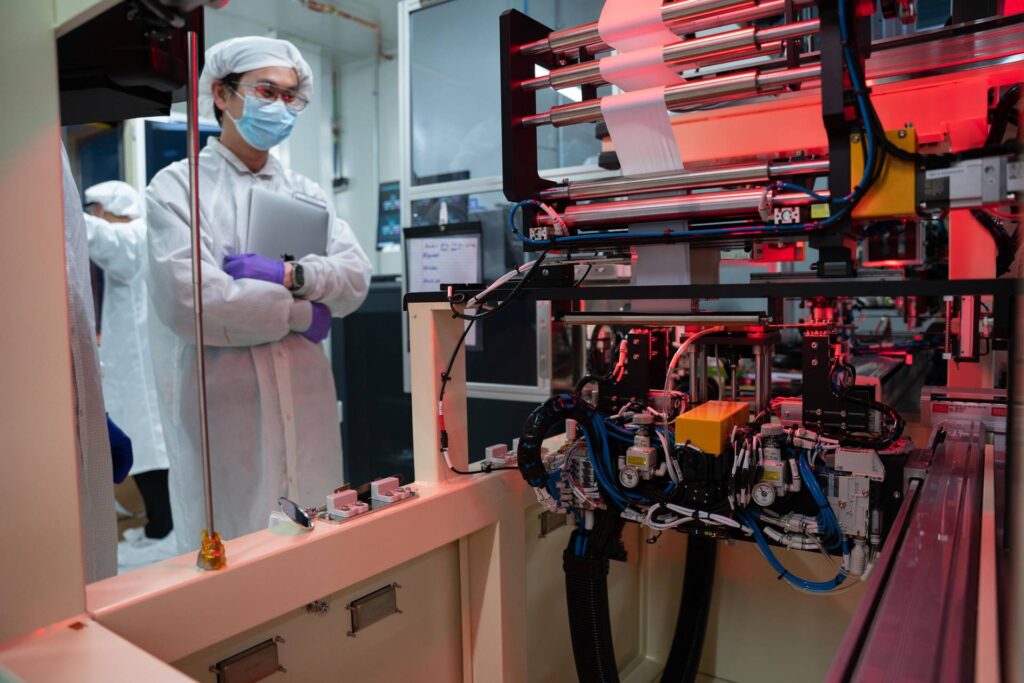

The team at Ascendance works on Sterna, its unique modular hybrid propulsion technology.

The hybrid technology is the only short- to mid-term answer if you want to keep range while decarbonizing. The idea is to be as frugal as possible on the SAF thermal machine, which is always running at its optimum, while complementing it with an electrical source of energy. This technology is scalable to any size of A/C and any type of hybridization: serial or parallel.

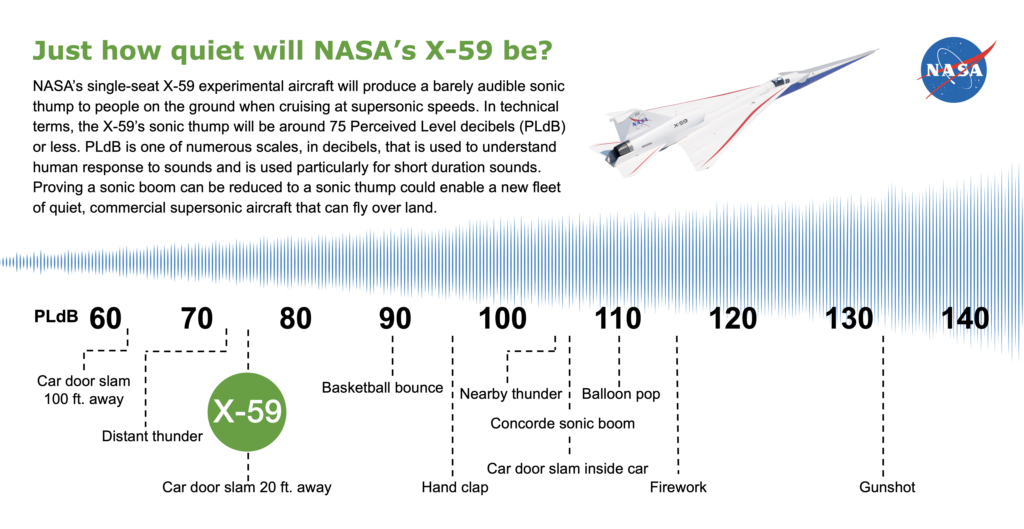

To lead by example in this transition and spearhead the deployment of more sustainable aircraft, Ascendance is also developing a hybrid-electric eVTOL aircraft named ATEA. This aircraft takes off and lands vertically or conventionally thanks to its fixed-wing concept and is a low-noise (divided by 4), low carbon (-80% CO2) alternative to helicopters.

This aircraft can also be used for regional air mobility thanks to its low environmental footprint to develop a new, decentralized aviation to connect remote communities or underserved regions with an efficient, quick, and more sustainable alternative than current transportation options.

Ascendance’s ambition is to be the technology supplier that will be the enabler for the entire industry to succeed in its transition towards another model in a short- to medium-term.

Avionics: How does Ascendance plan to use the €21 million in funding to achieve the company’s goals?

Ascendance: This funding will be used to fly our 1:1 flying prototype with a pilot onboard for ATEA following an extensive period of ground testing and sub-scale prototyping that allowed us to de-risk the overall concept. Our flight test center has just been delivered Q1 2023 and the first parts of the aircraft are expected at the beginning of 2024 for a first flight in 2024.

This funding will also be the opportunity to deliver on our first co-development contracts for STERNA where our technology is applied to new or incremental aircraft developments by our customers. Finally, flying a prototype requires an experienced, talented team that we are currently expanding to reach 100 by next year.

What challenges do you foresee in bringing your hybrid technology to market?

Of course, technological challenges will always be present, but we have a high level of confidence in our technologies due to extensive ground testing at real-scale on our Iron Bird. Regulation is always a challenge in any new aircraft development but we’ve been in contact with the EASA to ensure a clear road to certification.

The biggest challenge—especially in the current economic context—might be financial. We will need additional funding to get to certification, build our industrial capability, and compete with our competitors, especially in the U.S. and Germany.

Can you discuss the progress you’ve made so far in building your full-scale prototype and obtaining certification from EASA?

Thanks to wind tunnel test campaigns (two already completed), full-scale half-wing with fan in wing, and scale one energy storage and distribution, we’ve been de-risking all the key and most innovative technologies. Several patents were drafted accordingly. We are now passing and completing the CDR (Critical Design Review) allowing us to start ordering all long lead time items of the prototype as well as starting to design the details.

Partnerships are under finalization in order to accelerate our development. At the same time, we are deploying the DOA organization targeting the type certification while discussing with EASA and French DGAC to secure the permit to fly for next year. We are relying on the SC VTOL published in 2019 with associated MOC (Mean of Compliance) for which the last updates were done at the end of last year.

How do you see your company’s hybrid propulsion system fitting into the larger picture of sustainable aviation?

We went hybrid-electric because the founding team has been experimenting with electric aircraft since 2015. We quickly saw the limitations of all-electric aircraft for the global decarbonization roadmap of aviation: battery weight and recharge time that limit operations. It is also difficult to scale from two-seater trainer aircraft to something bigger. Hybrid-electric solves these challenges and has the capability to scale (using different powertrain and motor technologies, of course) from turboprop aircraft to regional aircraft as soon as 2027–2030.

We offer our STERNA technology—centered around a very specific and patented Hybrid Operating System (which manages the energy in the aircraft)—to aircraft and helicopter manufacturers to embed this disruptive technology into their new development, incremental development, or to retrofit their existing programs.

How do you plan to scale up your operations and production to meet the growing demand for sustainable aviation solutions?

We already have a pool of international customers that help us better understand the requirements from different parts of the world. We are looking at expanding this pool of first adopters.

At the current stage, we are defining the entire ecosystem around the aircraft and our technologies with the help of partners on infrastructure, customer service and maintenance, pilot training, et cetera, with partners such as Groupe ADP on infrastructure or Air France Industries on maintenance.

When it comes to industrialization, we made a strong choice to hire Hussein Harb (formerly with Gulfstream, Icon Aircraft, and Volocopter) to plan our production roadmap. We are in advanced discussion for a first final assembly line in France.

What kinds of partnerships or collaborations are you seeking to help integrate your hybrid propulsion system into existing aircraft?

We are looking to partner with aircraft or helicopter manufacturers (OEMs) to co-develop the future generation of hybrid-electric aircraft—either on new developments that would bring new aircraft to market, or an incremental evolution of the manufacturer’s product.

The post French Startup Ascendance Raises €21M for Testing, Certification of its Hybrid VTOL appeared first on Avionics International.

—————

Boost Internet Speed–

Free Business Hosting–

Free Email Account–

Dropcatch–

Free Secure Email–

Secure Email–

Cheap VOIP Calls–

Free Hosting–

Boost Inflight Wifi–

Premium Domains–

Free Domains